A steel plate shear wall

A technology of steel plate shear wall and inner filling plate, which is applied to walls, buildings, building components, etc., can solve the problems of strengthening the energy dissipation capacity of steel plate walls, improve mechanical performance and ductility, overcome pinching, and increase elastic stiffness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

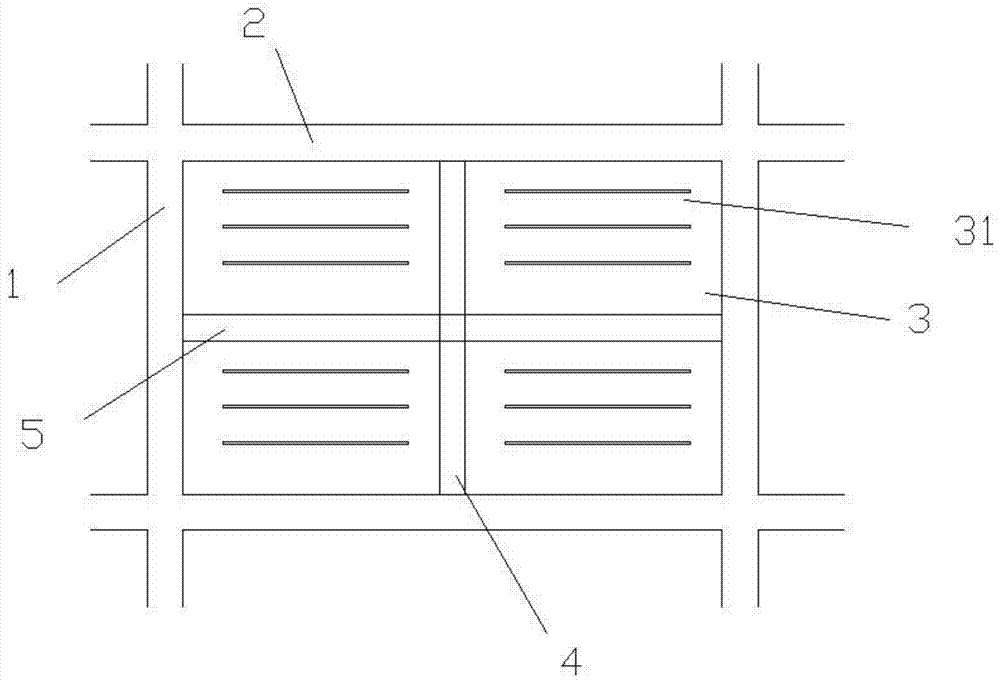

[0026] Such as image 3 As shown, a steel plate shear wall includes a peripheral column 1, a peripheral beam 2 and an inner filling plate 3. The peripheral column 1 and the surrounding beam 2 are cast and formed by a pre-concrete pouring process. The function of the inner filling plate 3 is to increase the wall The shear resistance of the body can effectively increase the strength of the shear wall. There are slits 31 on the inner filling plate 3, which can effectively convert the shear force borne by the wall into the bending stress of the inner filling plate 3, thereby effectively absorbing energy and preventing the wall from being damaged. The slit 31 is arranged horizontally, and extends from the contact position between the inner filling plate 3 and the peripheral column 1 to the inside of the inner filling plate 3. Through this arrangement, the inner filling plate 3 is divided into several leaf springs, and the horizontal setting of the spring can effectively absorb the ...

Embodiment 2

[0028] Such as figure 2 As shown, a steel plate shear wall includes a peripheral column 1, a peripheral beam 2 and an inner filling plate 3. The peripheral column 1 and the surrounding beam 2 are cast and formed by a pre-concrete pouring process. The function of the inner filling plate 3 is to increase the wall The shear resistance of the body can effectively increase the strength of the shear wall. The inner filling plate 3 is connected to the surrounding column 1, and the inner filling plate 3 is not connected to the surrounding beam 2. There are slits 31 on the inner filling plate 3, which can effectively convert the shear force borne by the wall into the bending stress of the inner filling plate 3, thereby effectively absorbing energy and preventing the wall from being damaged. The slit 31 is arranged horizontally, and extends from the contact position between the inner filling plate 3 and the peripheral column 1 to the inside of the inner filling plate 3. Through this a...

