Relay capable of preventing large-current contact separation

A contact separation, electromagnetic relay technology, applied in the direction of electromagnetic relay, relay, electromagnetic relay detailed information, etc., can solve the problems of increasing arc ablation, easy separation of contacts, contact bonding, etc., to solve the problem of contact bounce, Avoid contact bonding and solve the effect of contact separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

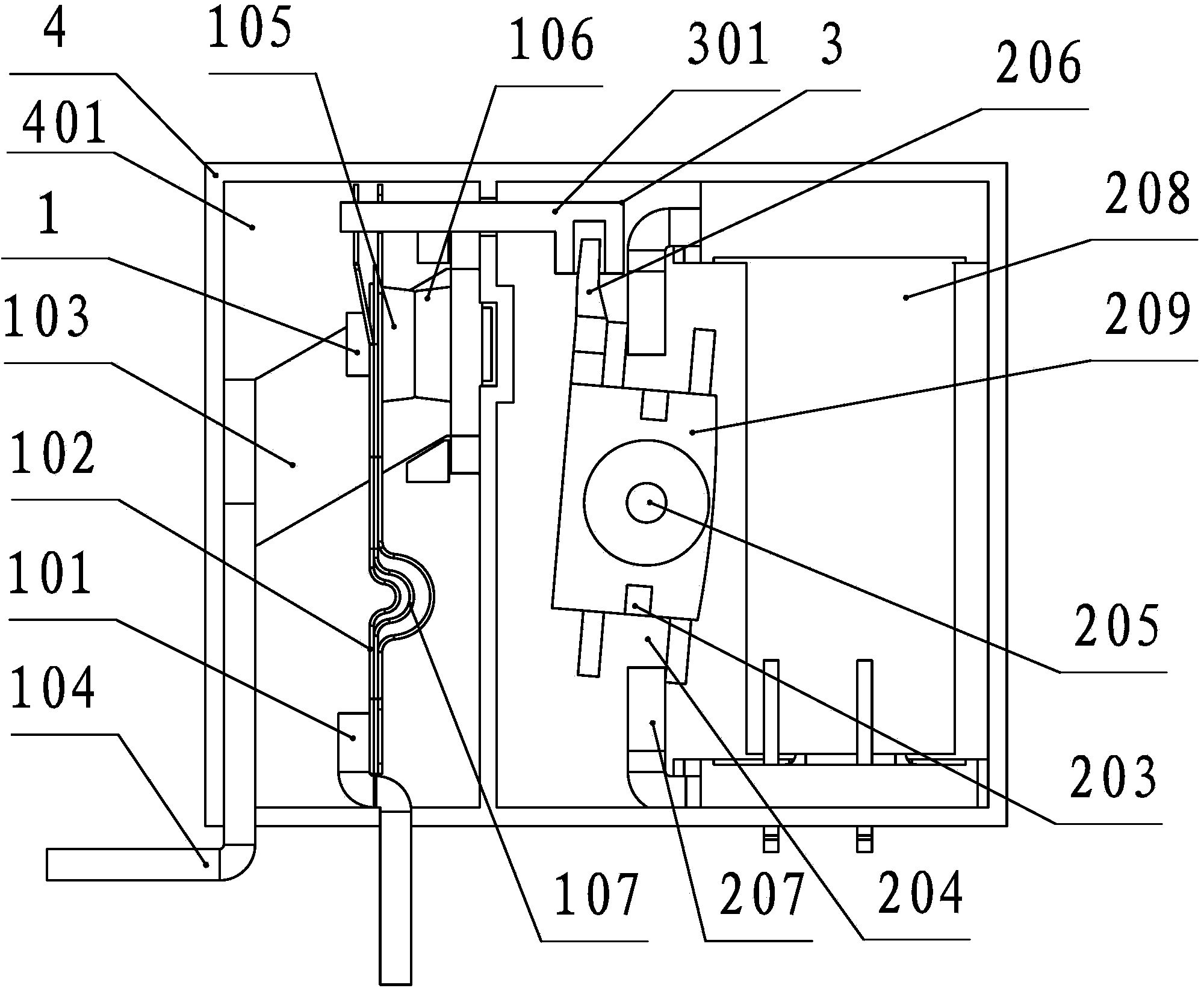

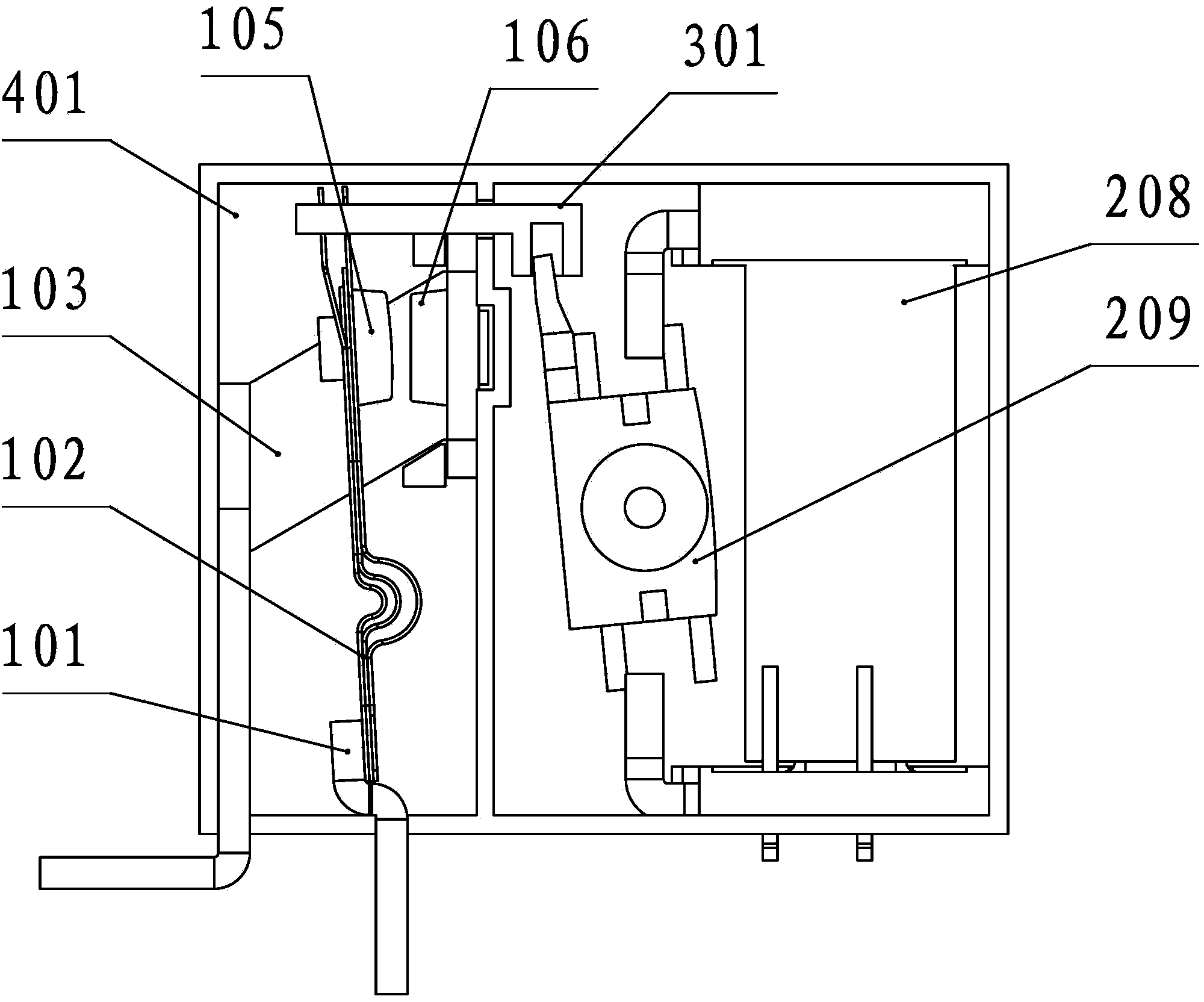

