Hanging device for cantilever casting hanging basket

A hanging device and cantilever technology, applied in construction, erection/assembly of bridges, bridges, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the specific implementation of the accompanying drawings.

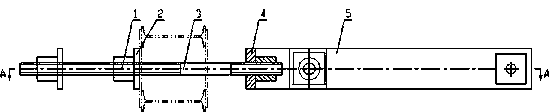

[0023] See attached figure 1 , The hanging device is mainly composed of a nut 1, a spherical washer 2, a double-ended screw rod 3, a conversion coupling 4, a steel plate strap 5, a pin shaft 6, a nut 7, and a nut 8.

[0024] The hanging device is mainly hung on the front beam of the hanging basket and the poured bridge surface. The hanging plate of the hanging device is connected with the bottom mold platform, formwork and sliding beam of the hanging basket, and is an important force-bearing member for intermediate force transmission. It is the connecting member between the hanging basket and the formwork. In addition to being subjected to the hanging tension, there is a certain bending moment during the moving of the basket.

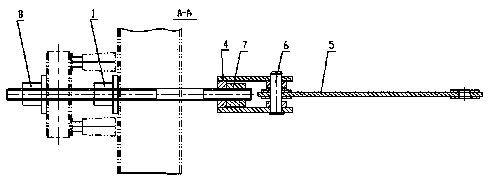

[0025] See attached figure 2 , the key to the hanging device is the application of the conversion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com