Slag crusher

A slag and mechanical treatment technology, applied in the field of slag crushers, can solve the problems of limited production capacity, uncontrolled, uncertain treatment density of slag flow, etc., and achieve the effect of high treatment density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

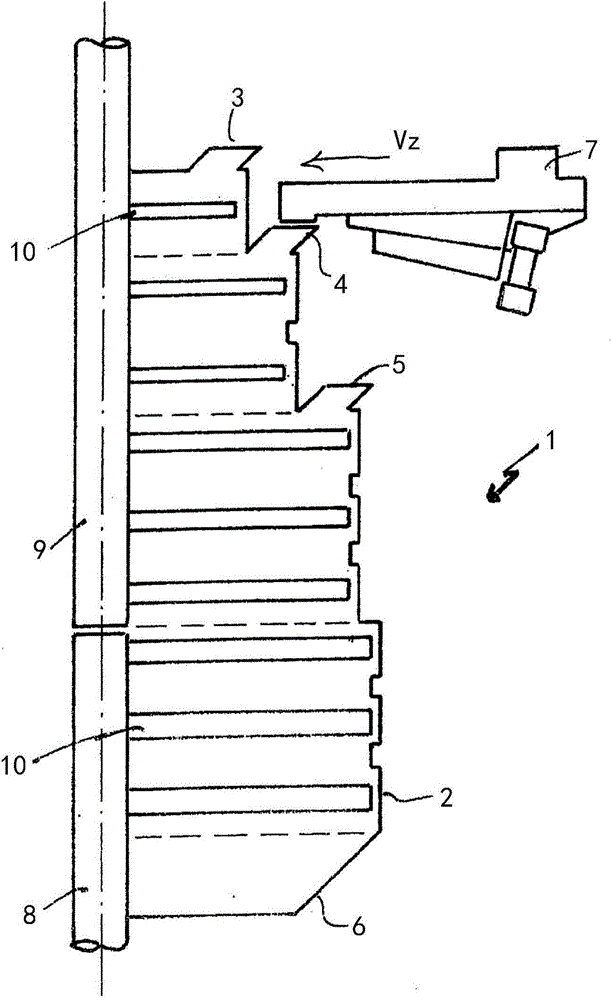

[0049] like figure 1 As shown, the treatment device or crusher 1 has a housing 2 . In the embodiment shown, the housing 2 has filling openings 3 , 4 , 5 . These filling openings can be closed by caps, not shown. An outlet opening 6 is provided in the lower region.

[0050] In the illustrated embodiment, a slag conveying device is shown in the region of the filling opening 4 , with which the slag flow can be dimensioned or controlled.

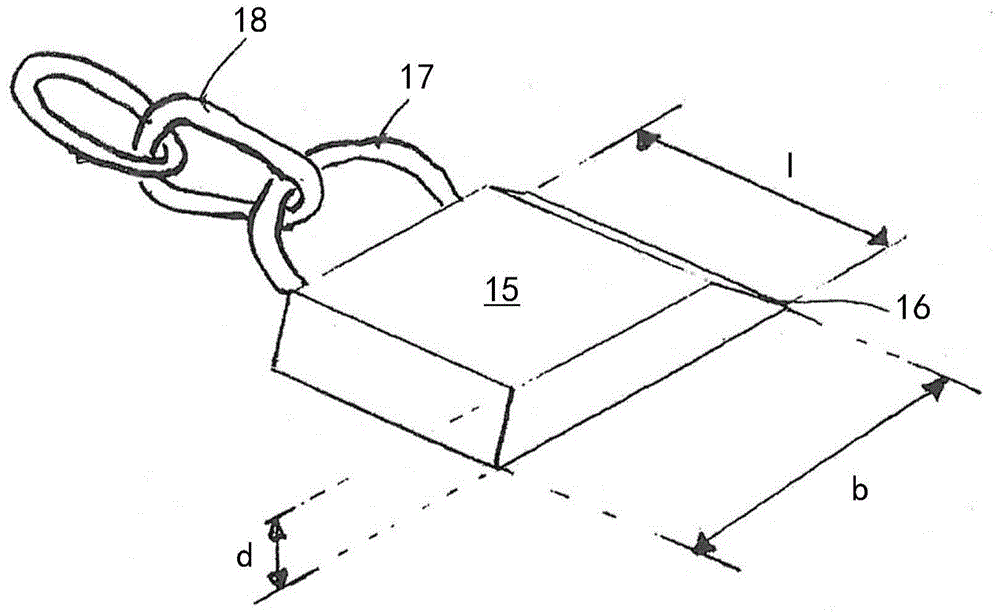

[0051] In the vertical center of the housing 2 are shown drive shafts 8 , 9 on which a plurality of rotor elements 10 are fastened. In this embodiment, these rotor elements are shown as paddles, but could also be impactors fixed to chains or the like.

[0052] The slag crusher 1 works like this: the slag is loaded into one or more filling ports 3, 4, 5, and then these slags pass through different rotor planes and are processed accordingly by the rotor, wherein the slag The components strike the impact element and are thereby split or crushe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com