High-temperature incinerator combustion hood air curtain protection system

A protection system and combustion hood technology, which is applied in the boiler field, can solve the problems of accelerated aging of furnace arch materials, the impact of combustion hood safety and reliability, etc., and achieve the effect of preventing the radiation surface temperature from being too high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

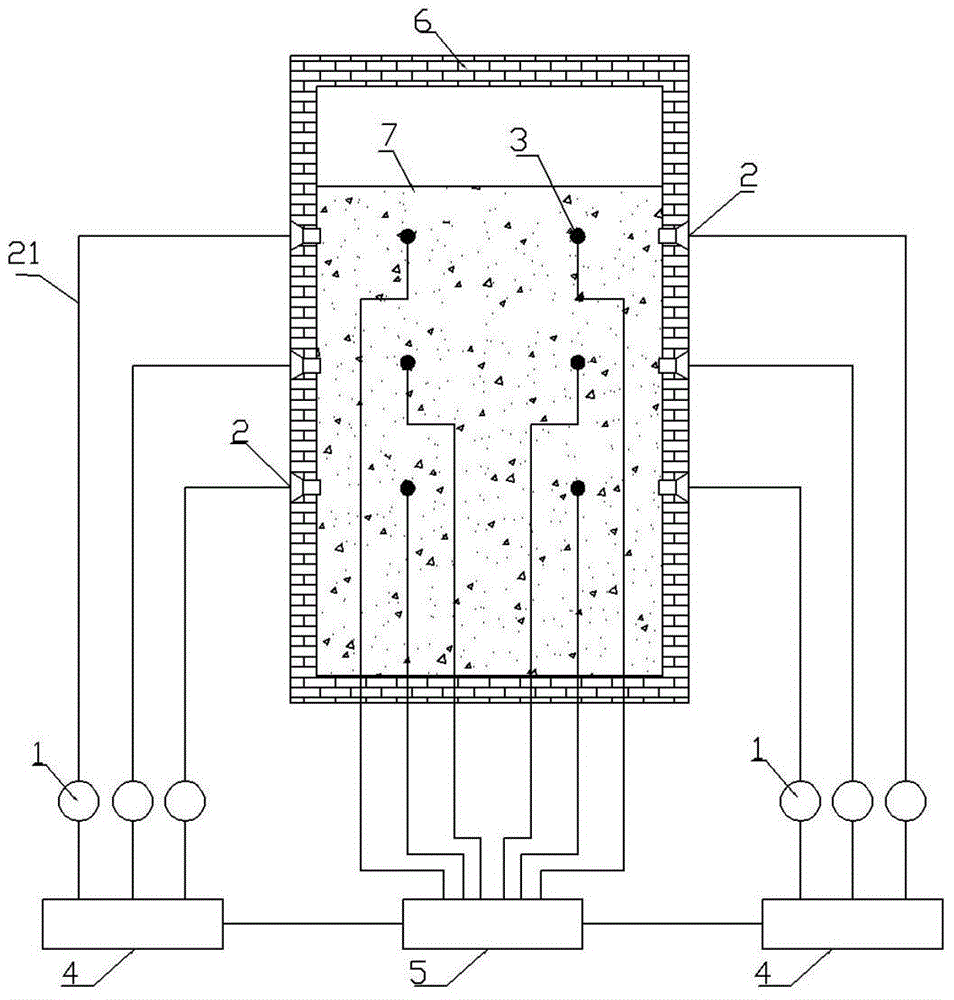

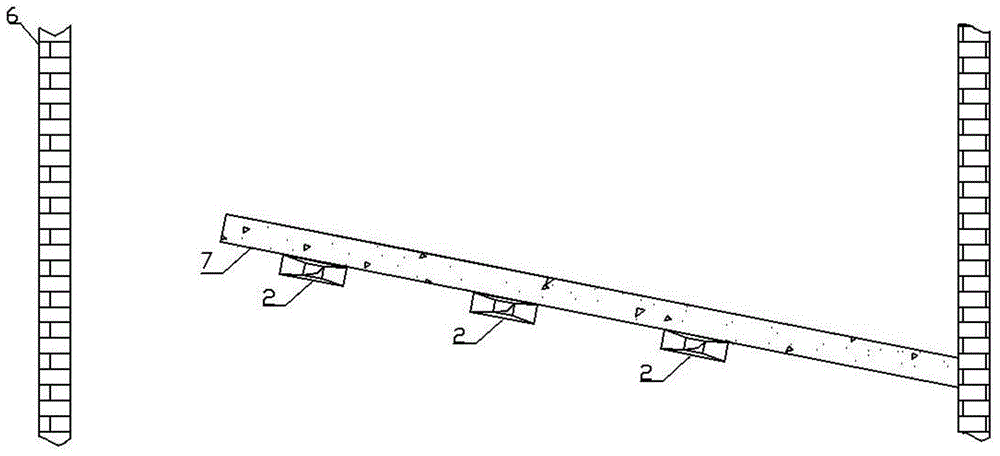

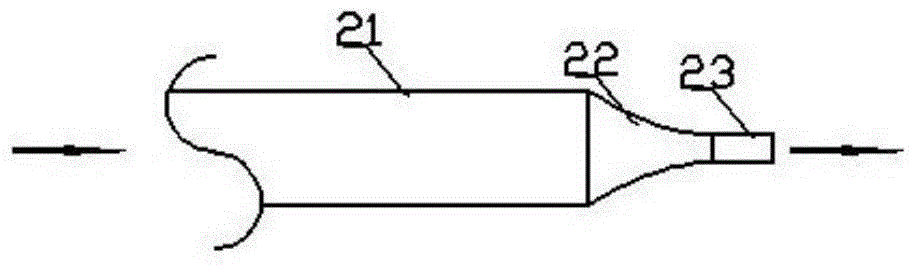

[0017] Such as Figure 1 ~ Figure 3 As shown, a high-temperature incinerator combustion hood 7 air curtain protection system includes a cooling air blower 1 and a cooling air nozzle 2, the cooling air blower 1 is connected to the cooling air nozzle 2 through a cooling air supply pipe 21, and is characterized in that: cooling The air spout 2 is installed on the furnace wall 6 of the incinerator, close to the bottom of the contact part between the combustion cover 7 and the furnace wall 6, the cooling air spout 2 is composed of a necking 22 and a nozzle 23, the nozzle 23 is a flat nozzle 23, the necking 22 is funnel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com