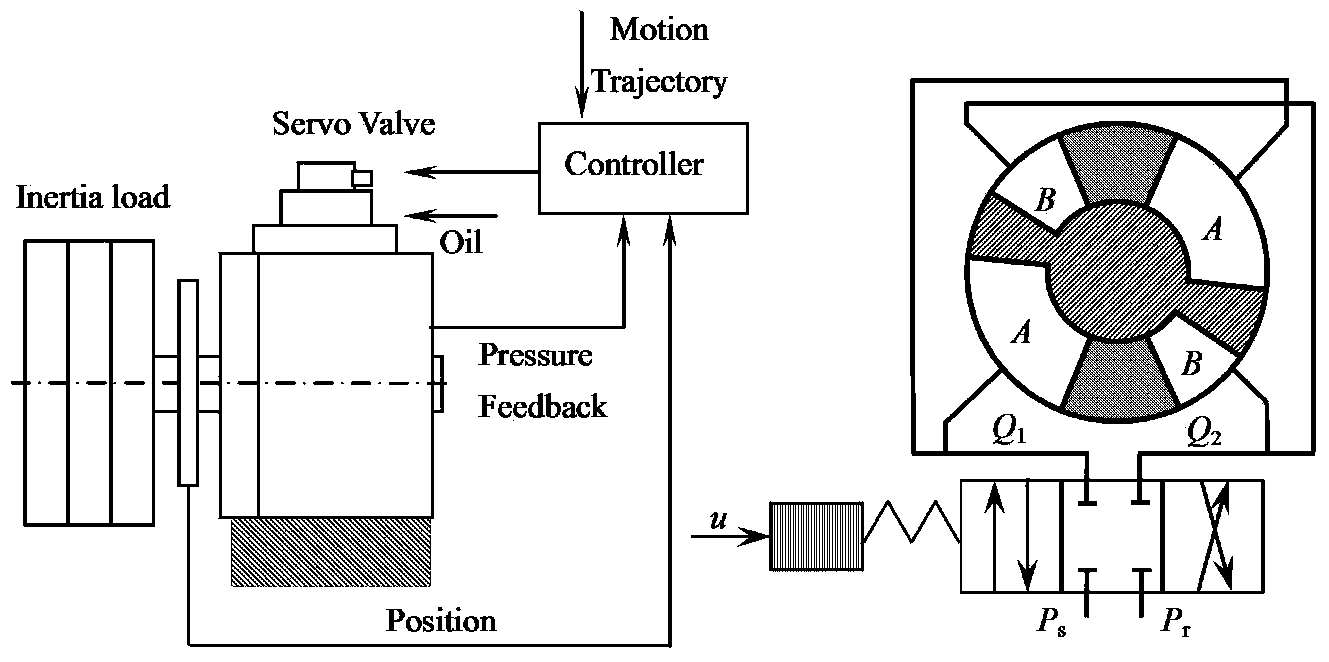

ADRAC (active-disturbance-rejection adaptive control) method for hydraulic motor position servo system

A technology of adaptive control and adaptive controller, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve problems such as controller performance deterioration, achieve good tracking performance, overcome conservatism, and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

