Method for directly testing permeability of underground coal seam

A test method and permeability technology, which is applied in the field of gas (coal bed methane) basic parameter testing, can solve the problems of high cost, unrepresentative test results, large differences in permeability, etc., and achieve the effect of fast data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

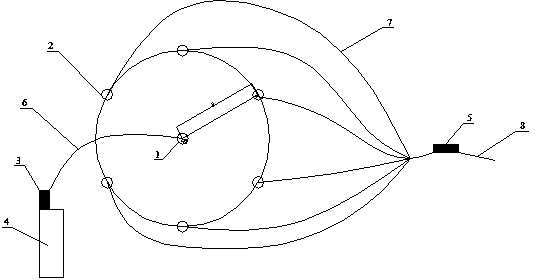

[0016] Embodiment: A coal mine 25051 lower floor drainage roadway in Anyang mining area constructs a layer-penetrating drill hole with a diameter of φ75mm perpendicular to the coal seam as the air supply hole 1, and constructs six borehole diameters evenly distributed on a circle that is 1m away from the center line of the air supply hole The layer-through drilling of φ75mm is used as the air outlet hole 2, and the center line of the air outlet hole is parallel to the center line of the air supply hole. The thickness of the coal seam in this area is 5m, the downhole temperature is 25°C, and the nitrogen viscosity coefficient μ=17.812μPa·s.

[0017] 1. Drilling hole diameter: 75mm, drilling radius: r=0.075 / 2=0.0375m,

[0018] Thickness of coal seam: h=5m, distance from the central gas supply hole to peripheral holes: R=1m,

[0019] formula Middle L=R-2r=1-0.075=0.925m,

[0020] A=2π(R-2r)h=29.045m 2 .

[0021] 2. Test process

[0022] When testing downhole:

[0023] (1)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com