Full-automatic assembly machine for fiber splicing thermal shrinkage protective casings

A technology for protective sleeve and optical fiber fusion, which is applied in the fields of mechanical automation and machinery, and can solve problems such as low production efficiency, difficulty in splicing fiber protection tubes, and reducing mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

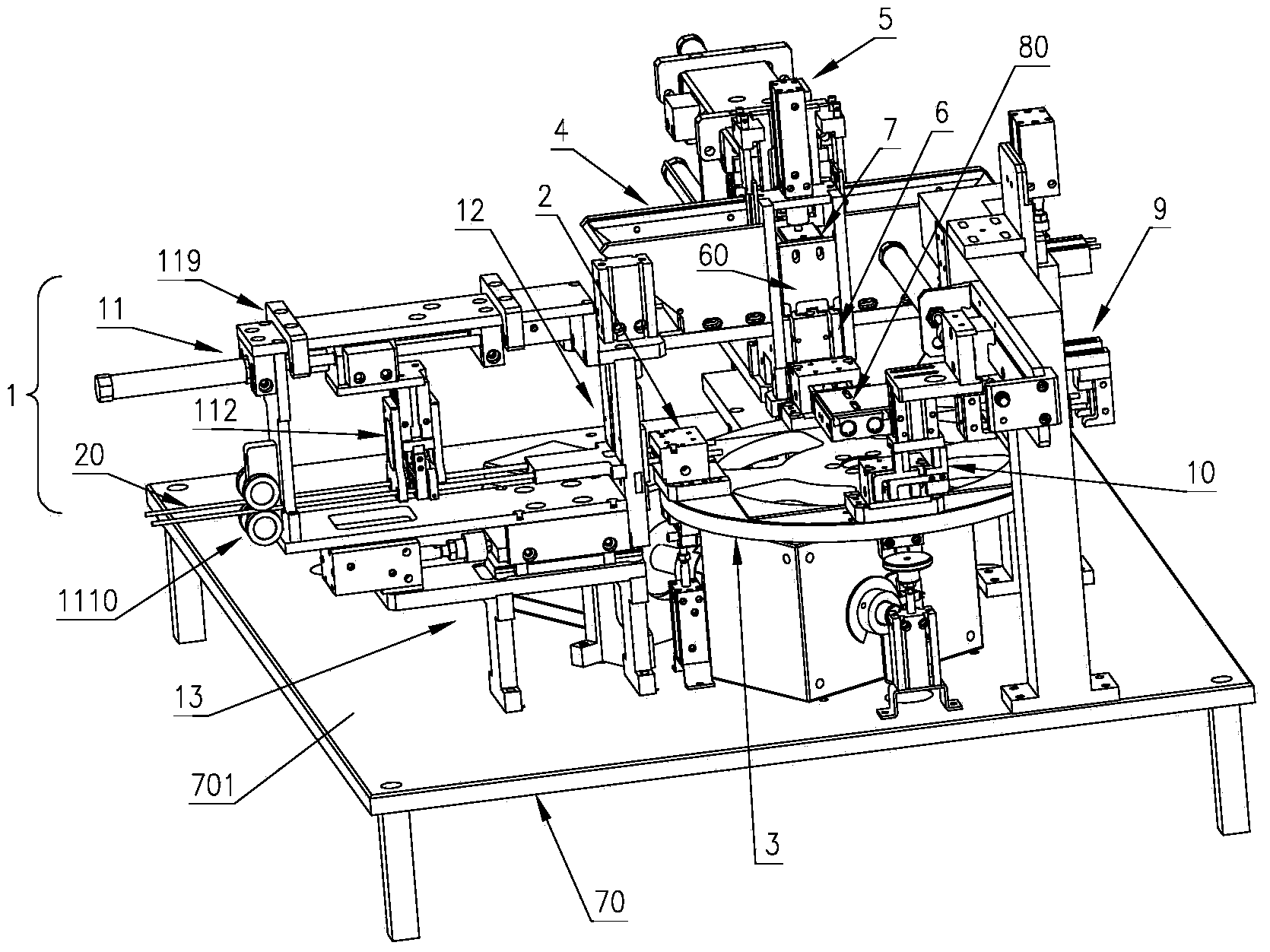

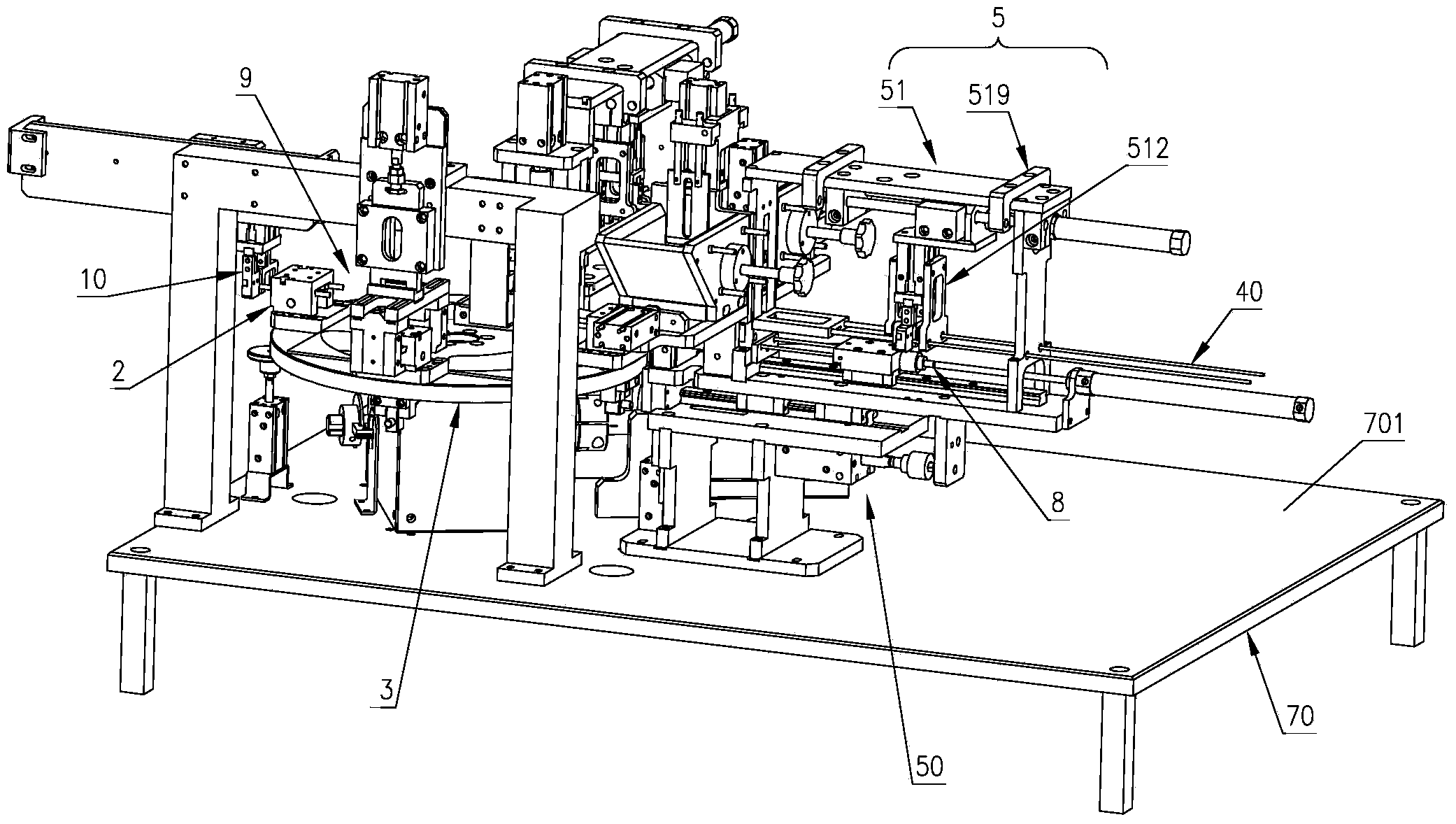

