Large-head energy gathering perforating pipe type grouting anchor rod with ribbed steel framework and construction method

A technology of grouting bolts and reinforced steel, which is applied in the installation of bolts, earthwork drilling, infrastructure engineering, etc. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments:

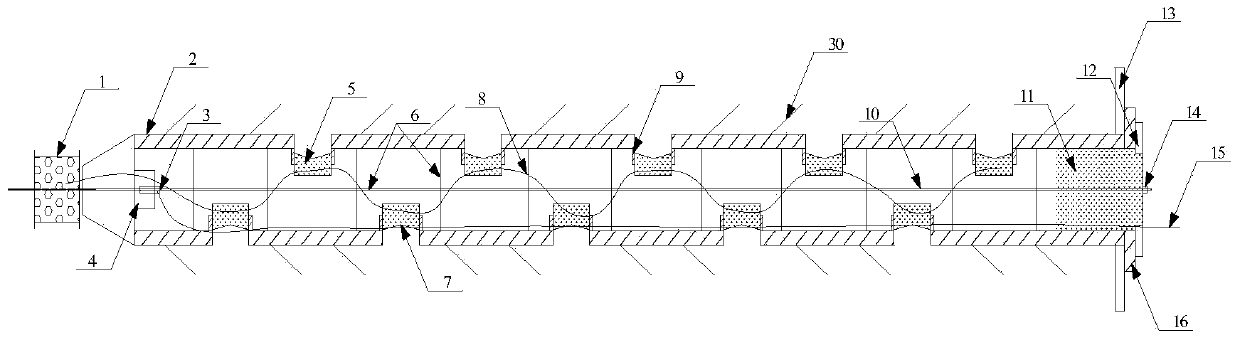

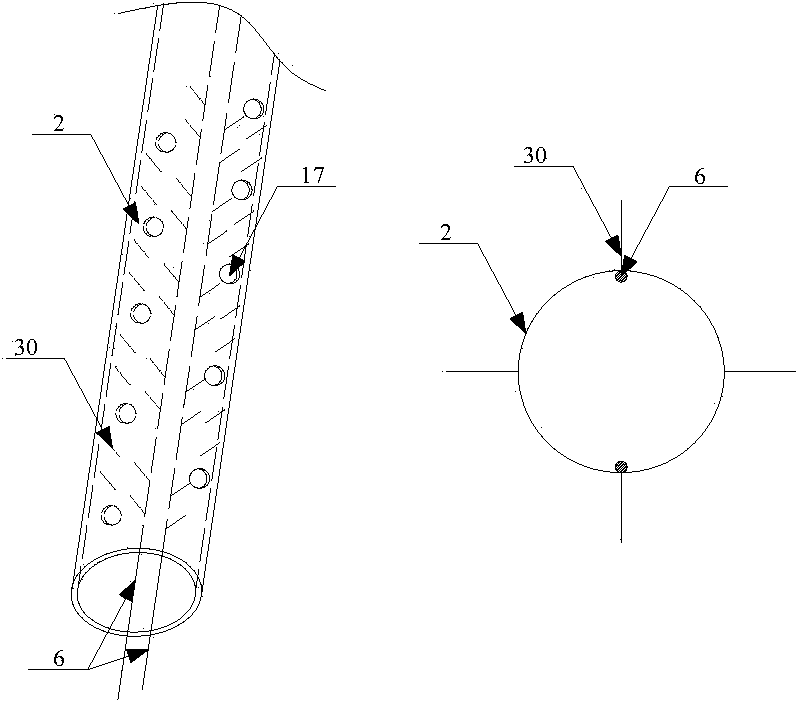

[0035] A large-headed energy-concentrating perforating tubular grouting anchor with a reinforced steel skeleton, comprising a blasting perforation device (1), a tubular grouting anchor body (2), energy-shaping charges (5), and a steel skeleton ( 6) Four main parts;

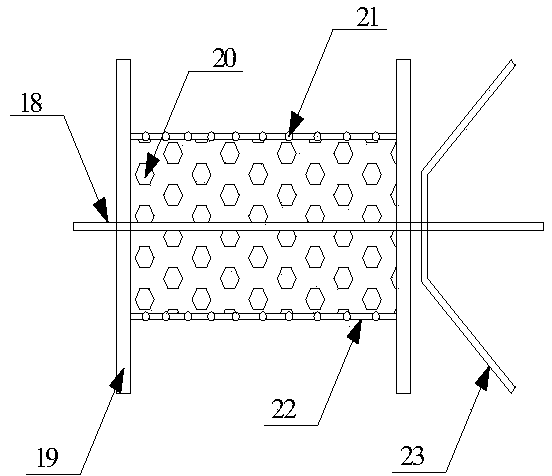

[0036] The blasting perforating device (1) is composed of an axial end iron (19), a fixed rod (18), a radial perforating sleeve (22), a marble (21), a barb (23) and an explosive agent (20) , wherein, the two axial end irons (19) are circular plates with a hole in the middle, which can pass through the fixing rod (18); the radial perforating sleeve (22) is cylindrical and is clamped between the two axial Between the end irons (19), there are detonating medicines (20) inside,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com