Flip thermoforming machine

A molding machine and reversing wheel technology, applied in the field of reversing thermoforming machines, can solve the problems of floating light polymer microbeads, uneven specific gravity of silicone products, poor appearance, elasticity and feel, etc., to achieve simple structure and improve product quality. The effect of high quality and low cost of renovation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

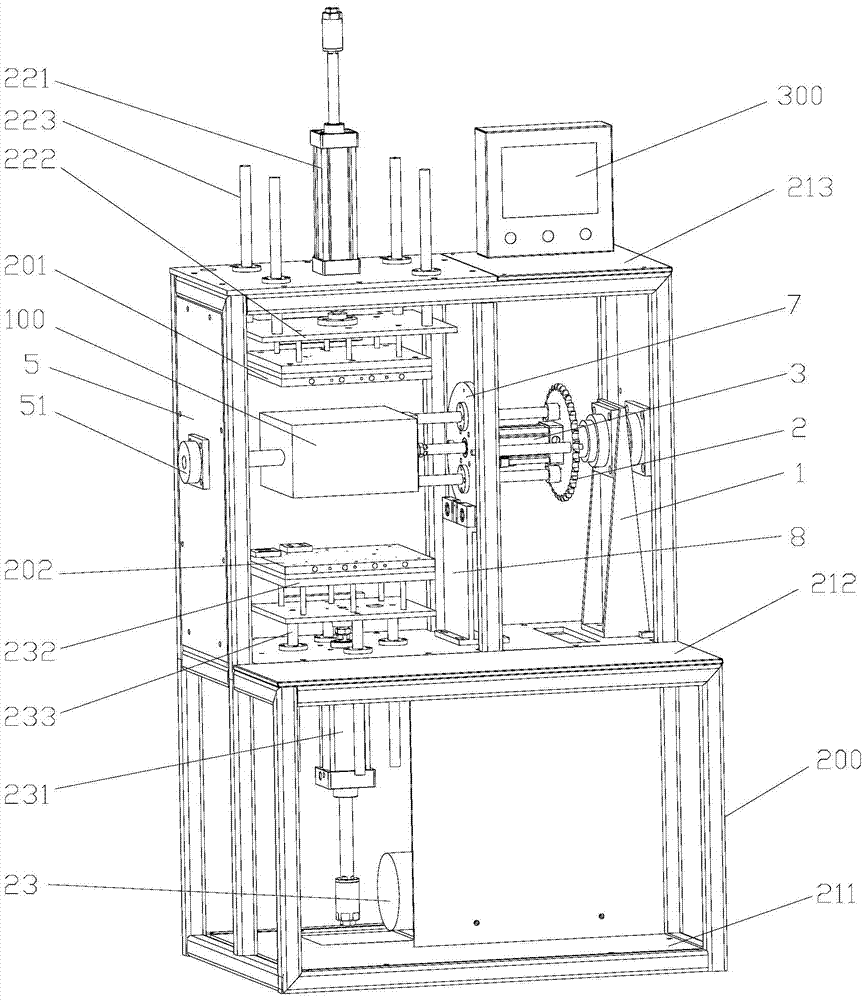

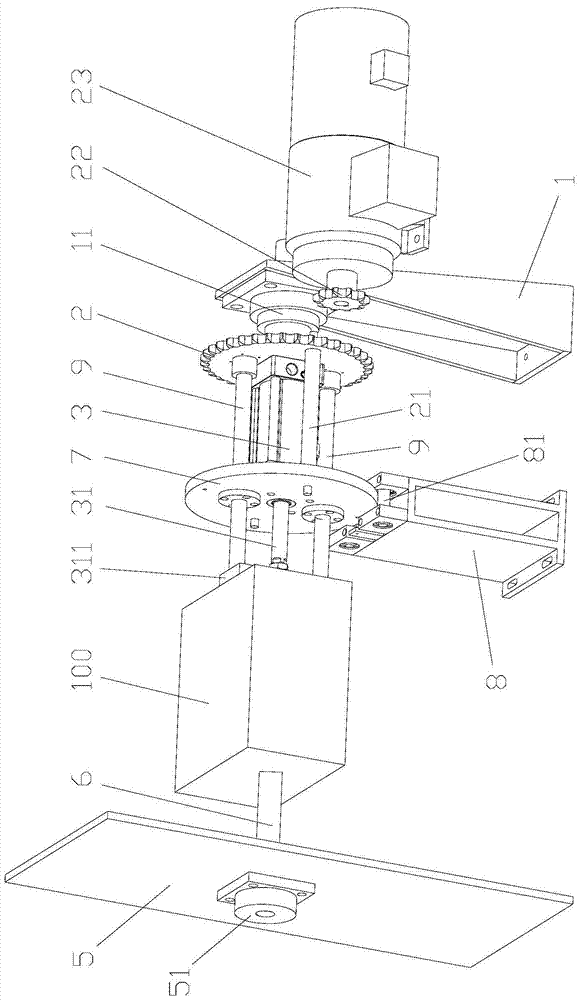

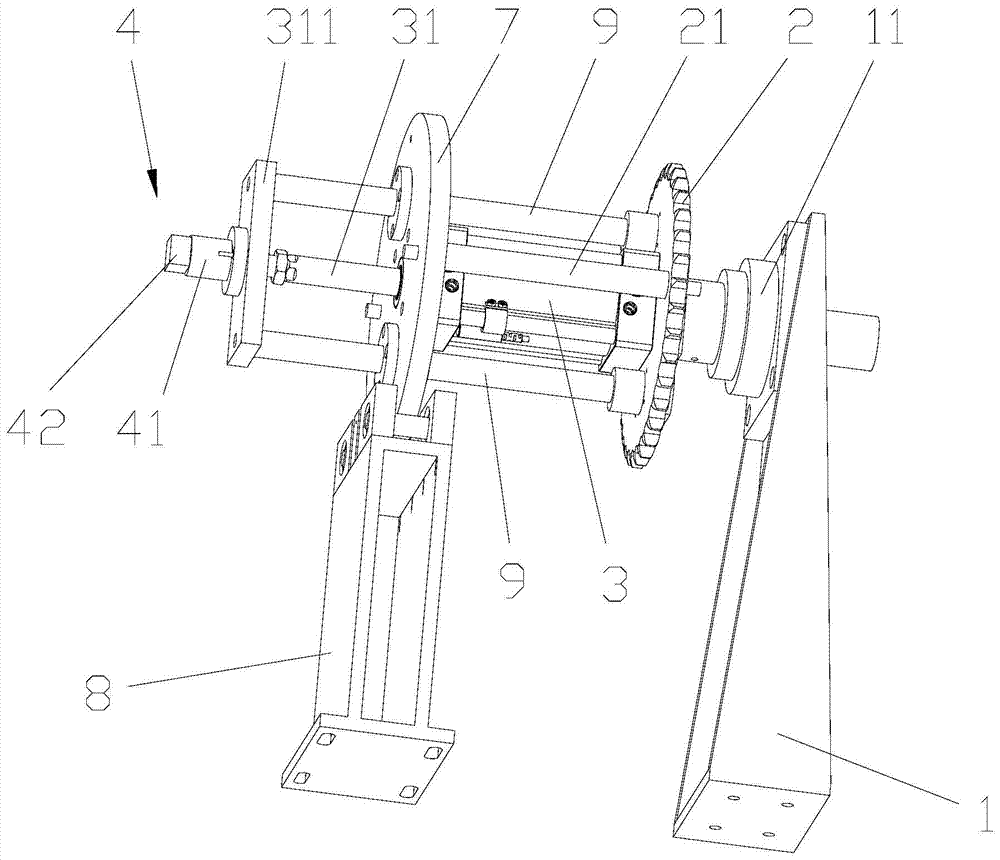

[0026] see Figure 1 to Figure 3 , a reversing thermocompression forming machine, including a frame 200, an upper die heating plate 201 and a lower die heating plate 202 arranged at intervals up and down on the frame 200, and arranged on the frame 200 to drive the upper die heating plate 201 to lift The upper mold lifting mechanism, the lower mold lifting mechanism that is arranged on the frame 200 to drive the lower mold heating plate 202 to lift, the hot pressing mold 100 that is arranged in the middle of the upper mold heating plate 201 and the lower mold heating plate 202, and the frame 200 A clamping and turning device for clamping and turning over the hot pressing mold 100 is also provided on the top. Wherein, the frame 200 is a double-layer frame structure, including a bottom plate 211 , an operating table 212 in the middle, and a top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com