Bearing picking and placing device

A pick-and-place device and bearing technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve problems such as easy to rust, affect service life, sweat sticking, etc., achieve high efficiency, not easy to fall off, and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

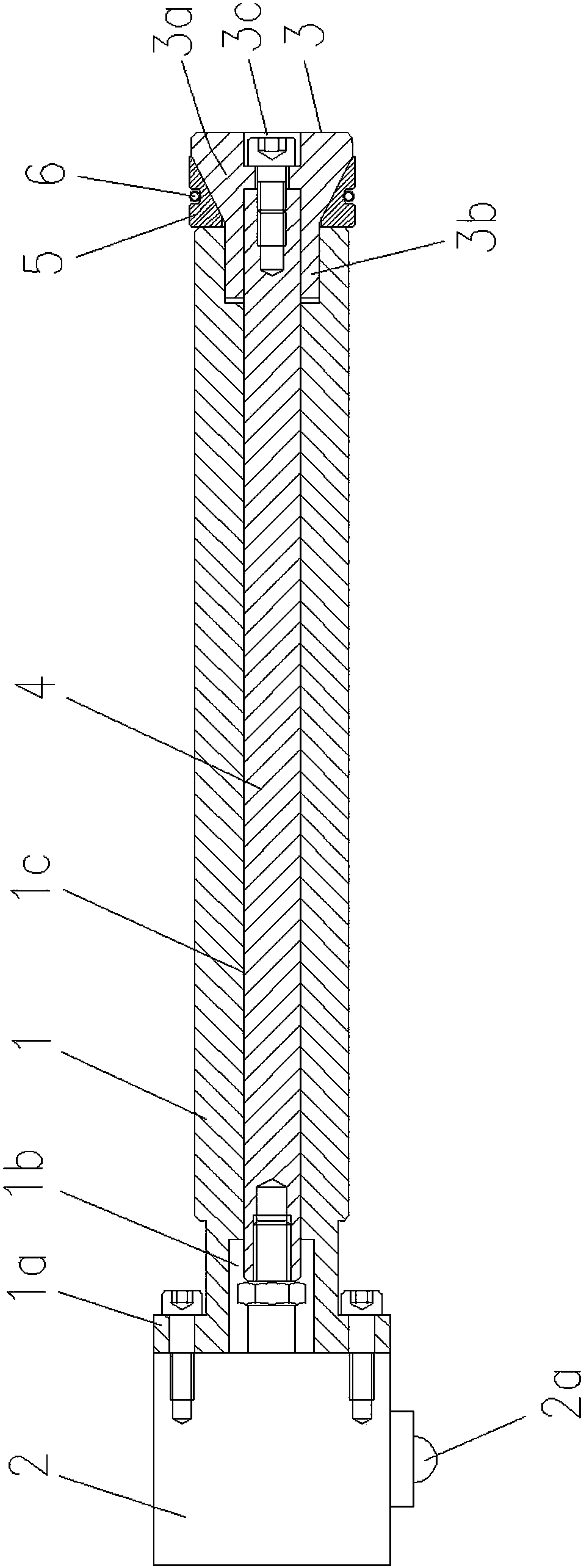

[0015] Such as figure 1 As shown, a bearing pick-and-place device provided by the present invention is characterized in that it includes:

[0016] A sleeve 1, a flange 1a is provided at one end of the sleeve 1, and a counterbore 1b is provided on both sides inside the sleeve 1, and the diameters of the two counterbore 1b are larger than the central hole of the sleeve 1 1c diameter.

