Heavy truck self-power-generation motor vehicle

An electric power vehicle, spontaneous technology, applied in vehicle parts, auxiliary drive devices, control devices, etc., can solve the problems of restricted mileage, troublesome replacement, large spring pressure of shock absorber, etc., to achieve regeneration and utilization, overall weight Small, fast-amplitude effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

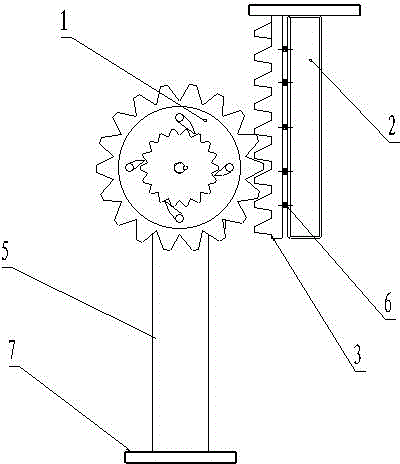

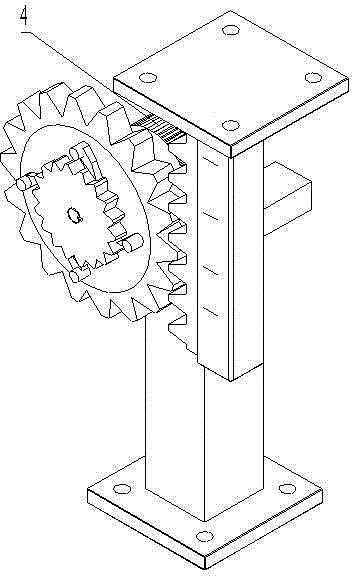

[0007] Refer to attached figure 1 , 2 , the present embodiment mainly includes the vehicle body underframe 7 and the shock absorbing spring near the wheel, the bottom of the shock absorbing spring is horizontally provided with a board 8, and the vertical board 8 is arranged in parallel with the rack connecting seat 2 and the rack 1 downwards. A compression spring 6 is added between the rack connection seat 2 and the rack 1; a throwing wheel 1 is set in mesh with the rack 3, and the shaft of the throwing wheel 1 is connected to the motor 4, and the base 5 of the motor 4 is fixedly arranged on the frame plate 7, and the motor 4 Electricity is fed into the battery through wires.

[0008] As the vehicle travels on sandy ground, potholes, or mountainous terrain, the shock absorbing spring near the wheel has a large, fast and large amplitude during driving, and the strap 8 connected to the shock absorbing spring drives the rack 3 up and down. Movement, the spinner meshed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com