Three-dimensional automatic knitting machine

A knitting machine and automatic technology, applied in the directions of knitted fabrics, textiles and papermaking, can solve the problems of structural integrity damage, difficult realization and low production efficiency of prefabricated parts, and achieve the effect of suitable promotion and use, remarkable effect and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

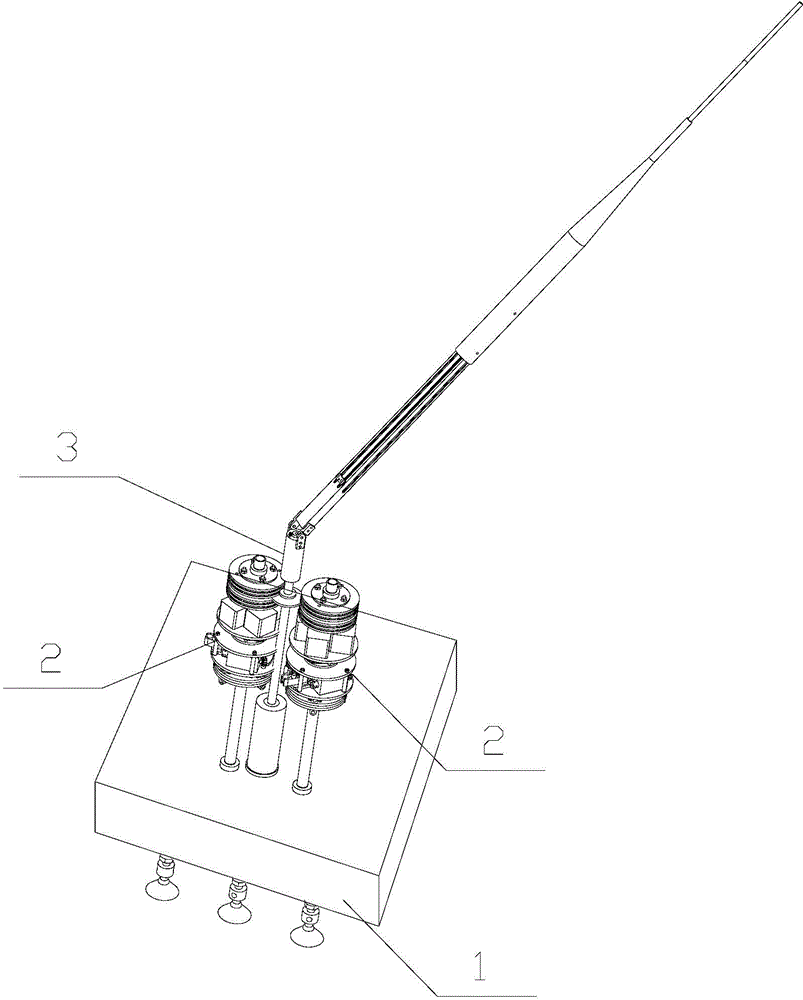

[0050] like figure 1 As shown, in the present embodiment, a kind of three-dimensional automatic knitting machine is characterized in that: comprise by a plurality of knitters 3 that are used to pass the single yarn on the corresponding spool to the knitting surface; Machine base 1; a knitting machine chassis consisting of a plurality of knitting stations 2 installed on the knitting machine base 1; The yarns move to weave into a three-dimensional braid.

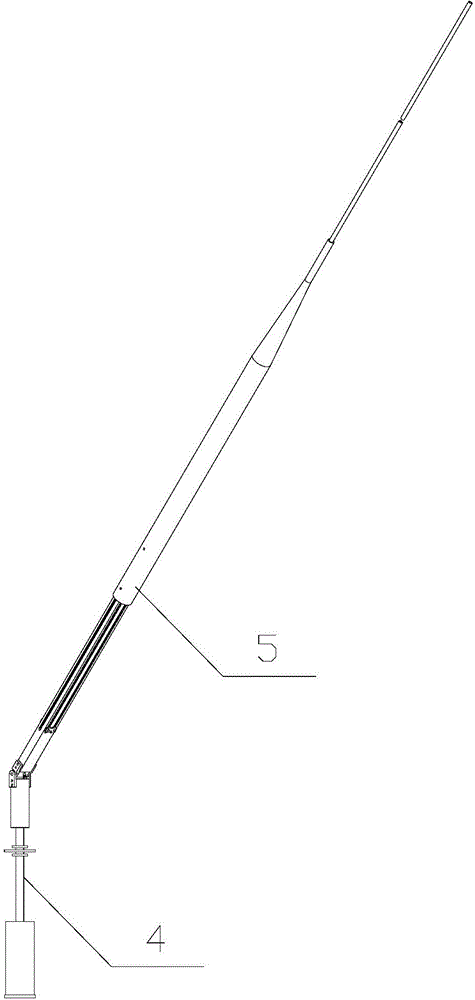

[0051] like figure 2 As shown, in this embodiment, the knitter 3 includes, the knitting section 5 that transmits the yarn from the chassis of the knitting machine to the knitting surface, the support section 4 that fixes the horizontal position of the knitting station, and provides yarn for the knitting machine 3 supply line segment. When performing three-dimensional weaving, the yarns set in the supply segments of each knitter 3 pass through the supporting segment 4 and the knitting segment 5 to the weaving surface in tur...

