Primer-free coating method of self-adhesive acrylate emulsion and coating system implementing primer-free coating method

A technology of acrylate and coating method, which is applied in the direction of surface coating liquid device, coating, pretreatment surface, etc., which can solve the problems of inability to meet product testing requirements, easy fatigue, missed inspection costs, etc., and achieve heat sealing Excellent performance and peel strength, increased productivity, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

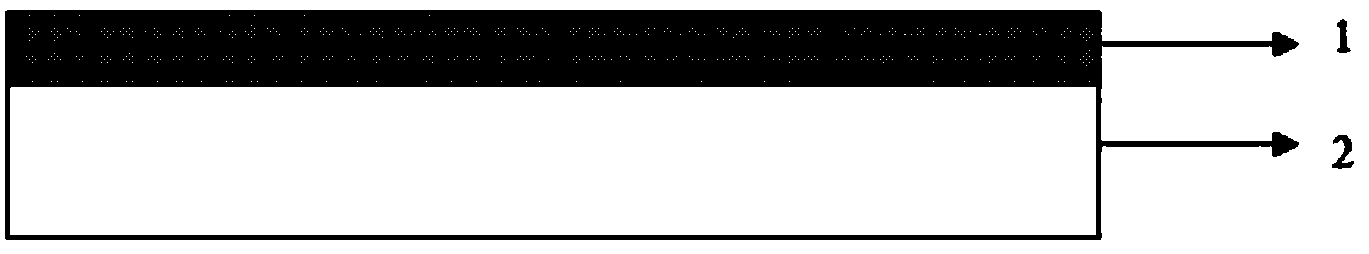

Image

Examples

Embodiment 1

[0032] 1. Unwinding process: under a constant unwinding tension of 35N, the BOPP reel-shaped film with a thickness of 19μm is flatly unrolled into a continuous and stable operation;

[0033] 2. Plasma treatment process: the surface tension of the base film after treatment reaches 75dyn / cm;

[0034] 3. Top coating process: the plasma-treated film enters the top coating process, using reverse gravure coating, through the cooperation of the coating roller and the scraper, the self-adhesive AC emulsion of the top coating is transferred from the trough to the film surface through the coating roller , where the coating process is transferred to the film surface by the coating roller and the coating is controlled at 0.8g / m 2 , the coating thickness is 0.5 μm, and the tension of the coating film is controlled at 30N; wherein the wax emulsion and silica anti-adhesive agent are added to the self-adhesive AC emulsion of the top coating; the self-adhesive AC emulsion is combined with the ...

Embodiment 2

[0040] 1. Unwinding process: Under the constant unwinding tension of 40N, the BOPET reel-shaped film with a thickness of 12μm is flatly unrolled into a continuous and stable operation;

[0041] 2. Plasma treatment process: the surface tension of the base film after treatment reaches 78dyn / cm;

[0042] 3. Top coating process: the plasma-treated film enters the top coating process, using reverse gravure coating, through the cooperation of the coating roller and the scraper, the self-adhesive AC emulsion of the top coating is transferred from the trough to the film surface through the coating roller , wherein the coating process is transferred to the film surface by the coating roller and the coating is controlled at 1.0g / m 2 , the coating thickness is 0.6μm, and the tension of the coating film is controlled at 50N; among them, wax emulsion and silica anti-adhesive agent are added to the self-adhesive AC emulsion of the top coating; among them, the self-adhesive AC emulsion and w...

Embodiment 3

[0048] 1. Unwinding process: Under a constant unwinding tension of 45N, the BOPA roll-shaped film with a thickness of 28μm is flatly unrolled into a continuous and stable operation;

[0049] 2. Plasma treatment process: the surface tension of the base film after treatment reaches 80dyn / cm;

[0050] 3. Top coating process: the plasma-treated film enters the top coating process, using reverse gravure coating, through the cooperation of the coating roller and the scraper, the self-adhesive AC emulsion of the top coating is transferred from the trough to the film surface through the coating roller , where the coating process is transferred to the film surface by the coating roller and the coating is controlled at 1.4 / m 2 , the coating thickness is 0.8μm, and the tension of the coating film is controlled at 60N; among them, wax emulsion and silica anti-adhesive agent are added to the top coat AC emulsion; among them, self-adhesive self-adhesive AC emulsion and wax emulsion, silica ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com