Polymer composition with metallic luster

A metal luster and polymer technology, applied in the field of polymer composition, can solve problems such as high production cost, inaccurate size, and defects in car teeth, and achieve the effect of beautiful appearance and similar color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

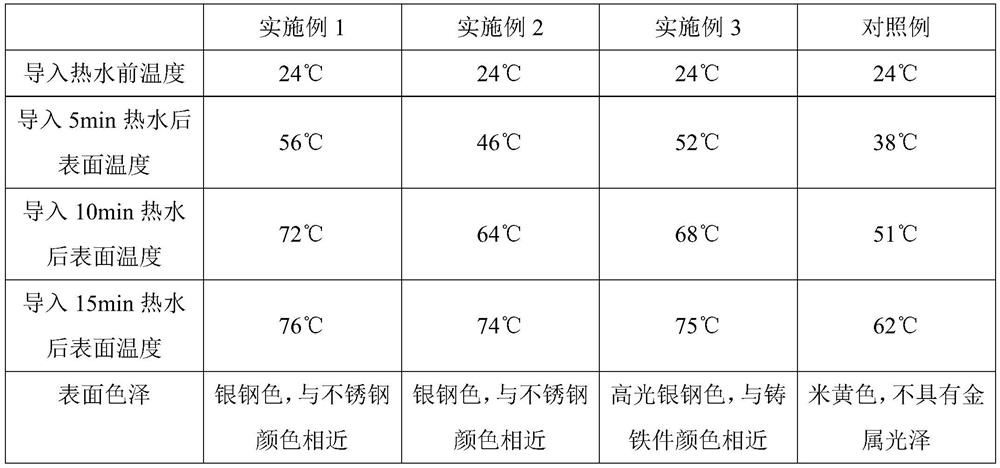

Examples

preparation example Construction

[0019] The preparation method of embodiment 1-3 aluminum powder of the present invention is as follows:

[0020] The aluminum ingot is melted and sprayed into powder or ground with kerosene and stearic acid in a ball mill with aluminum foil, rinsed with kerosene, blotted dry, and then mixed with an appropriate amount of No. 200 coal coke solvent.

[0021] Solvent Yellow 114 of Examples 1-3 of the present invention was prepared by the 2-methyl-3-hydroxyquinoline method.

[0022] The iron oxide of the embodiment of the present invention 1-3 is micaceous iron oxide, and preparation method is as follows:

[0023] Mica hematite method After the mica hematite ore is selected, it is ground into concentrate powder by a wet ball mill, dehydrated, dried, cooled, crushed to 325 mesh, and sieved to make mica iron oxide.

[0024] The PC resin of Example 1 of the present invention is bisphenol A polycarbonate.

[0025] The ABS resin of Example 2-3 of the present invention is polymerized f...

Embodiment 1

[0031] The polymer composition with metallic luster in Example 1 of the present invention consists of the following raw materials in parts by weight: 25,000 parts by weight of PC resin, 550 parts by weight of aluminum powder, 0.1 part by weight of solvent yellow 114, and 2 parts by weight of iron oxide.

[0032] The finished product of Example 1 of the present invention is silver-steel-colored, which is similar to the color of stainless steel.

Embodiment 2

[0034] The polymer composition with metallic luster in Example 2 of the present invention consists of the following raw materials in parts by weight: 25,000 parts by weight of ABS resin, 150 parts by weight of aluminum powder, 0.8 parts by weight of solvent yellow 114, and 10 parts by weight of iron oxide.

[0035] The finished product of Example 2 of the present invention is silver-steel-colored, which is similar to the color of stainless steel.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap