Proportional Control System and Proportional Control Method of Non-contact Steering Limit

A proportional control and non-contact technology, applied in the direction of automatic steering control components, steering mechanisms, steering rods, etc., can solve the problems of large size, easy failure of the limit rubber block, and large impact at the end position of the steering, so as to achieve easy structural modification , long service life and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

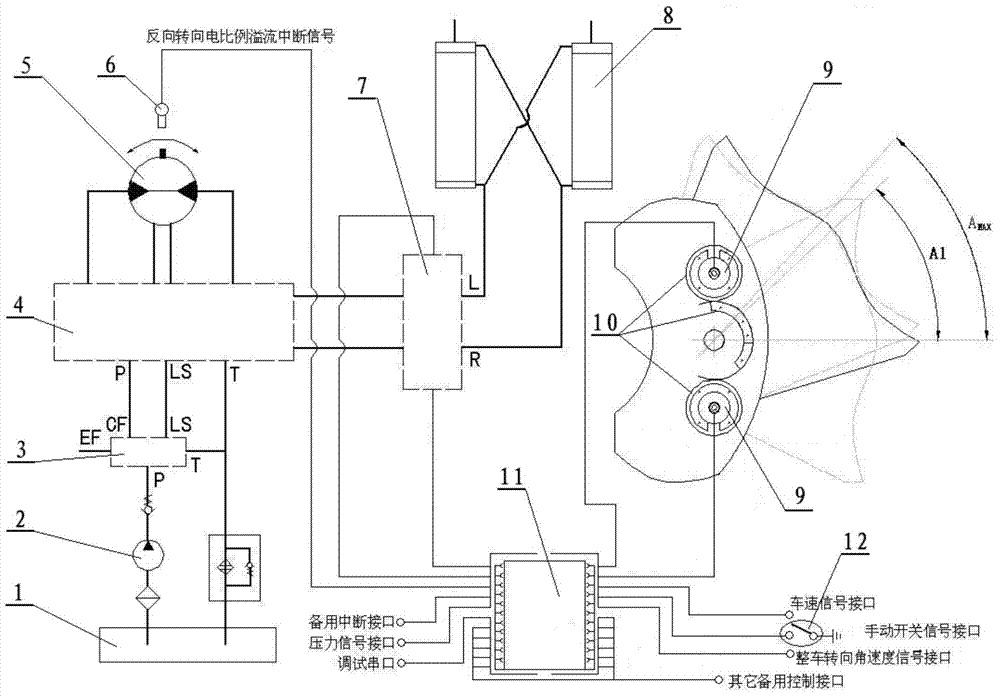

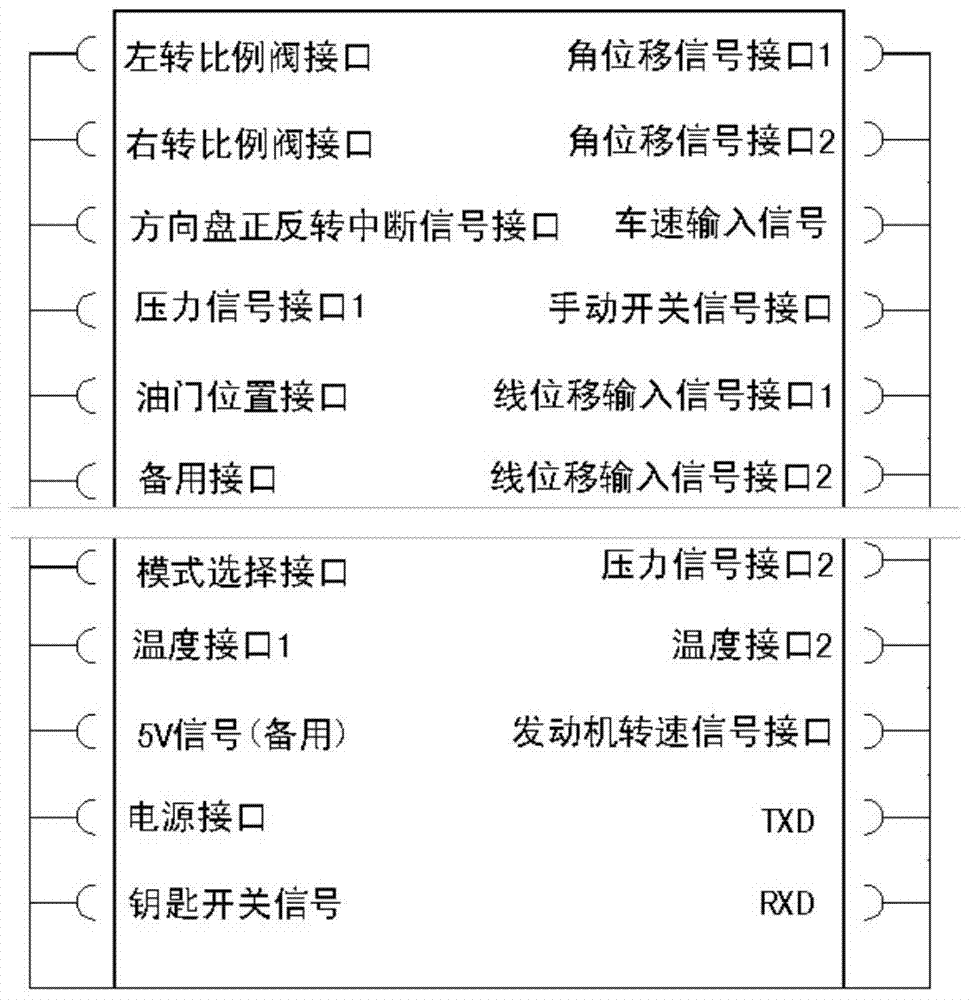

[0060] Such as figure 1 , 2 As shown, a non-contact steering limit proportional control system based on displacement sensing technology and quantitative proportional relief hydraulic technology applied to articulated steering vehicles, including hydraulic oil tank 1, quantitative steering pump 2, switch relief valve Module 3, flow amplification valve module 4, steering gear module 5, forward and reverse intention sensor assembly 6, electro-proportional relief valve module 7, steering cylinder 8, angular displacement sensor assembly, controller 11, manual switch 12, and mechanical Type rubber damping buffer device;

[0061] The hydraulic oil tank 1, the quantitative steering pump 2, the switch relief valve module 3, the flow amplifying valve module 4, the steering gear module 5, the electro-proportional relief valve module 7, and the steering cylinder 8 are sequentially connected by hydraulic oil pipes to form hydraulic oil Loop

[0062] The forward and reverse intention sensor as...

Embodiment 2

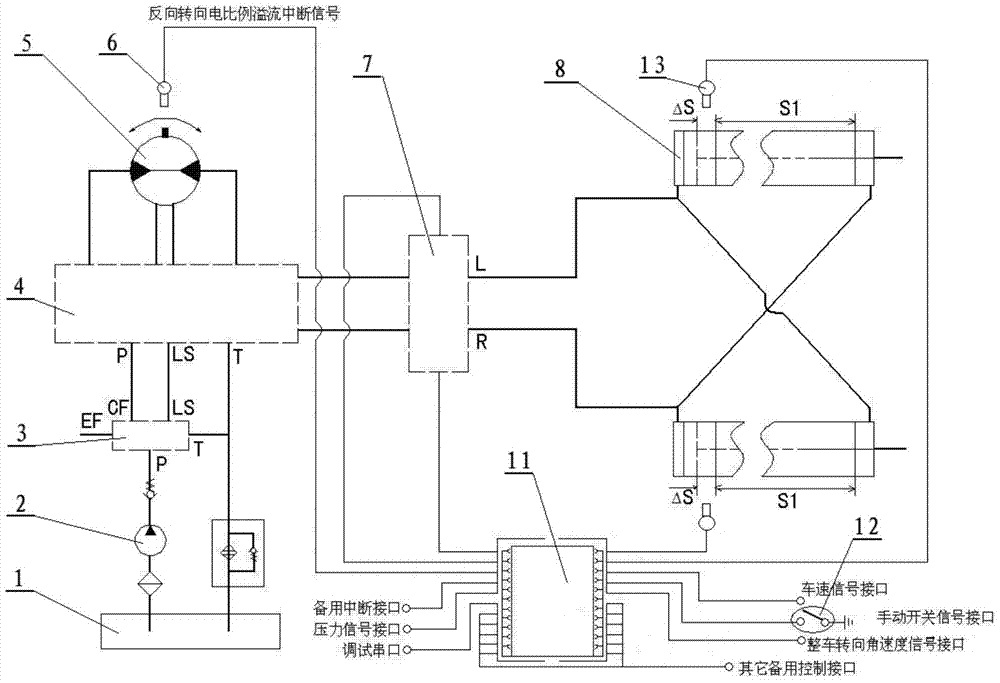

[0073] A non-contact steering limit proportional control system based on displacement sensing technology and quantitative proportional overflow hydraulic technology applied to articulated steering vehicles, including hydraulic oil tank 1, quantitative steering pump 2, switch overflow valve module 3. Flow amplification valve module 4, steering gear module 5, forward and reverse intention sensor assembly 6, electro-proportional relief valve module 7, steering cylinder 8, linear displacement sensor assembly, controller 11, manual switch 12, and mechanical rubber Damping buffer device;

[0074] The hydraulic oil tank 1, the quantitative steering pump 2, the switch relief valve module 3, the flow amplifying valve module 4, the steering gear module 5, the electro-proportional relief valve module 7, and the steering cylinder 8 are sequentially connected by hydraulic oil pipes to form hydraulic oil Loop

[0075] The forward and reverse intention sensor assembly 6 is installed on the steer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com