Escape rope and preparation method thereof

An escape rope and rope skin technology, which is applied in the field of escape rope and its preparation, can solve the problems such as the inability to meet the performance requirements of the escape rope, and achieve the effects of compact structure, low ductility and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of this escape rope is realized through the following steps:

[0023] (1) Select raw materials: select high-strength polyester fiber filaments with a specification of 1000D;

[0024] (2) Initial twist: 3 high-strength polyester fiber filaments are combined into one strand, with a twist of 120-160 twists / m; 10 high-strength polyester fiber filaments with a specification of 1000D are combined into one strand, with a twist of 80-120 twist / m;

[0025] (3), re-twisting: take three strands of high-strength polyester fiber strands after primary twisting for re-twisting, and the twist is 50-70 twists / m;

[0026] (4) Pre-weaving: 3 high-strength polyester fiber strands twisted by the twisting machine are pre-woven on the automatic pre-looming machine into bobbins that meet the spindle size of the high-speed weaving machine for weaving;

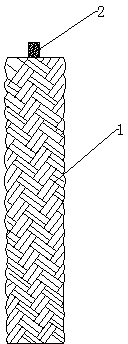

[0027] (5) Rope: The aggregate of 10 high-strength polyester fiber three-strand twisted yarns is the rope core 2, and ...

Embodiment 1

[0029] (1) Select raw materials: select high-strength polyester fiber filaments with a specification of 1000D;

[0030] (2) Initial twist: use 3 high-strength polyester fiber filaments combined into one strand, with a twist of 120 twists / m; 10 high-strength polyester fiber filaments with a specification of 1000D combined into one strand, with a twist of 80 twists / m;

[0031] (3), re-twisting: take three strands of high-strength polyester fiber strands after initial twisting for re-twisting, and the twist is 50 twists / m;

[0032] (4) Pre-weaving: 3 high-strength polyester fiber strands twisted by the twisting machine are pre-woven on the automatic pre-looming machine into bobbins that meet the spindle size of the high-speed weaving machine for weaving;

[0033] (5) Rope: The aggregate of 10 high-strength polyester fiber three-strand twisted yarns is the rope core 2, which is braided according to the S-twist direction of 12 high-strength polyester fiber strands and the Z-twist d...

Embodiment 2

[0035] (1) Select raw materials: select high-strength polyester fiber filaments with a specification of 1000D;

[0036] (2) Initial twist: use 3 high-strength polyester fiber filaments combined into one strand, with a twist of 160 twists / m; 10 high-strength polyester fiber filaments with specifications of 1000D combined into one strand, with a twist of 120 twists / m;

[0037] (3), retwisting: take three strands of high-strength polyester fiber strands after initial twisting for retwisting, and the twist is 70 twists / m;

[0038] (4) Pre-weaving: 3 high-strength polyester fiber strands twisted by the twisting machine are pre-woven on the automatic pre-looming machine into bobbins that meet the spindle size of the high-speed weaving machine for weaving;

[0039] (5) Rope: The aggregate of 10 high-strength polyester fiber three-strand twisted yarns is the rope core 2, which is braided according to the S-twist direction of 24 high-strength polyester fiber strands and the Z-twist dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com