Coating method and coating device

A coating method and a technology of a coating device, which are applied in the direction of a device for coating liquid on a surface, a coating, and a pre-treated surface, etc., can solve problems such as uneven layers of objects to be coated, avoid resource waste, facilitate popularization and application, The effect of convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

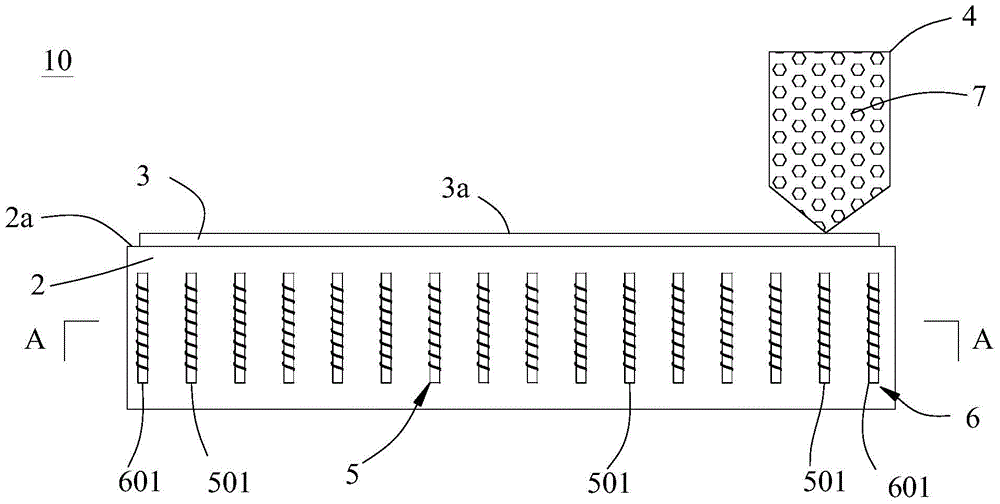

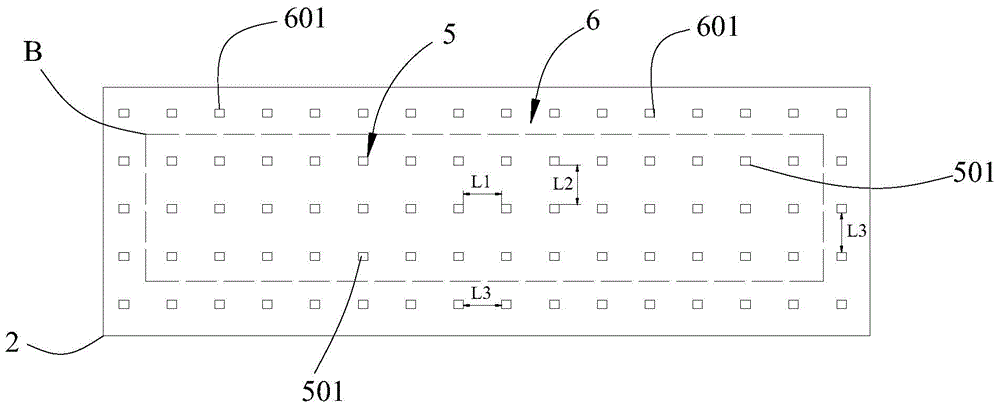

[0028] figure 1 and 2 Shown is a coating device 10 according to the invention, which is mainly used for coating a substrate 7 onto a carrier 3 and promoting a uniform distribution of the substrate layer formed on the carrier 3 . The coating device 10 includes a base 2 and a bearing surface 2 a formed on the top end of the base 2 . The carrying surface 2 a is used to place the carrier 3 , and it can completely coincide with the contact surface of the carrier 3 . In a preferred embodiment, the carrying surface 2a is a plane for placing a glass substrate (ie, the carrier 3 ).

[0029] According to the present invention, the coating device 10 also includes a coating mechanism 4 capable of coating the object to be coated 7 mixed with magnetic particles on the surface to be coated 3a of the carrier 3, and an alternating magnetic field source arranged below the carrying surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com