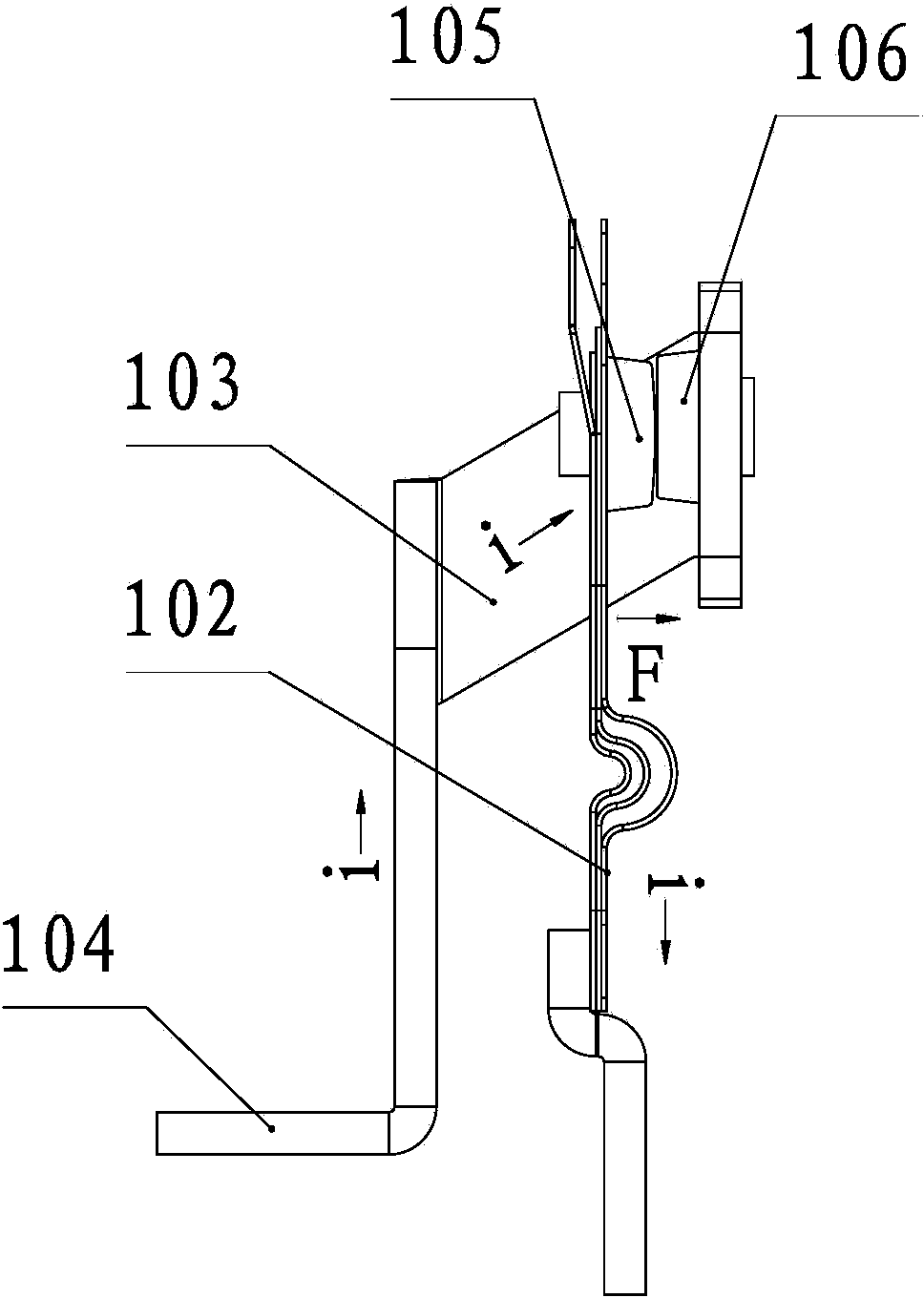

[0026] The following is attached Figures 1 to 10 The given examples further illustrate the specific implementation of the electromagnetic relay for preventing separation of high-current contacts of the present invention. The electromagnetic relay of the present invention is not limited to the description of the following embodiments.

[0027] Such as Figure 1-6 As shown, the electromagnetic relay of the present invention includes a housing 4 and a contact system 1 , an electromagnetic system 2 and a pusher 3 arranged in the housing 4 . The contact system 1 includes a static piece 103 with a static contact 106 and a moving reed 102 with a moving contact 105; the moving reed 102 is connected with the pusher 3, and the pusher 3 is connected with the electromagnetic system 2, and the electromagnetic system 2 The moving reed 102 can be driven to swing by the pusher 3 to realize the opening and closing of the moving contact 105 and the static contact 106, and the connection or d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com