A constant current drive circuit

A technology of constant current drive and circuit, applied in the direction of lamp circuit layout, electric light source, electrical components, etc., can solve problems such as dark brightness and poor display effect, achieve the goals of shortening the difference, optimizing display effect, and improving user experience Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

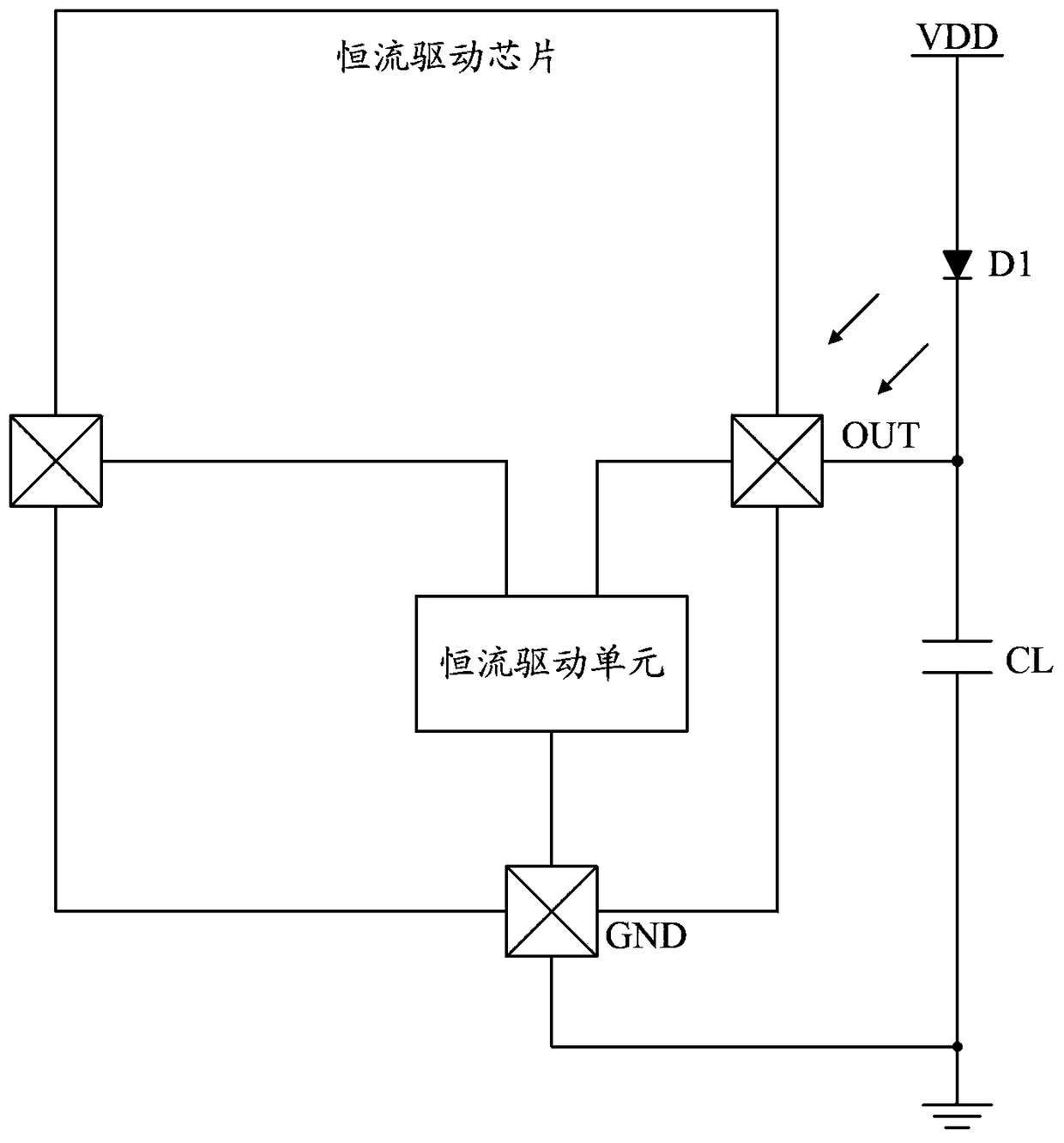

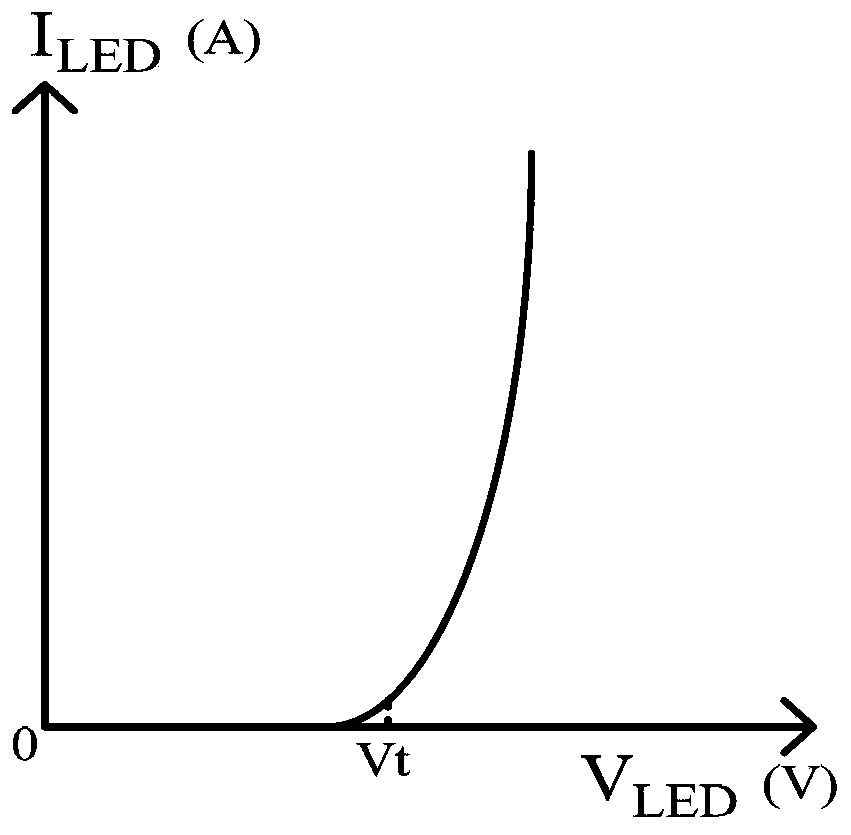

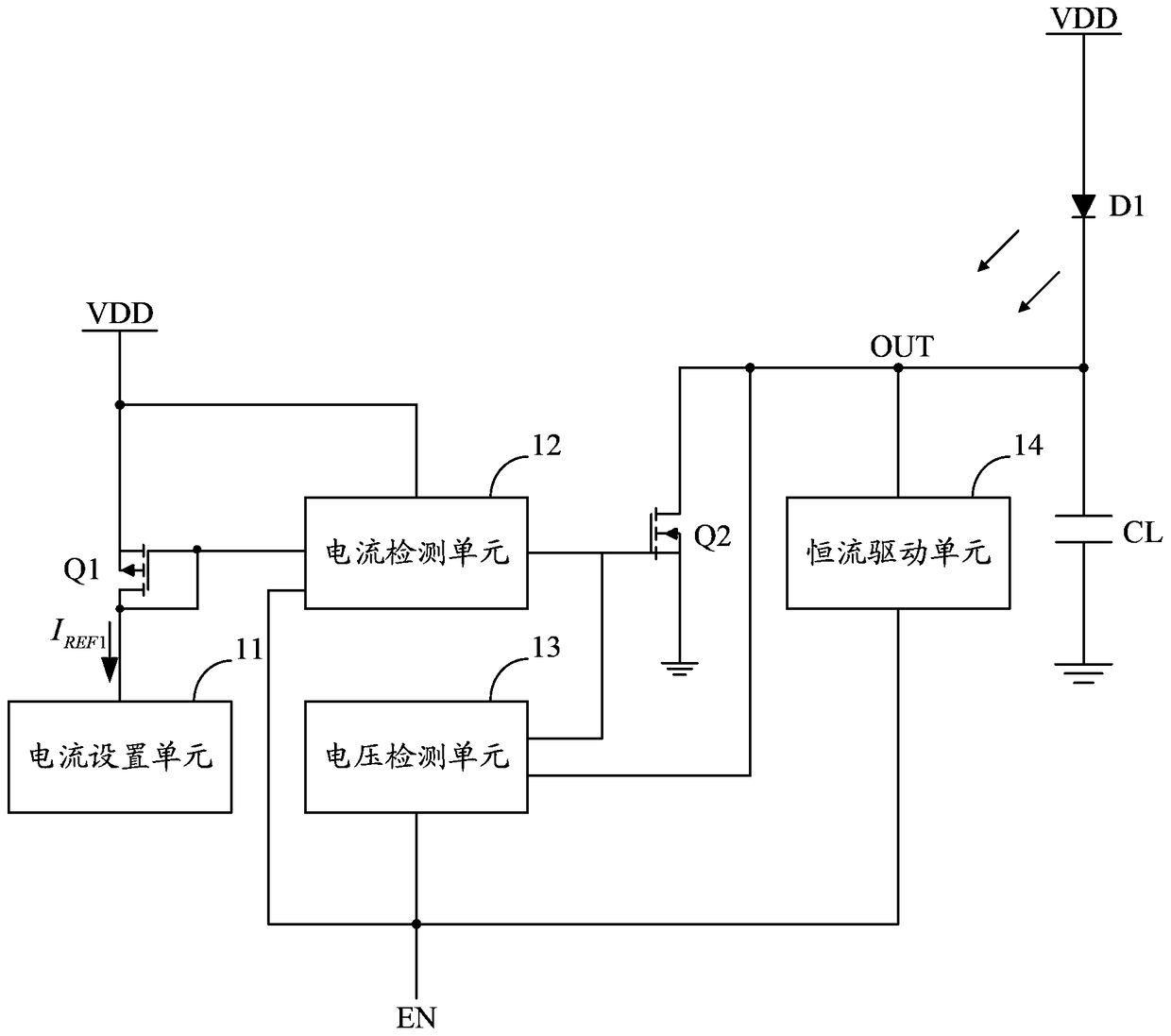

[0030] Embodiment 1 of the present invention proposes a constant current drive circuit, such as figure 2 As shown, for ease of description, only the part related to Embodiment 1 of the present invention is shown.

