High-brightness quartz lamp pendant

A crystal lamp, high-brightness technology, used in layered products, chemical instruments and methods, metal layered products, etc., can solve the problems of no metal color, low brightness, no crystal clear, etc., to achieve a crystal clear appearance and high brightness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

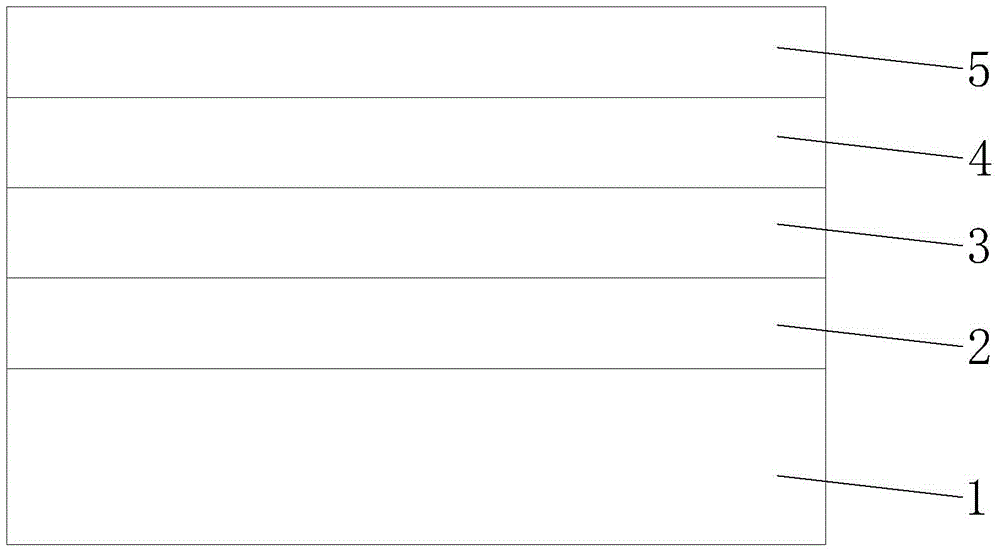

[0014] As shown in the figure, a high-brightness crystal lamp pendant includes a pendant body 1, and the outer surface of the pendant body 1 is sequentially provided with a bottom titanium oxide film layer 2, a chrome film layer 3, and a titanium film layer 4. , and the top titanium oxide film layer 5 .

[0015] Further, the pendant body 1 is made of glass or transparent plastic. Before the film layer is formed on the outer surface of the pendant body 1, the pendant body 1 is ultrasonically cleaned in acetone for 10 minutes, then ultrasonically cleaned with ethanol for 10 minutes, then ultrasonically cleaned in deionized water for 10 minutes, and finally enters the magnetron sputtering process. The system performs coating treatment.

[0016] Still further, the thickness of the underlying titanium oxide thin film layer 2 is 10-20 mm. It adopts the magnetron sputtering coating process, uses oxygen as the reaction gas, argon as the protective gas, and sputters the ceramic titan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap