Flexible order sorting system

A sorting system and order technology, applied in the direction of transportation, packaging, storage devices, etc., can solve problems such as difficult continuous order arrangement, difficult system adjustment and improvement, and easy wear and tear on the surface of cigarettes, so as to improve reliability and stability , Reduce the scale of equipment construction and facilitate standardized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

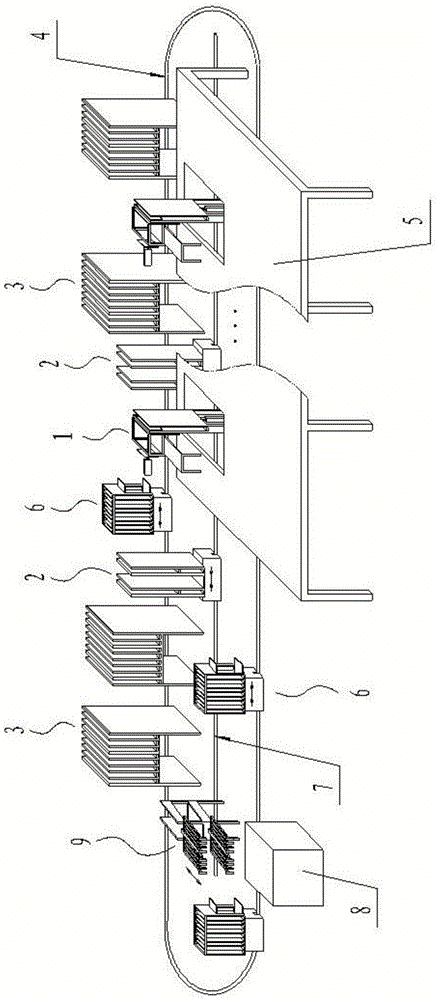

[0034] Such as figure 1 Shown: the present invention is fixed on two pretreatment devices 1 and four storage and sorting devices 3 inside the circular track 4, and the linear track 7 between the pretreatment device 1 and the storage and sorting device 3 is located on the Two mobile replenishment devices 2 on the linear track, three mobile pick-up devices 6 located on the circular track 4, a shipping platform 8 positioned outside the circular track 4, and an unloading device 9 located inside the circular track 4 form. in:

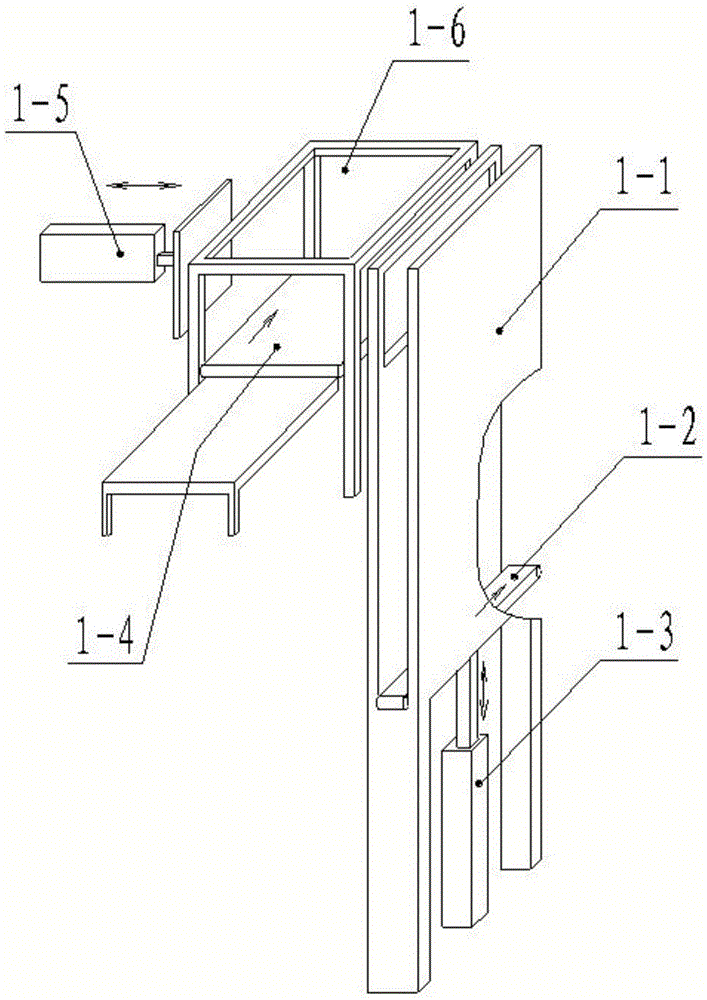

[0035] Pretreatment device 1 such as figure 2 As shown, it consists of a pretreatment bin 1-1 with an inlet (not shown in the figure) on the left side, a first conveying mechanism 1-2 arranged in the pretreatment bin, and a position below the first conveying mechanism. And can drive the elevating mechanism 1-3 that this first c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com