Embodiment 2

[0055] like figure 2 As shown, in this embodiment, the knitter 3 includes, the knitting section 5 that transmits the yarn from the chassis of the knitting machine to the knitting surface, the support section 4 that fixes the horizontal position of the knitting station, and the knitting section that provides the yarn for the knitting machine. for line segments.

[0056] like Figure 4 As shown, in this embodiment, the thread supply section includes a bobbin box 47, a bobbin 46 arranged in the bobbin box 47, and a wide range tension control system for controlling the tension of the yarn.

[0057] like Figure 4 As shown, in this embodiment, the support section 4 includes a wire tube 44 connected to the bobbin box 47, the wire tube 44 is provided with a support piece 43 for fixing the braider 3, and the wire tube 44 is connected to the bobbin The connecting end of the box 47 is provided with a crimping wheel 45 . The wire tube 44 is arranged as a straight tube inside for the...

Embodiment 3

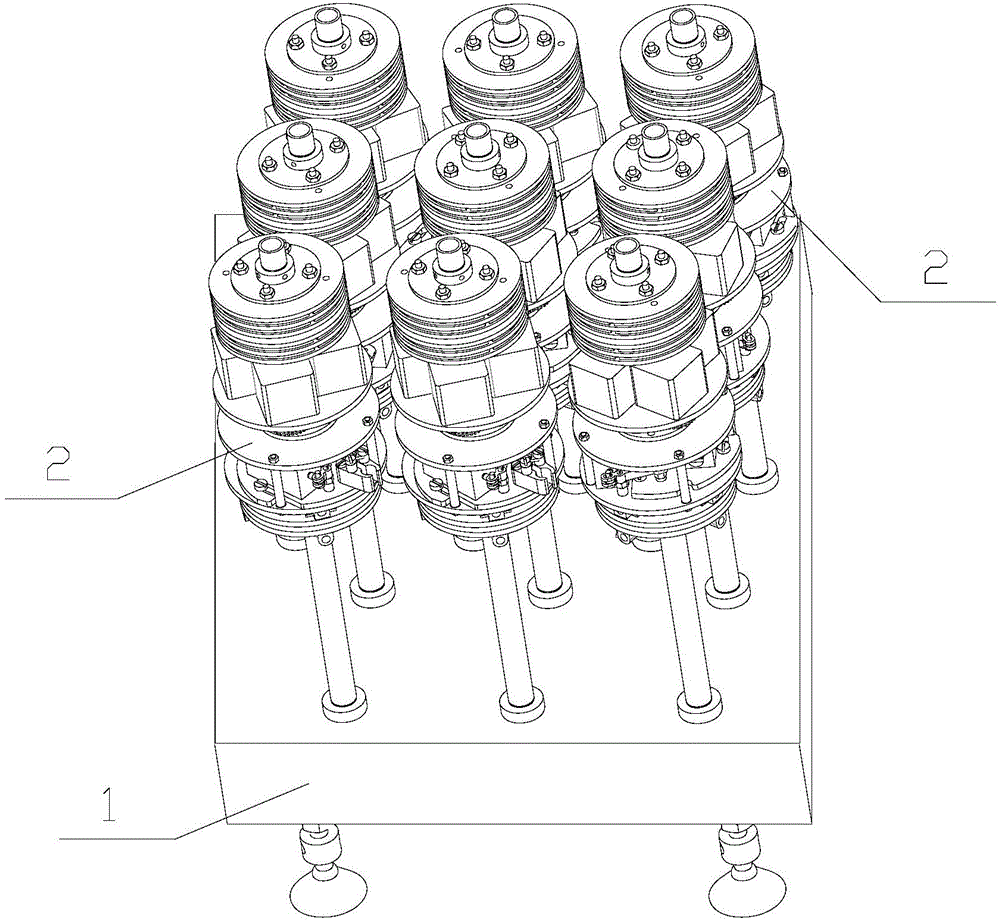

[0062] like image 3 As shown, in the present embodiment, the braiding station 2 is divided into a support layer 23 for fixing the position of the braider 3 and a support layer 23 for making the braider 3 produce a braider 3 from top to bottom with the support tube 21 arranged on the braider base 1 as a pillar. Drive layer 22 for horizontal displacement.

[0063] like Image 6 As shown, in this embodiment, each braiding station 2 is provided with four bobbin sockets 25 shared with adjacent braiding stations 2 , which can fix the braider bobbin 44 at an angle of 90 degrees to each other. The knitting machine 3 can be controllably positioned relative to the knitting station 2 by moving the wire tube 44 between the different wire tube holders 25 .

[0064] like Image 6 As shown, in this embodiment, the support layer 23 is composed of an upper support plate and a lower support plate formed of discs arranged in parallel around the axis of the support tube 21, and a line that ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com