Embodiment 3

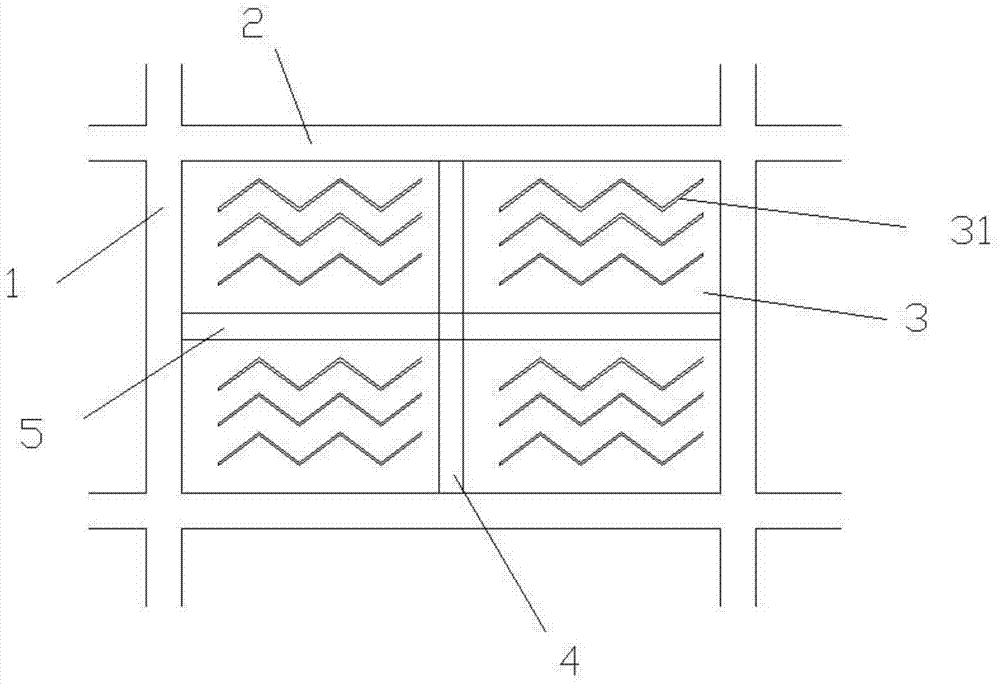

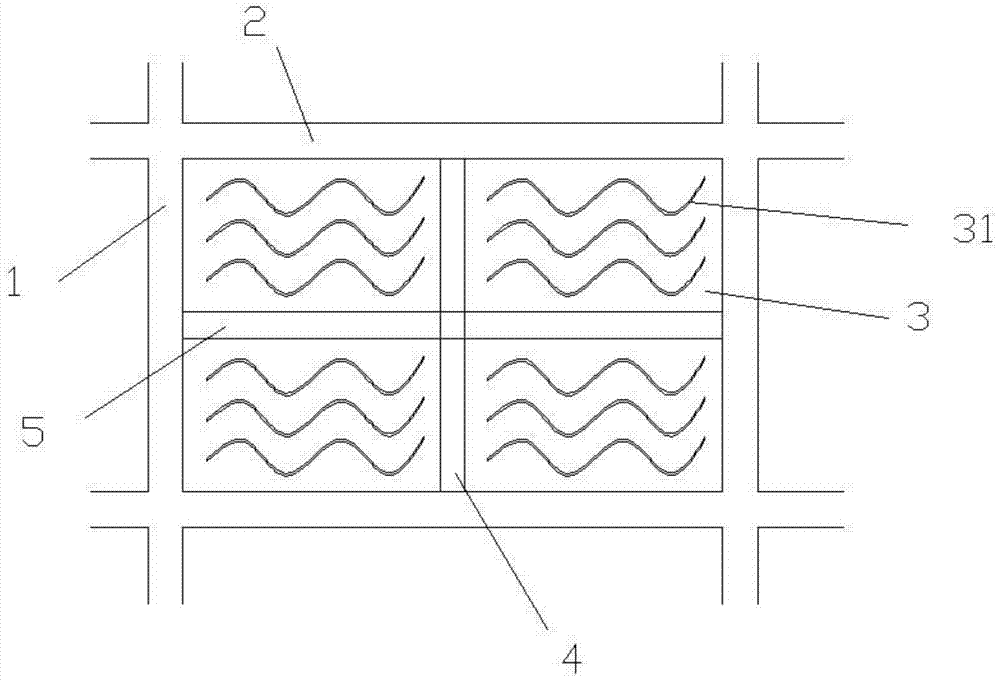

[0030] Such as Figure 4As shown, a steel plate shear wall includes a peripheral column 1, a peripheral beam 2 and an inner filling plate 3. The peripheral column 1 and the surrounding beam 2 are cast and formed by a pre-concrete pouring process. The function of the inner filling plate 3 is to increase the wall The shear resistance of the body can effectively increase the strength of the shear wall. The inner filling plate 3 is connected to the surrounding column 1, and the inner filling plate 3 is not connected to the surrounding beam 2. There are slits 31 on the inner filling plate 3, which can effectively convert the shear force borne by the wall into the bending stress of the inner filling plate 3, thereby effectively absorbing energy and preventing the wall from being damaged. The slit 31 is arranged horizontally, and extends from the contact position between the inner filling plate 3 and the peripheral column 1 to the inside of the inner filling plate 3. Through this ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com