Formaldehyde free binding composition, for mineral fibres

A bonding composition, the technology of the composition, applied in the directions such as glucan adhesives, coatings, glass manufacturing equipment, etc., can solve the problems of unfavorable industrial production and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

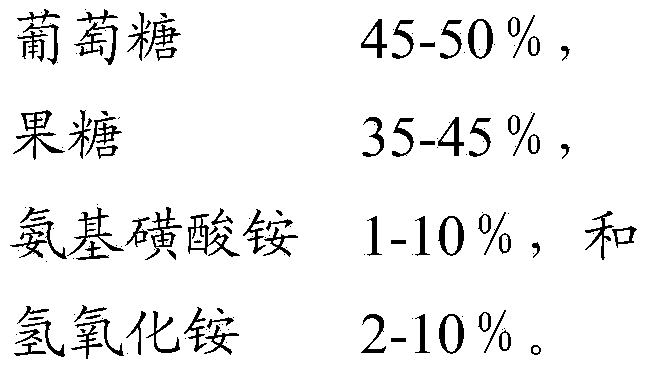

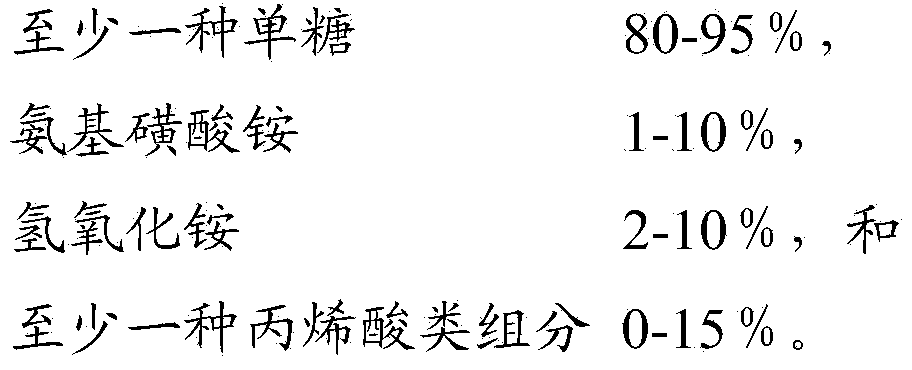

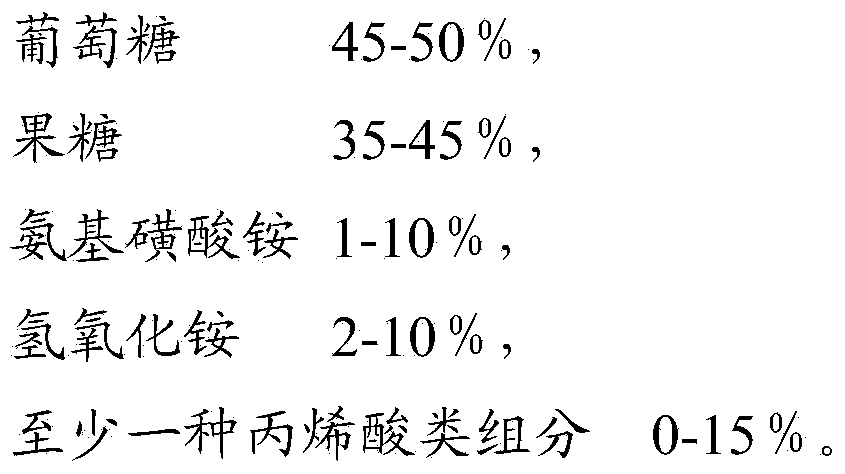

Method used

Image

Examples

Embodiment 1

[0078] Example 1: Polymerization rate of the composition of the invention as binder in the preparation of fibrous material.

[0079] The rate of polymerization of the following compositions of the invention was determined by measuring the so-called "gel time". Gel time is a known experimental variable used by those skilled in the art enabling the measurement of the rate of polymerization of aqueous bonding compositions. Said technique consists, inter alia, of pouring a quantity of an aqueous bonding composition on a thermostatically controlled heated surface (usually a plate) and measuring the time required to form the first filaments of said composition.

[0080] In this example, the composition of the present invention was determined by pouring a quantitative amount (in milliliters) of the aqueous bonding composition on a hot plate at a temperature of about 150° C. and measuring the time taken to form the first filament using a spatula. gel time.

[0081] The gel time is a...

Embodiment 2

[0099] Embodiment 2 (comparative example)

[0100] The experiment for calculating the gel time as in Example 1 was carried out with ammonium sulfate as polymerization / crosslinking agent. The results are summarized in Table 2.

[0101] Table 2: Gel time values for compositions in Example 1 using ammonium sulfate (3%) instead of ammonium sulfamate (3%)

[0102] combination

Deposition volume and plate temperature

Polymerization time (gel time)

A1

2ml(150℃)

34 seconds

B1

2ml(150℃)

35 seconds

C1

2ml(150℃)

30 seconds

[0103] A1-C1: Compositions corresponding to compositions A-C of Example 1, wherein ammonium sulfamate (3%) was replaced by ammonium sulfate (3%).

[0104] It can be easily deduced from Tables 1 and 2 above that the composition of the present invention makes it possible to obtain significantly higher rates of polymerization (for the same amount of polymerization / crosslinking agent used), which r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com