Cable Connector Assembly

A technology of cable connectors and components, which is applied in the direction of connection, parts of connection devices, protective grounding/shielding devices of connection parts, etc., which can solve the problems of shielding shells, complicated installation ring structures, unsuitable installation methods, and high production costs. problems, achieve good high-frequency performance and heat dissipation effect, save production cost, and avoid the effect of welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

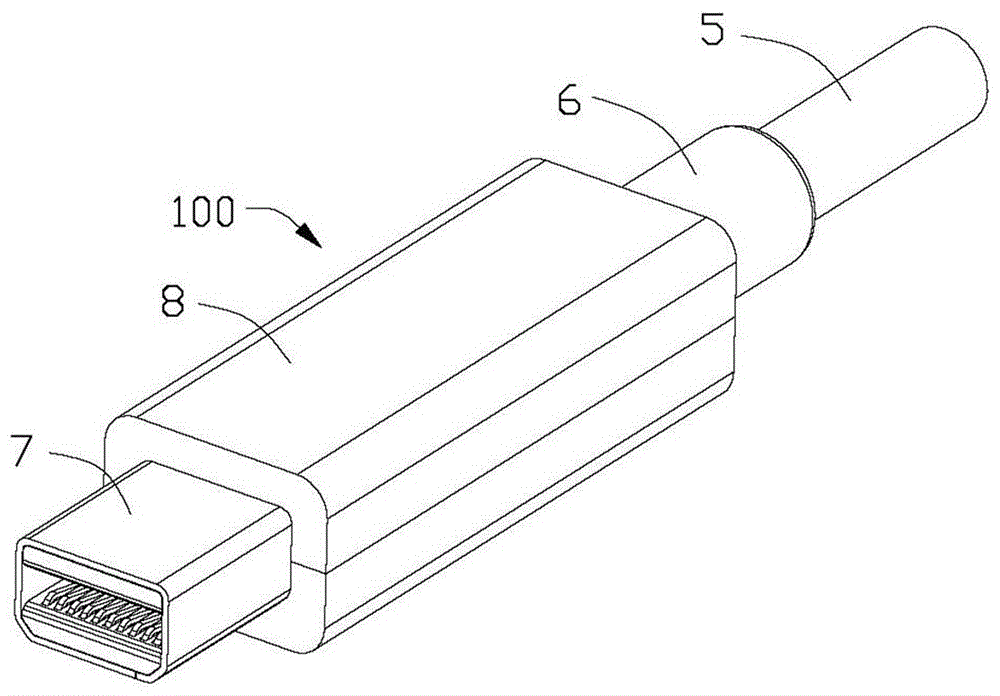

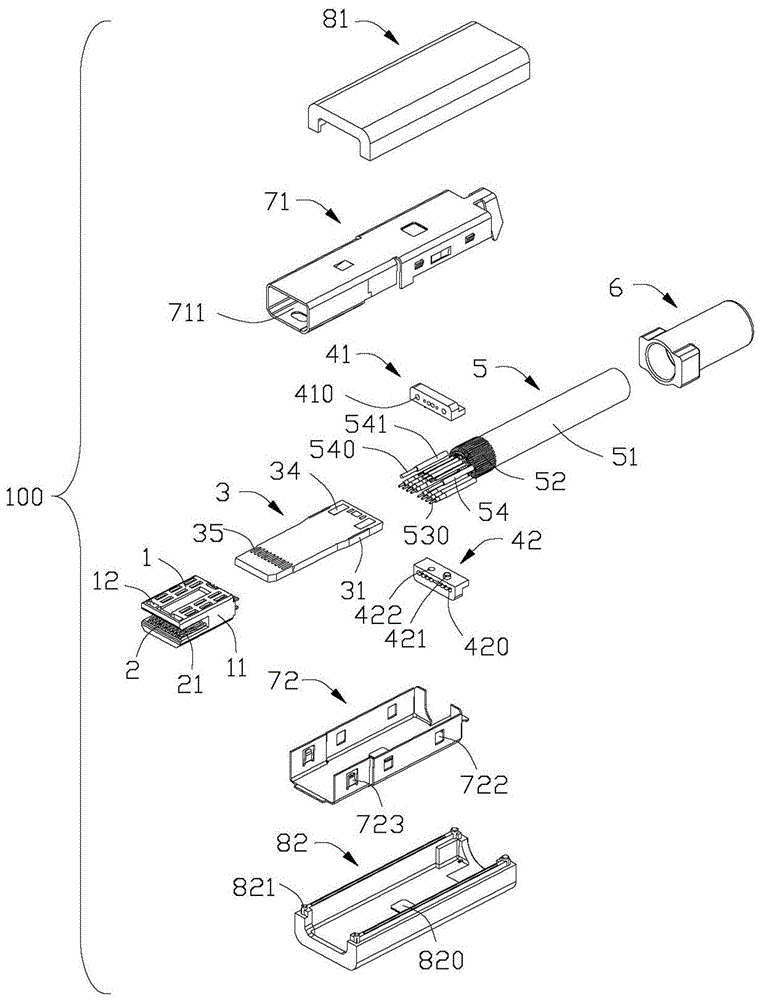

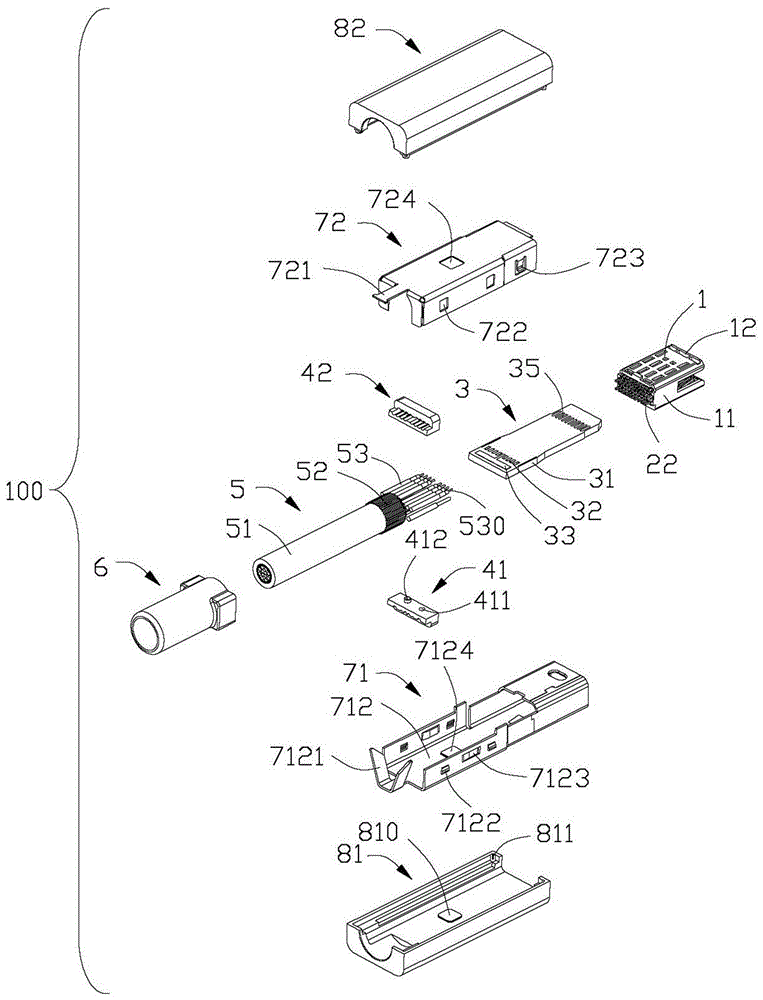

[0017] Please refer to Figure 1 to Figure 5 As shown, the cable connector assembly 100 of the present invention includes an insulating body 1, a plurality of conductive terminals 2 accommodated in the insulating body 1, a printed circuit board 3 electrically connected to the plurality of conductive terminals 2, a covering insulating body 1 and a printed circuit board. The metal shell 7 of the board 3, the insulating shell 8 covering the metal shell 7, the cable 5 electrically connected to the printed circuit board 3, the cable management block 4 installed on the front end of the cable 5, and the cable 5 covered The stress relief part 6 on the outer surface.

[0018] The insulating housing 1 includes a base 11 and a pair of tongues 12 extending forward from the front surface of the base 11 . The pair of tongues 12 are formed facing each other. The conductive terminals 2 include signal terminals and ground terminals with the same structure, and the conductive terminals 2 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com