Automatic online mark spraying machine for steel plates

An automatic and labeling technology, applied to typewriters, printing, etc., can solve the problems of harsh environment on the job site, huge labeling equipment, and large floor space, and achieve the effect of small footprint, clear labeling content, and light structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

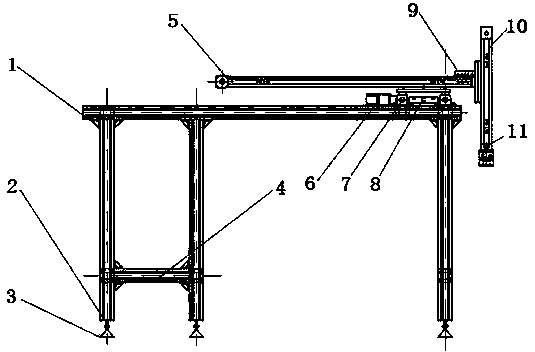

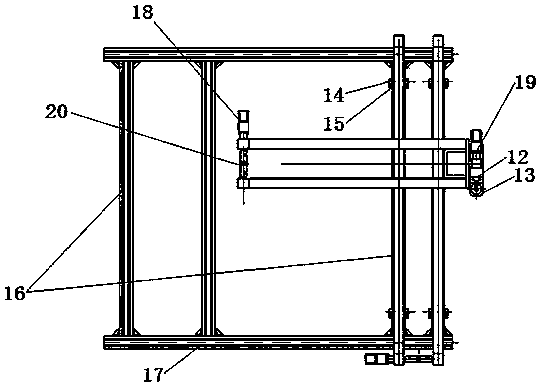

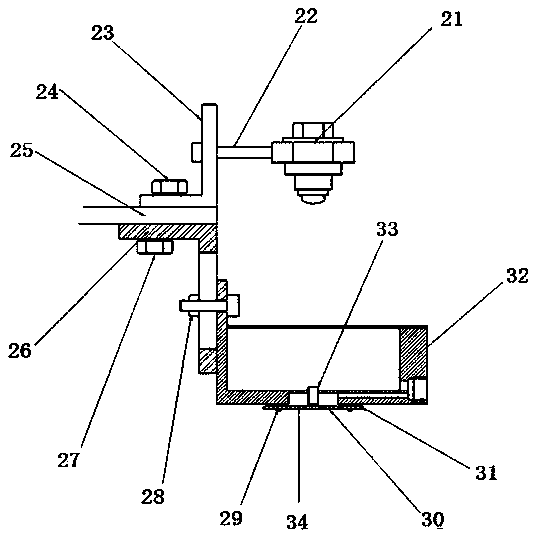

[0038]The drawings of the present invention are as follows: 1-reinforced corner piece; 2-column; 3-supporting foot; 4-connecting column 1; 5-Y axis linear module; 6-X axis servo motor; 7-X axis line Module; 8-X-axis synchronization rod; 9-valve box; 10-Z-axis linear module; 11-nozzle connector; 12-nozzle seat; 13-beam device; 14-installation base plate; 15-fixed block ;16-working beam; 17-beam; 18-Y-axis servo motor; 19-Z-axis servo motor; 20-Y-axis synchronization rod; 21-paint nozzle; 22 nozzle fixing screw; Screw; 25-fixed bottom plate; 26-adjusting plate; 27-fixing screw; 28-fixing bolt, nut; 29-screw; 30-hole plate; 31-sealing gasket; 32-beam plate; -Negative pressure hole; 35-computer; 36-servo control card; 37-terminal board; 38-servo controller; 39-AC servo motor; 40-manual ball valve; 41-air filter; 42-pressure regulating valve; 43 -atomizing gas solenoid valve; 44-cleaning water valve; 45-paint valve; 46-cleaning water valve control solenoid valve; 47-paint valve co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com