Combined distribution type automatic gas fireproof safe system and application method thereof

A safety system and distribution technology, applied in the field of combined distribution automatic gas fire safety system, can solve problems such as inability to achieve no harm to personnel, gas injury, and difficulty in reaching, and avoid the risk of high-pressure container explosion or poisonous gas injury accident risk, Conducive to moisture-proof and anti-corrosion, easy to popularize and apply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

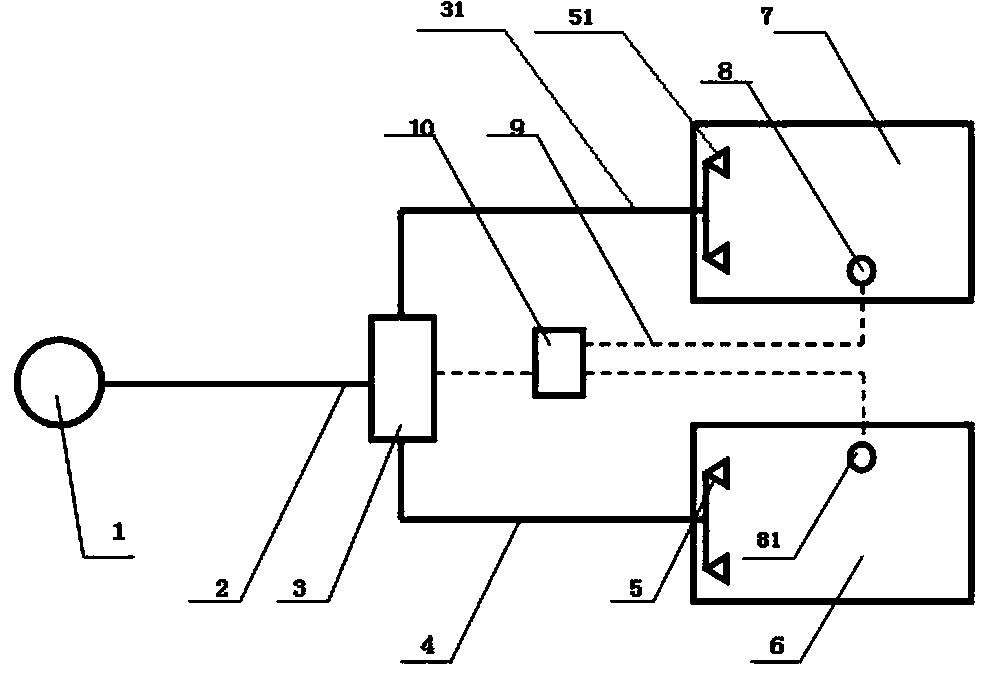

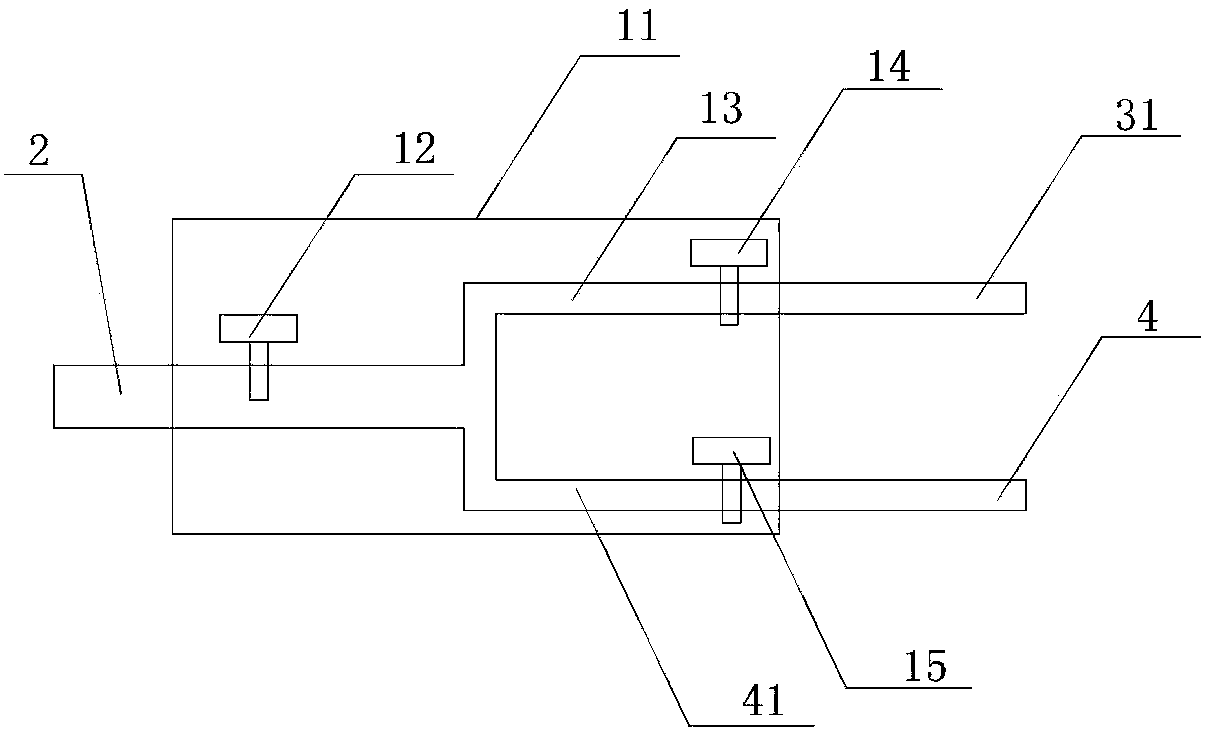

[0039] Such as figure 1 A combined dispensing automatic gas fire safety system is described that includes a nitrogen source 1 capable of providing a high concentration of nitrogen. According to the conditions, the source of nitrogen can be the nitrogen by-product of a factory (such as fertilizer plant or steel plant, etc.), or the nitrogen produced by conventional physical separation technology. Fire protection space A6 and fire protection space B7, main gas supply pipeline 2, combined distribution device 3, nitrogen distribution pipeline A4, nitrogen distribution pipeline B31, nitrogen gas outlet A5, nitrogen gas outlet B51, oxygen concentration detection device A7, oxygen concentration detection Device B71, control line 8 and control device 9.

[0040] The nitrogen source 1 is connected to the on-site combined distribution device 3 through the main gas supply pipeline 2, and then connected to the relatively closed fire protection space A6 and fire protection space B7 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com