Device and method for automatic cleaning of PS and ABS waste and old plastic

A waste plastic, automatic cleaning technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning methods using liquids, etc., can solve the problems of low impurity removal rate, inability to clean waste plastics in batches, etc. The effect of good ROHS test results and shortened process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

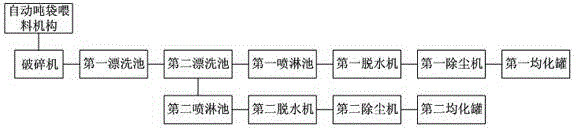

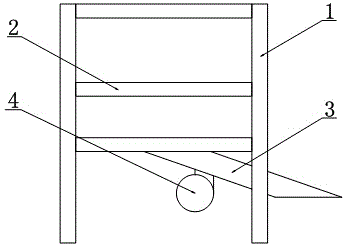

[0038] Such as figure 1 As shown, the present invention is mainly used for crushing and cleaning PS and ABS waste plastics, so as to meet the requirements of the subsequent recycling manufacturing process and realize the recycling of waste plastics. In terms of system structure, the present invention includes an automatic big bag feeding mechanism, a crusher, a first rinsing tank, a second rinsing tank, an environmental protection material processing system and a sinking material processing system. The crusher, the first rinsing tank and the second rinsing tank are connected in sequence. The crusher is used to crush waste plastics, and its feeding port is connected with the automatic ton bag feeding mechanism, and as figure 2 As shown, specifically, the automatic big bag feeding mechanism includes a support frame 1, and the big bag placed in the support frame 1 is placed under the discharge rack 2, and is arranged under the big bag placed under the discharge rack 2 and is con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com