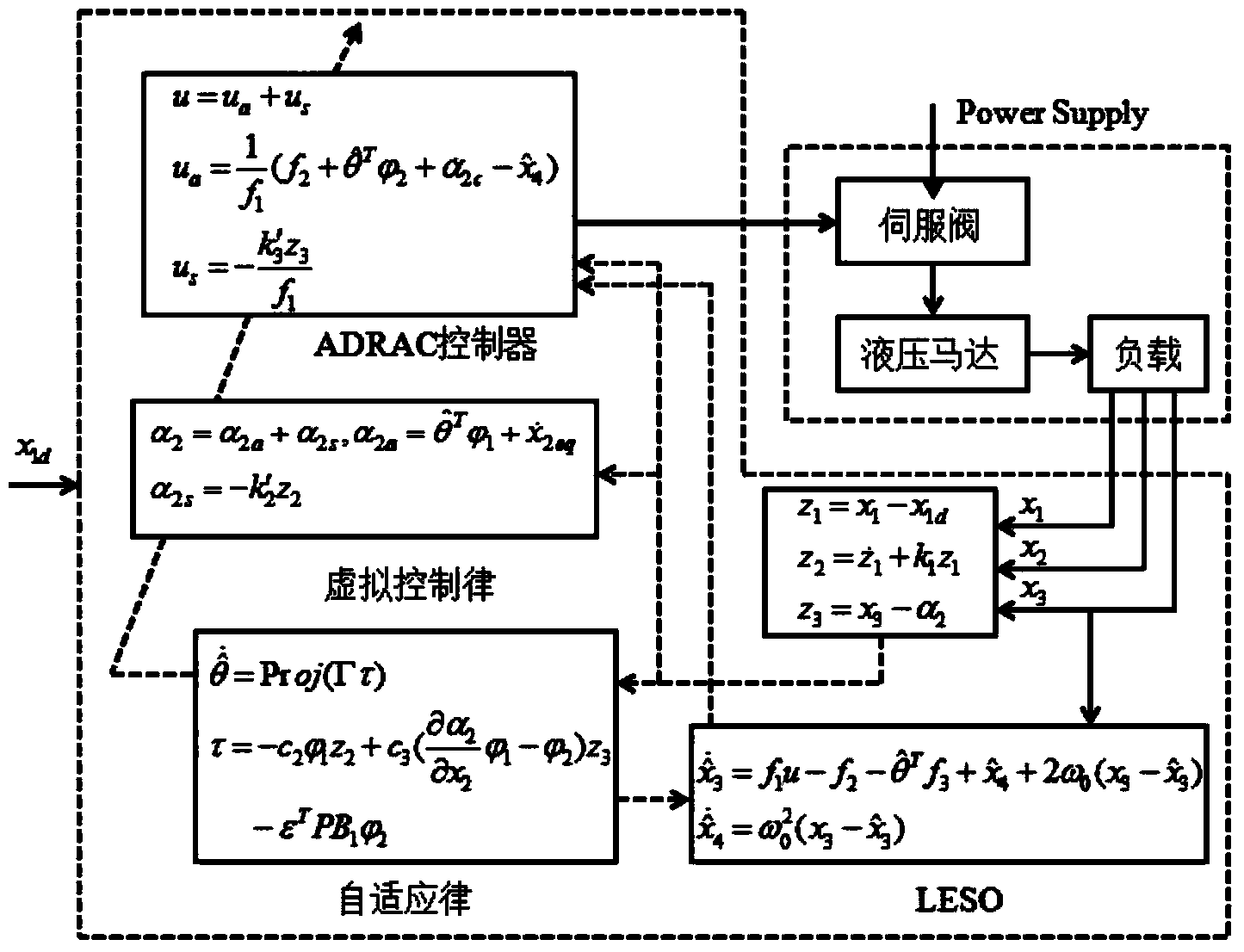

Method used

Image

Examples

Embodiment

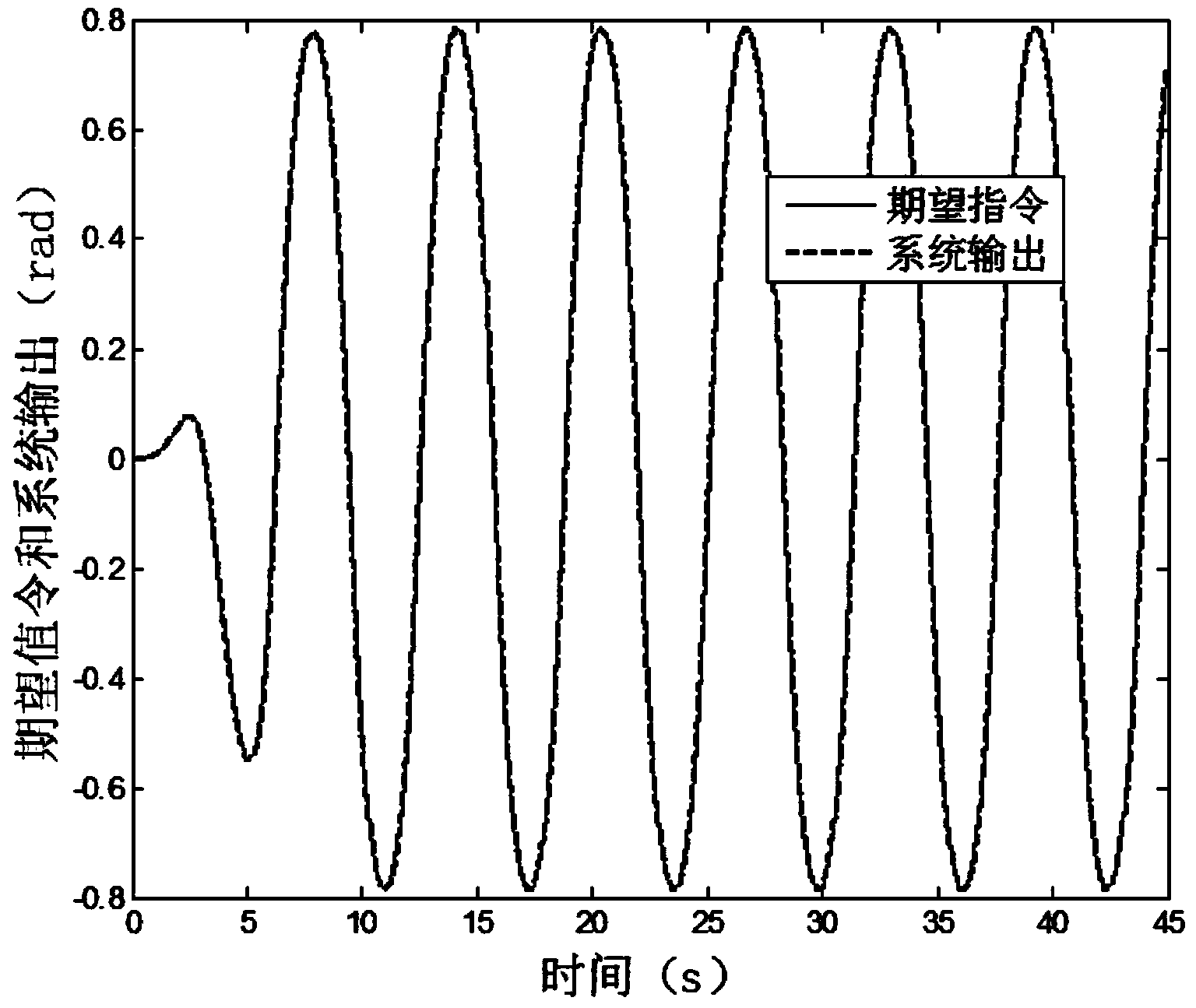

[0194] In order to assess the performance of the designed controller, the following parameters are taken in the simulation to model the hydraulic motor position servo system:

[0195] Load moment of inertia m=40kg·m2 , Motor displacement A=2×10 -4 m 3 / rad, viscous friction coefficient B=80N m s / rad, oil supply pressure P s =7MP a , return oil pressure P r =0, oil elastic modulus β e =2×10 8 P a , the total control volume V of the two chambers of the motor t =2×10 -3 m 3 , leakage coefficient C t =9×10 -12 m 3 / s / P a , total flow gain Coulomb friction amplitude A f =10N·m, shape function Pressure dynamic modeling error Q(t)=1×10 -4 m 3 rad / s.

[0196] The desired instruction for a given system is x 1d =sin(t)[1-exp(-0.01t 3 )] (rad). Take the following controller for comparison:

[0197] Active Disturbance Rejection Adaptive (ADRAC) Controller:

[0198] Get controller parameters: k 1 = 500 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com