Elevator electric control operation rod

An operating rod and electromechanical technology, applied in the field of hoist electric control operating devices, can solve problems such as difficulty in adjusting the center position of the potentiometer, difficulty in controlling the starting speed, and failure to adjust the center position, achieving low power consumption and communication. Rapid breaking and maintenance-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

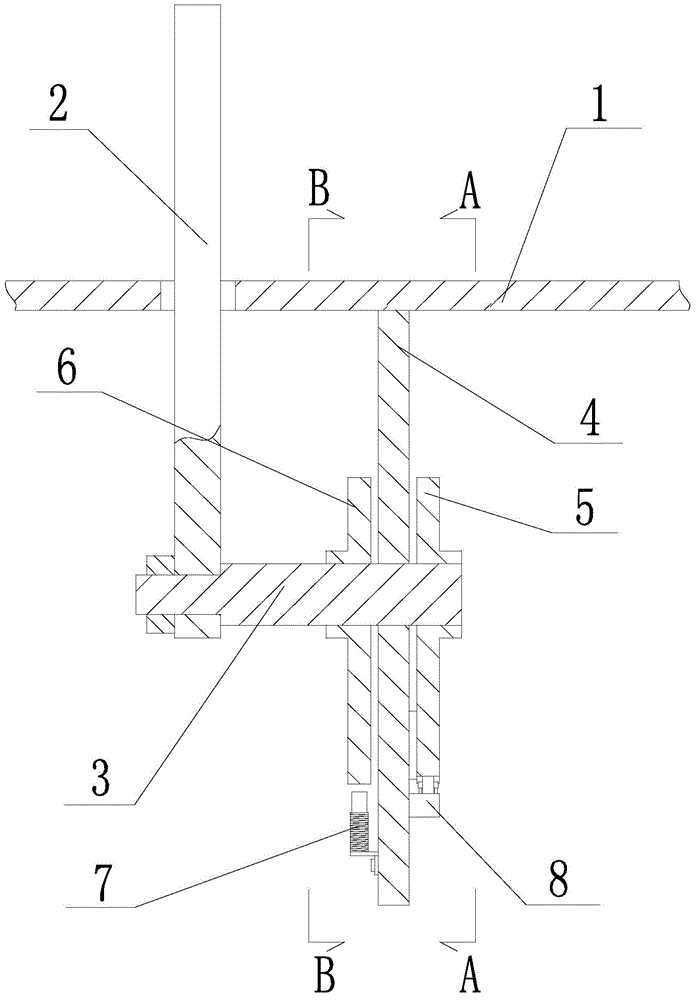

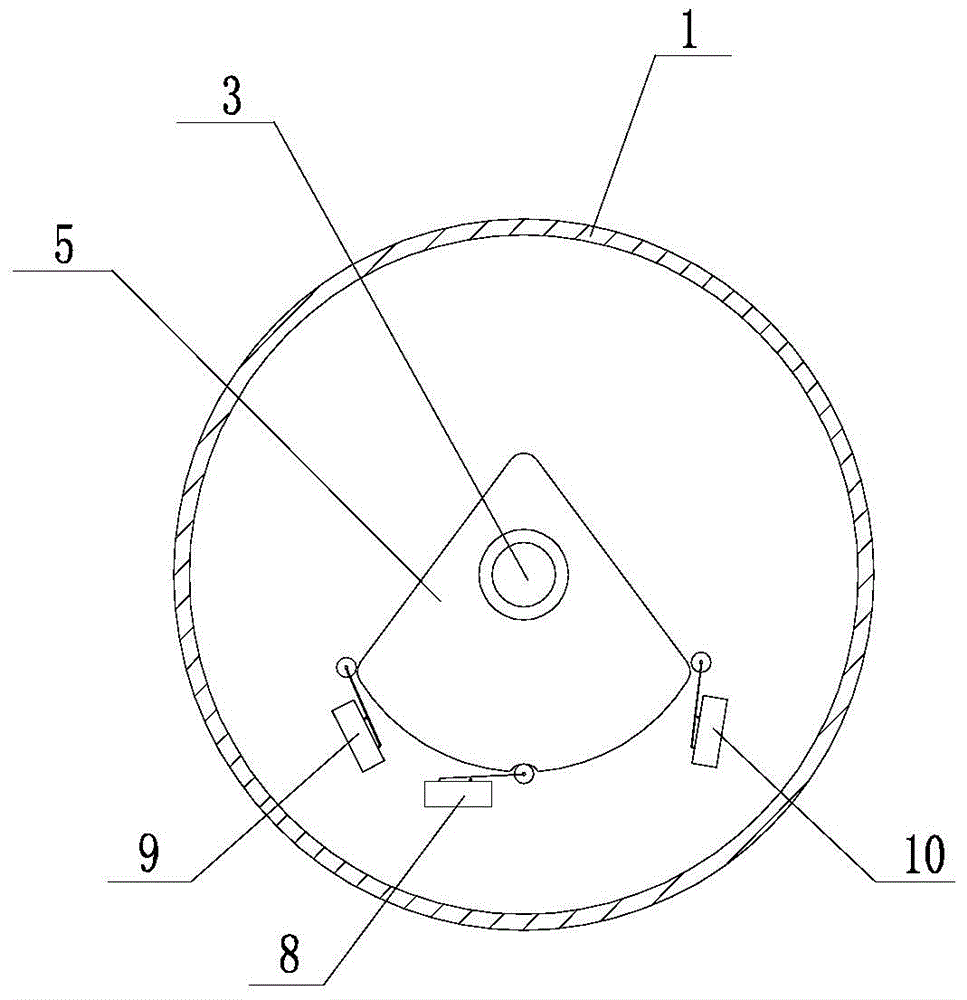

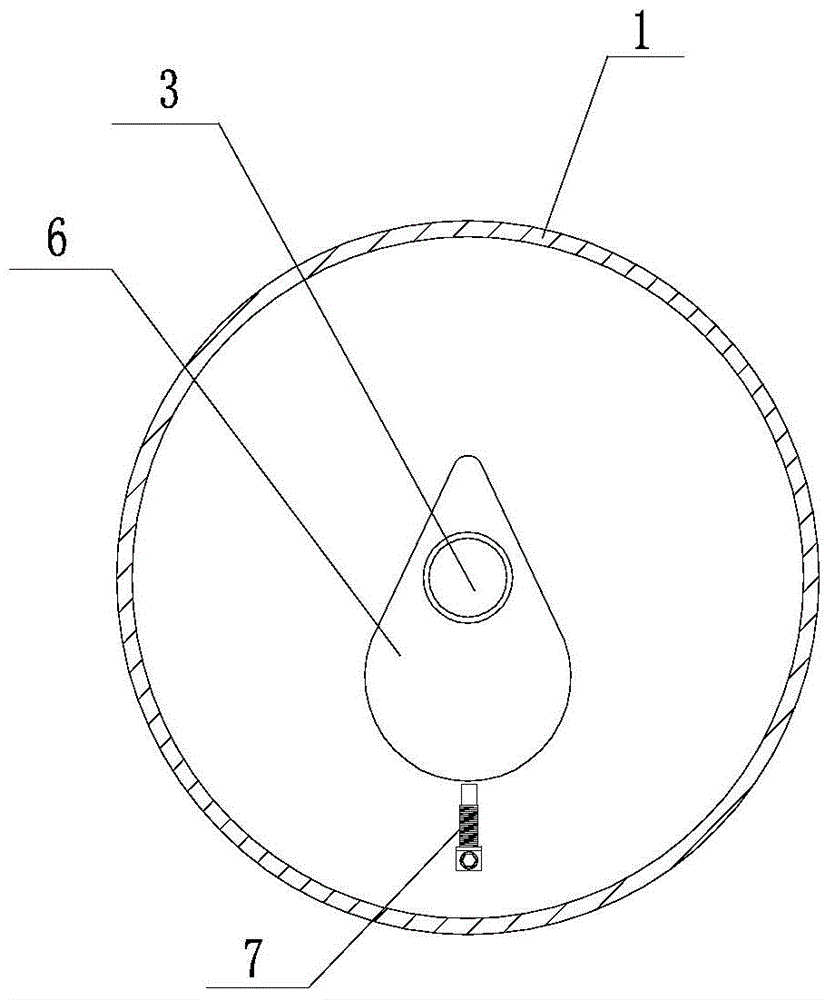

[0016] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 As shown, a hoist electric control operating rod, a bottom plate 4 is installed in the hoist operating table 1, a rotating shaft 3 is installed on the bottom plate 4, an operating rod 2 is installed at one end of the rotating shaft 3, and on both sides of the bottom plate 4 A micro switch cam 5 and a displacement sensor cam 6 are respectively installed on the rotating shaft 3, and a zero position notch 11 is provided on the micro switch cam 5, and a zero position micro switch is respectively installed on one side of the micro switch cam 5 on the bottom plate 4. Move the switch 8, lift the micro switch 9, lower the micro switch 10, the contact of the zero position micro switch 8 is stuck in the zero position notch 11; on the bottom plate 4, the displacement sensor cam 6 side is equipped with a displacement sensor 7 , the displacement sensor 7 is a Hall-type displacemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com