A method and device for quickly realizing anaerobic ammonium oxidation in a biological filter

A technology of anaerobic ammonium oxidation and biofilter, which is applied in the field of sewage treatment, can solve the problems such as the mechanism of pollutant removal in biofilter is not very clear, and achieve the effect of less sludge output, saving operating cost and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

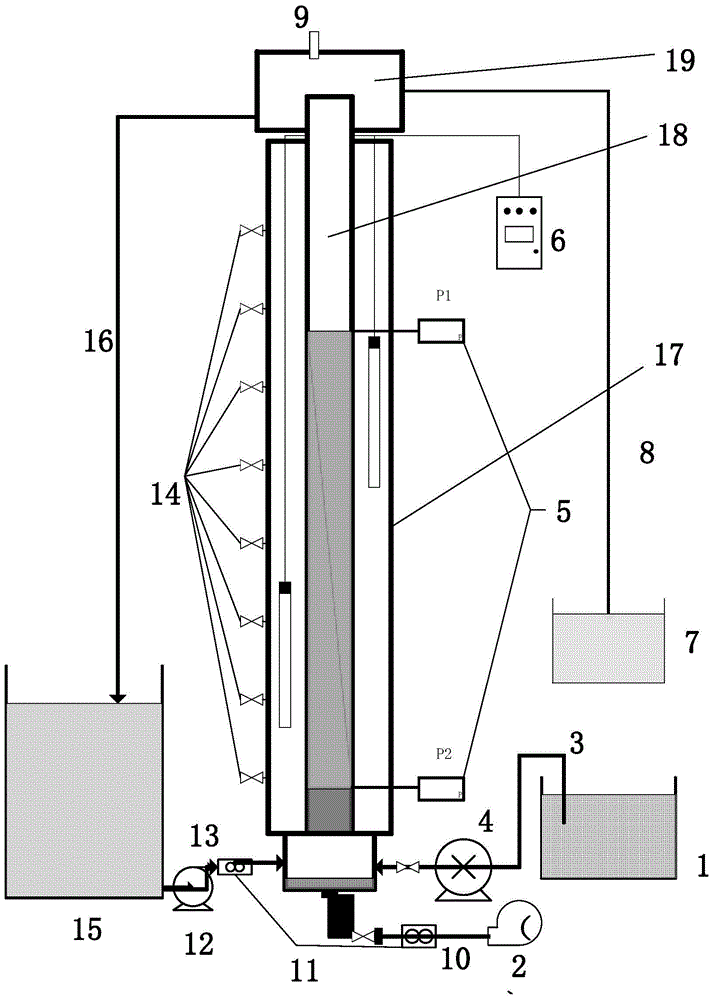

Method used

Image

Examples

Embodiment 1

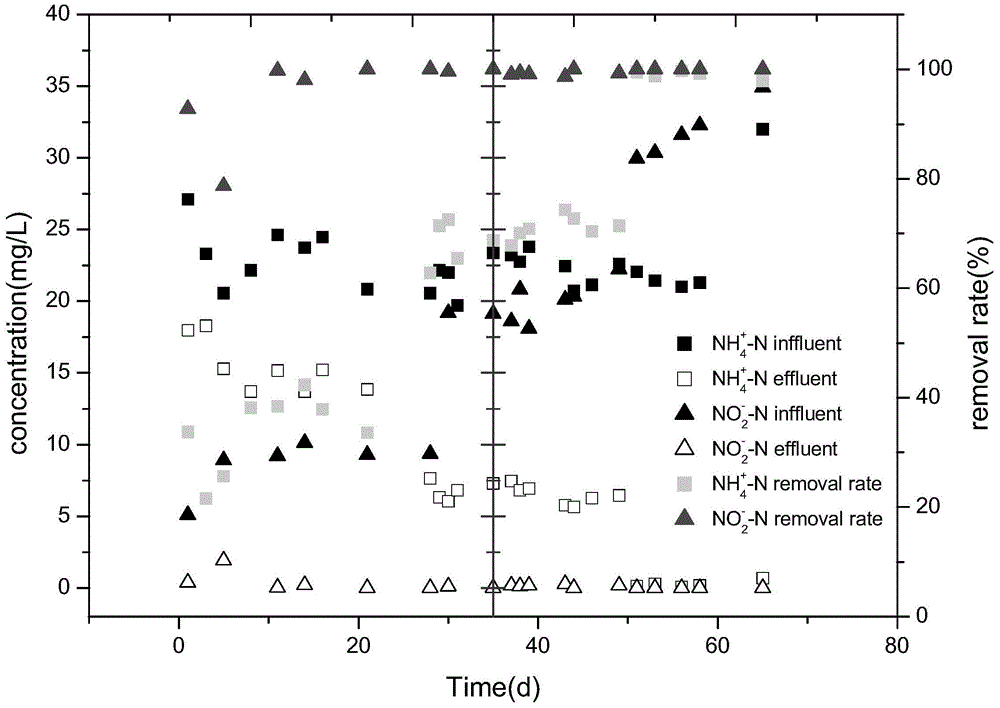

[0033] The secondary effluent (short-cut nitrification-denitrification effluent) after treatment in a family area of a university was used as the experimental object. The effective volume of the anammox biofilter reactor is 16L, with FILTRALITE HR3-6mm (Norway, expanded clay) (preferred) as the filter material, the height of the filter material layer is 1.2m, the height of the supporting layer is 0.2m, continuous water intake, The influent filtration rate is maintained at 0.5m / h, and the influent ammonia nitrogen: nitrite nitrogen mass concentration ratio is maintained at 1:1.32. Concentration is 18mg / L, The concentration is 24mg / L; the reaction temperature is controlled within the range of 30-33°C by a temperature control device.

[0034] 1) Start-up phase: Fill the reactor water bath jacket with water, turn on the temperature control device, and control the temperature at 30-33°C; use a peristaltic pump to pump the mature anammox sludge to be inoculated from the reactor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com