Ultrasonic descaling high-pressure heat exchanger

An ultrasonic and heat exchanger technology is applied in the field of ultrasonic descaling high-pressure heat exchangers, which can solve the problems of high air tightness requirements, difficult shape processing, and labor costs for the aluminum plate-fin heat exchangers. Simple structure, quicker exchange speed, and the effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

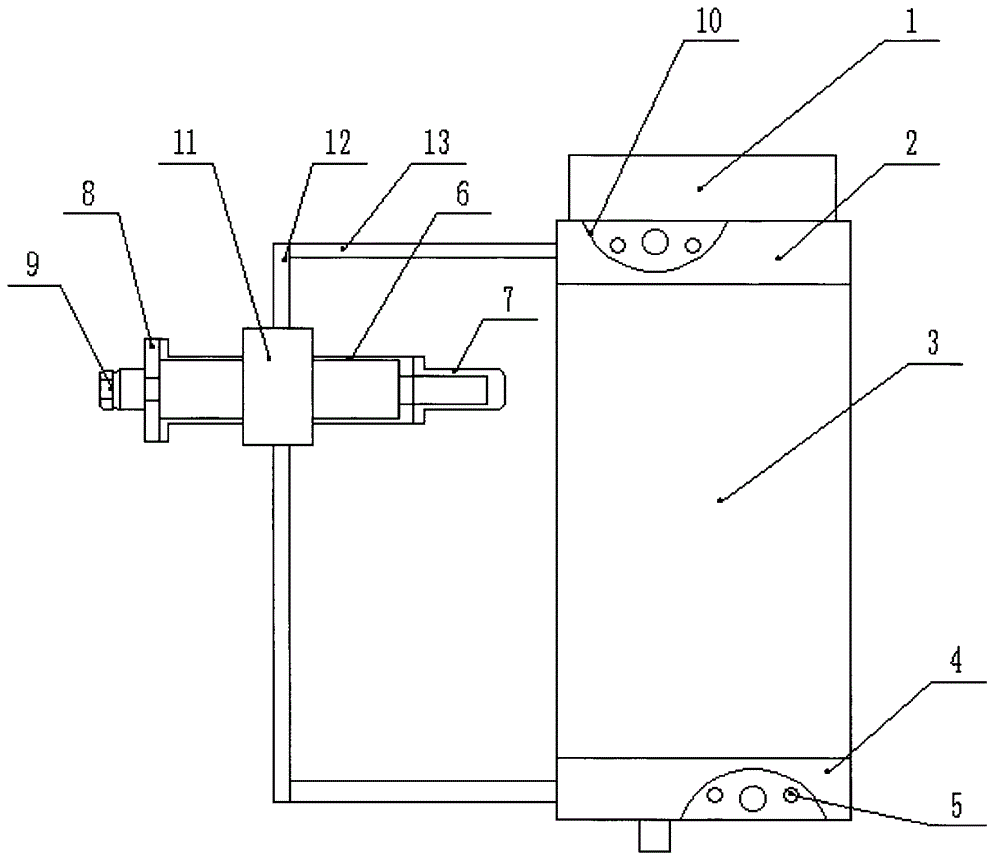

[0011] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0012] see figure 1 , in an embodiment of the present invention, an ultrasonic descaling high-pressure heat exchanger includes a main body 1, a core body 3 located in the middle of the main body 1, and an ultrasonic descaling device; wherein, the upper end of the core body 3 is connected to the first head 2 docking, the lower end of the core body 3 is docked with the second head 4, the side faces of the core body 3 and the first head 2 and the second head 4 are positioned by embedded positioning blocks, and the core body 3 is connected to the first head 4 The head 2 and the second head 4 are docked to form a cuboid, and arc-shaped grooves are arranged on the outside of the sides of the first head 2 and the second head 4, and arc-shaped grooves are embedded in the arc-shaped grooves. Shaped steel sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com