Multifunctional bidirectional hydraulic bearing puller

A two-way hydraulic and disassembler technology, used in metal processing, metal processing equipment, hand-held tools, etc., can solve problems such as inability to remove bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

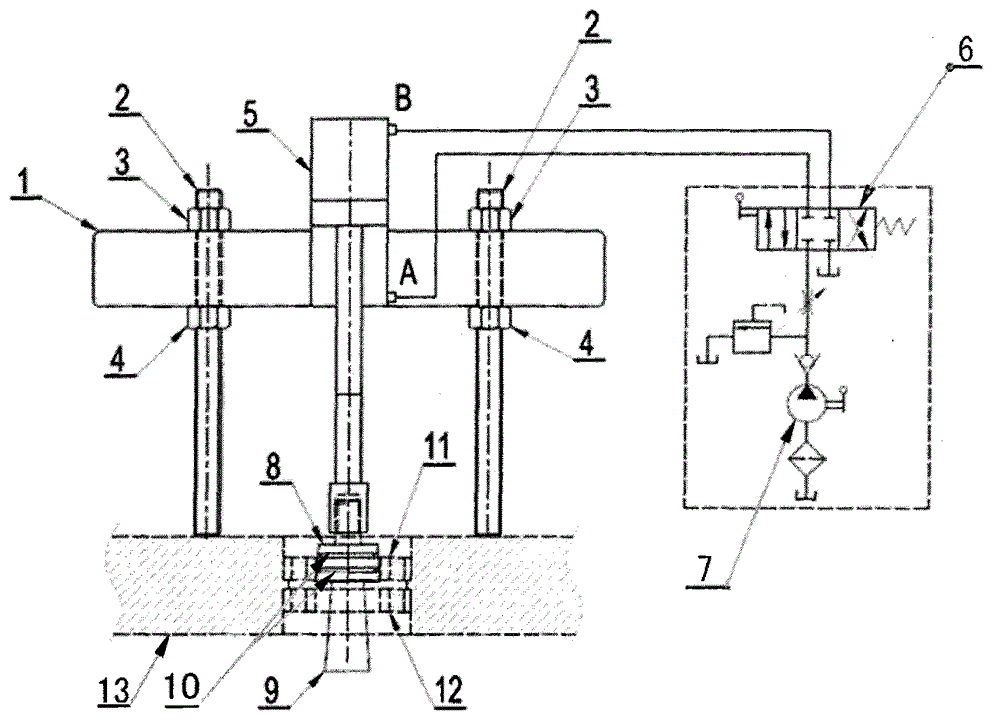

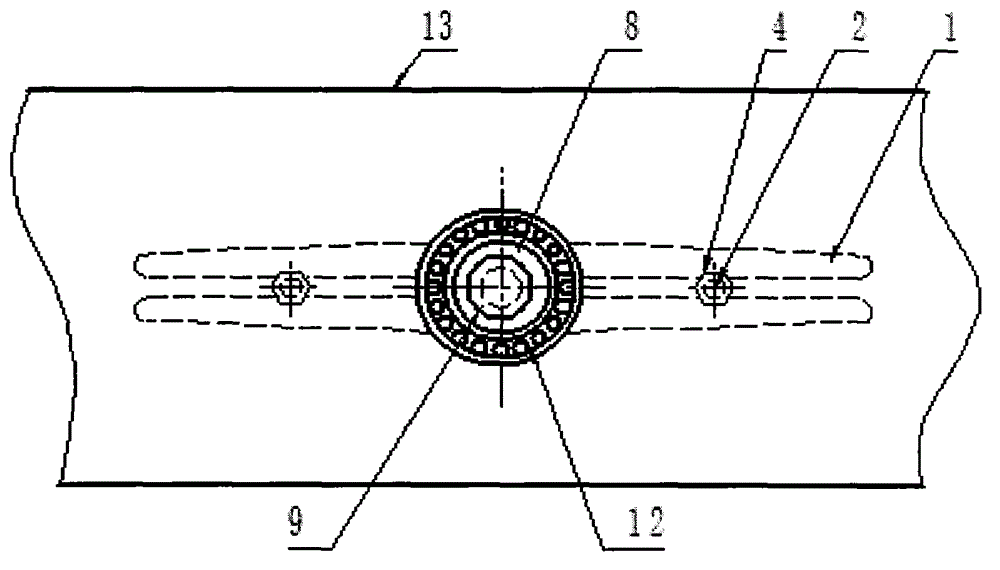

[0013] see Figure 1-2 , a multi-functional two-way hydraulic bearing remover, which includes a bracket 1, two adjustment grooves are respectively opened on the edges of the two sides of the bracket 1, and movable struts 2 are arranged in the adjustment grooves, and each independent movable strut 2. The upper adjustment nut 3 and the lower adjustment nut 4 are fixed on the support 1 by clamping and fitting with the upper adjustment nut 3 and the lower adjustment nut 4. A double-acting hydraulic cylinder 5 is fixed at the center of the middle part of the support 1. The piston rod of the double-acting hydraulic cylinder 5 The end part is connected with the taper pin 9 through threaded coupling. The double-acting hydraulic cylinder 5 is supplied with oil by the hydraulic pump 7, and the direction is changed through the manual reversing valve 6. The outside of the taper pin 9 is provided with The adjusting taper sleeve 8 that fits with it.

[0014] The adjustment taper sleeve 8 i...

Embodiment 2

[0017] 1. Extend the adjusting taper sleeve 8 together with the taper pin 9 into the inner ring of the bearing 11 from the direction where the bearing is to be taken out, and at the same time adjust the relative position between the taper sleeve 8 and the taper pin 9 so that the adjusting taper sleeve 8 expands and the lower end protrudes slightly The inside of the inner ring of the bearing 11 is fully attached to the inner ring of the bearing.

[0018] 2. Adjust the position of the movable support 2 to make it in a suitable position and support height, and then fix and adjust the upper adjustment nut 3 and the lower adjustment nut 4.

[0019] 3. Using the hydraulic pump 7, through the manual reversing valve 6, the hydraulic oil flows in from the A port of the hydraulic cylinder 5 and flows out from the B port, and the plunger moves upward to pull out the bearing.

[0020] The taper sleeve 8 can be replaced and adjusted according to the inner diameters of different bearings to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com