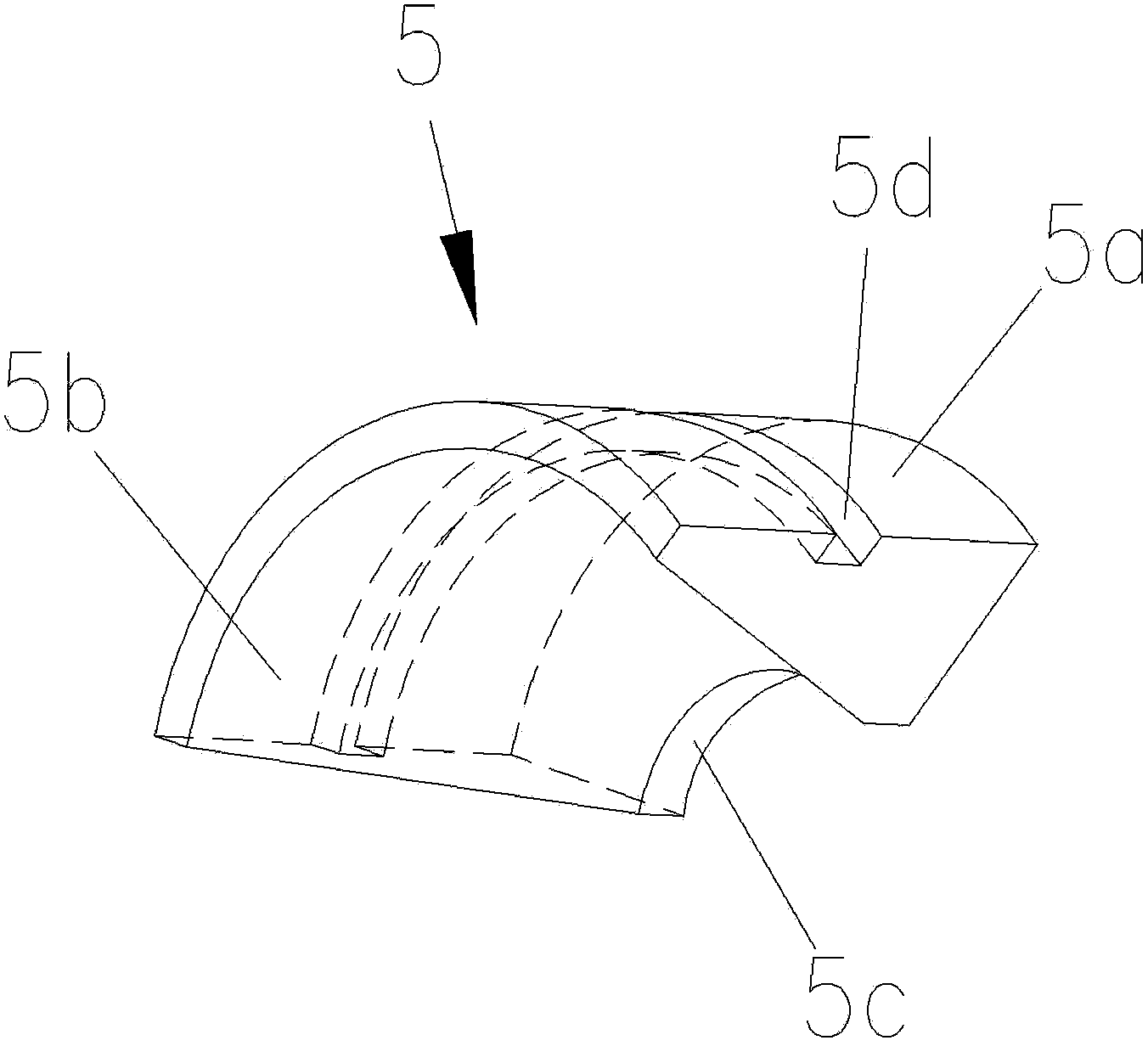

[0017] One end with the flange 1a of the sleeve 1 is fixedly connected with a cylinder 2 by screws, and the other end is slidingly fitted with a moving cone 3, and an operation button 2a is arranged on the cylinder 2, and the cylinder 2 The piston rod is arranged in the corresponding counterbore 1b. A pull rod 4 is slidably connected in the central hole 1c of the sleeve 1 , one end of the pull rod 4 is threadedly connected with the piston rod of the cylinder 2 , and the other end is fixedly connected with the moving cone 3 . Described moving cone 3 is a funnel-shaped structure, and it comprises...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com