Preparation method of tungsten tailing-based geopolymer

A technology for tungsten tailings and geopolymers, applied in cement production and other directions, can solve problems such as accumulation pollution, and achieve the effect of solving accumulation pollution, solving complex operation and excellent compressive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

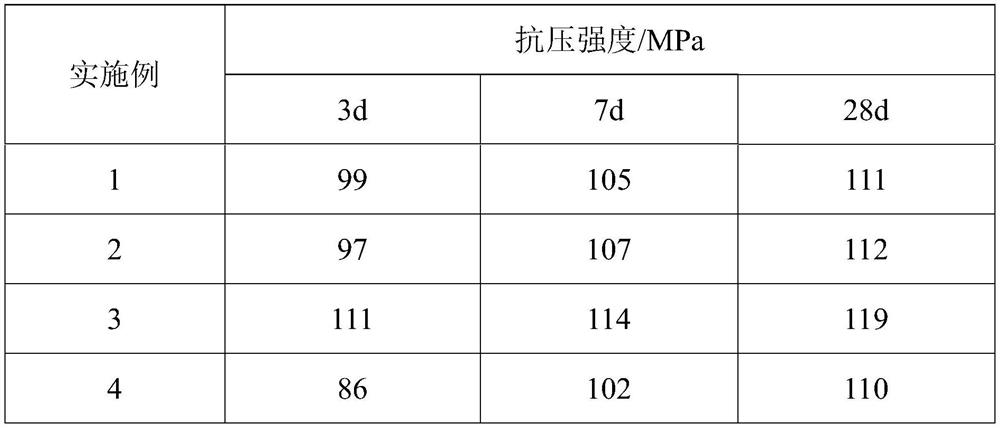

Examples

Embodiment 1

[0027] A preparation method of tungsten tailings base polymer:

[0028] (1) Combine tungsten tailings, fly ash and Na 2 CO 3 Grind separately and pass through a 100-mesh sieve to obtain a powder with a particle size below 100 mesh. Take 100 grams of tungsten tailings powder and 40 grams of Na 2 CO 3 The powder is mixed evenly, 100 grams of fly ash powder and 40 grams of Na 2 CO 3 The powder is mixed evenly; then the tungsten tailings powder and Na 2 CO 3 The powder mixture was calcined at 800 °C for 1 h, and the fly ash powder and Na 2 CO 3 The powder mixture was calcined at 900°C for 1 hour and set aside;

[0029] (2) Put the two calcined products obtained in step (1) into a ball mill and grind them finely, pass through a 100-mesh sieve to obtain a powder with a particle size below 100 mesh, and then mix them uniformly to form a geopolymer precursor;

[0030] (3) Add water to the geopolymer precursor in step (2), the mass ratio of water and geopolymer precursor is 1:...

Embodiment 2

[0032] A preparation method of tungsten tailings base polymer:

[0033] (1) Combine tungsten tailings, fly ash and Na 2 CO 3Grind separately and pass through a 100-mesh sieve to obtain a powder with a particle size below 100 mesh. Take 100 grams of tungsten tailings powder and 40 grams of Na 2 CO 3 The powder is mixed evenly, 100 grams of fly ash powder and 40 grams of Na 2 CO 3 The powder is mixed evenly; then the tungsten tailings powder and Na 2 CO 3 The powder mixture was calcined at 900°C for 1 h, and the fly ash powder and Na 2 CO 3 The powder mixture was calcined at 1000°C for 1 hour and set aside;

[0034] (2) Put the two calcined products obtained in step (1) into a ball mill and grind them finely, pass through a 100-mesh sieve to obtain a powder with a particle size below 100 mesh, and then mix them uniformly to form a geopolymer precursor;

[0035] (3) Add water to the geopolymer precursor in step (2), the mass ratio of water and geopolymer precursor is 1:...

Embodiment 3

[0037] A preparation method of tungsten tailings base polymer:

[0038] (1) Combine tungsten tailings, fly ash and Na 2 CO 3 Grind separately and pass through a 100-mesh sieve to obtain a powder with a particle size below 100 mesh. Take 100 grams of tungsten tailings powder and 30 grams of Na 2 CO 3 The powder is mixed evenly, 100 grams of fly ash powder and 50 grams of Na 2 CO 3 The powder is mixed evenly; then the tungsten tailings powder and Na 2 CO 3 The powder mixture was calcined at 800 °C for 1 h, and the fly ash powder and Na 2 CO 3 The powder mixture was calcined at 900°C for 1 hour and set aside;

[0039] (2) Put the two calcined products obtained in step (1) into a ball mill and grind them finely, pass through a 100-mesh sieve to obtain a powder with a particle size below 100 mesh, and then mix them uniformly to form a geopolymer precursor;

[0040] (3) Add water to the geopolymer precursor in step (2), the mass ratio of water and geopolymer precursor is 1:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com