Electroless copper plating solution

A technology of electroless copper plating and plating solution, applied in liquid chemical plating, metal material coating process, coating, etc., can solve problems such as reducing the plating deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3 and comparative example 1-6

[0031]Add the compounds listed in Table 1 to the base bath below to make the test baths. Next, various resin substrates were plated with the above-mentioned test baths, and the obtained test pieces were evaluated. The results are shown in Table 2.

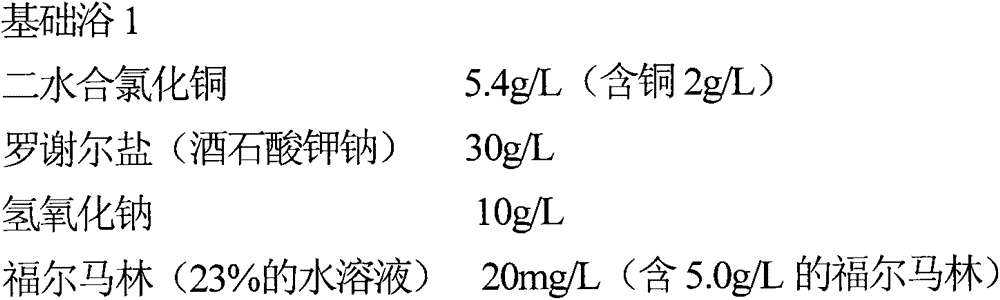

[0032]

Embodiment 4

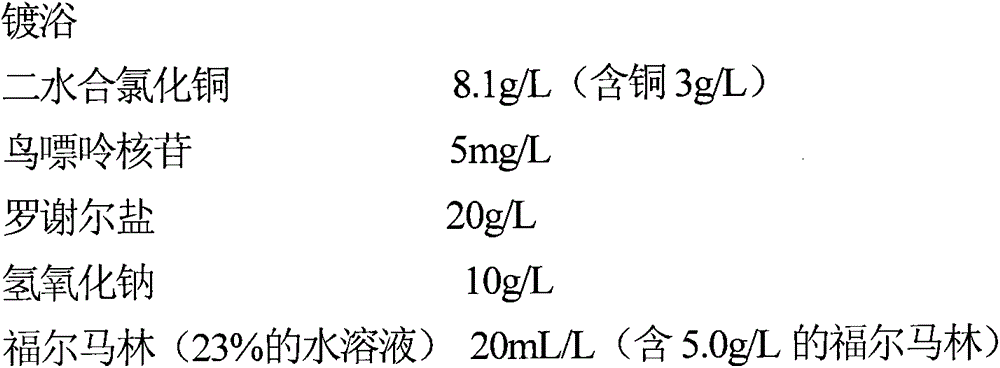

[0034] Except using the below-mentioned plating bath, the same procedure as in Example 1 was carried out, and the obtained test pieces were evaluated, and the results are shown in Table 2.

[0035]

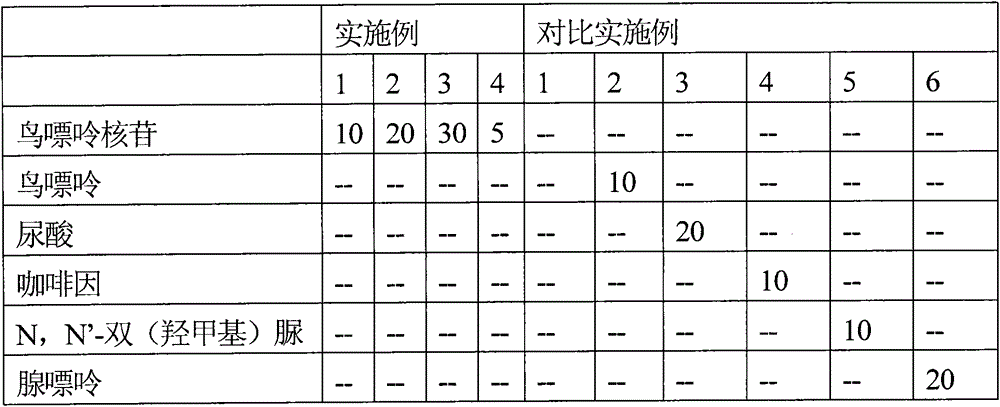

[0036] Table 1

[0037] Table 1. Amount of each compound added (unit: mg / L)

[0038]

[0039] Table 2

[0040] Table 2. Evaluation results

[0041]

[0042] * Plating without deposition

[0043] overall evaluation

[0044] table 3

[0045] overall evaluation

peel stress

Exterior color

A

high

pretty dark 注1)

[0046] B

high

black

C

Low

shallow 注2)

D

Can't detect

Copper powder chemical precipitation

[0047] Note 1) Quite black means good appearance

[0048] Note 2) Indicates that it has the same brightness as the slot not added

[0049] Resin substrate

[0050] Substrate 1: epoxy resin, surface roughness (Ra) 220-260nm

[0051] Substrate 2: epoxy resin, surface r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com