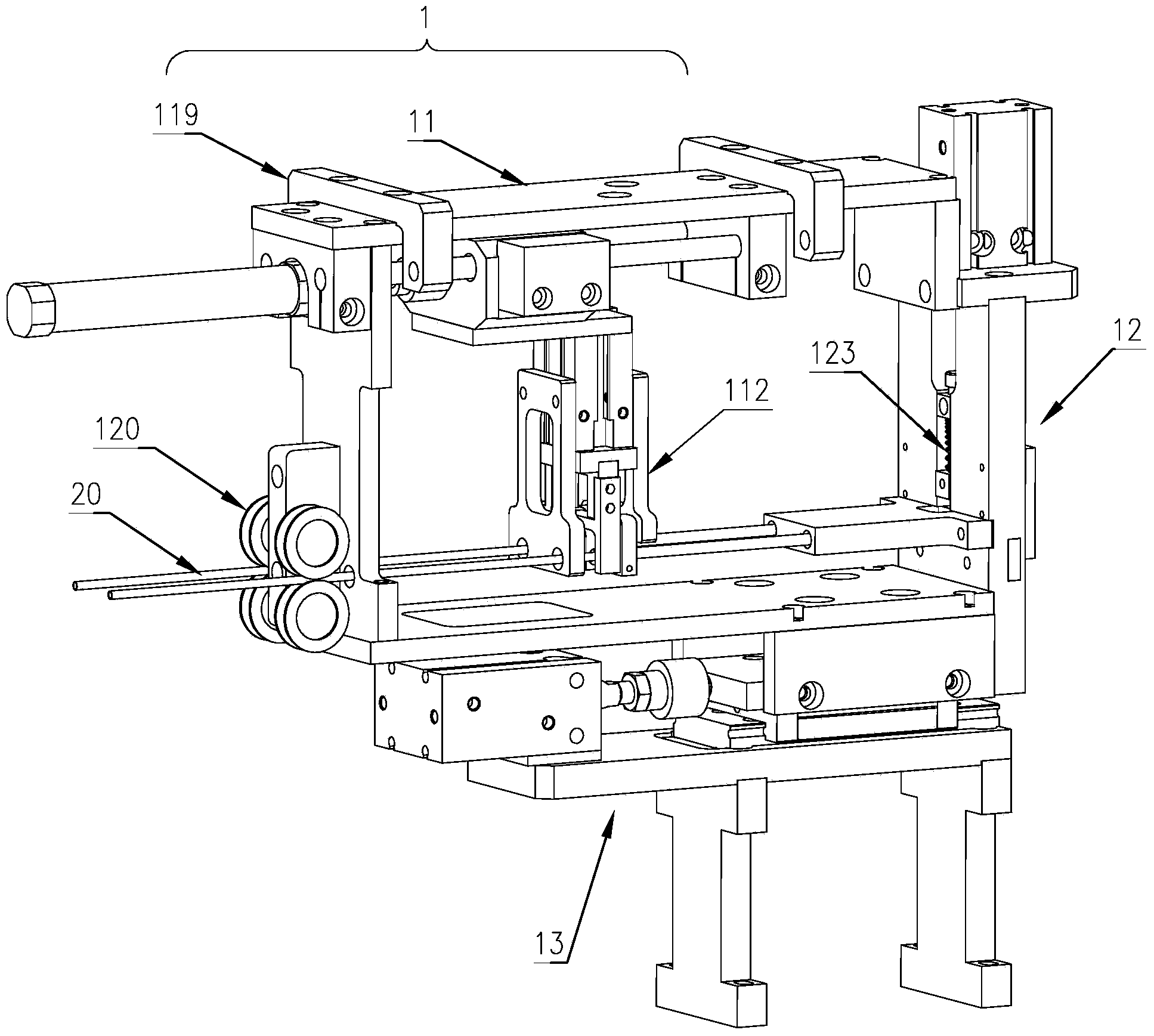

[0033] Such as figure 1 and figure 2 As shown, the fully automatic assembly machine for optical fiber fusion splicing heat-shrinkable protective sleeve of the present invention includes a heat-shrinkable tube automatic conveying and cutting device 1, a heat-shrinkable tube clamping device 2, a turntable assembly 3, a steel needle automatic material-distributing conveying device 4, Hot-melt pipe automatic conveying and cutting device 5 , workpiece carrier 6 , pushing device 7 , assembling device 8 , blanching device 9 , retrieving device 10 and frame 70 .

[0034] Specifically, such as figure 1 , figure 2 and Figure 22 As shown, the rack 70 is provided with a rack deck 701 . The workpiece carrier 6 is a carrier for accommodating the steel needle 30 and the hot-melt tube 40 before assembly. It is provided with two U-shaped grooves 61. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com