[0031] In detail, the constant current drive circuit proposed in Embodiment 1 of the present invention includes a power switch tube Q1 and a power switch tube Q2, the high end of the power switch tube Q1 is connected to the direct current VDD, and the driving end of the power switch tube Q1 is connected to the low voltage of the power switch tube Q1. end, the low end of the power switch tube Q2 is grounded; the constant current drive circuit also includes: a constant current drive unit 14, the input end of the constant current drive unit 14 is connected to the enable control signal EN, and the output terminal OUT of the constant current drive unit 14 serves as The output current port of the constant current drive circuit is connected to the drive terminal of the lo...

Embodiment 2

[0037] Embodiment 2 of the present invention proposes a constant current drive circuit, such as Figure 4 As shown, for ease of description, only the part related to Embodiment 2 of the present invention is shown.

[0038] In order to reduce the power consumption of the constant current drive circuit, it is expected that the current detection unit 12 will be turned off after the load is fully turned on. For this reason, different from the first embodiment, the constant current drive circuit provided by the second embodiment may also include: delayed shutdown Unit 15, the second input terminal of the current detection unit 12 is connected to the enabling control signal EN through the delay closing unit 15, the input terminal of the delay closing unit 15 is connected to the enabling control signal EN, and the output terminal of the delay closing unit 15 The second input end of the current detection unit 12 is connected, and is used for reducing the voltage value of the output cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com