Sound-insulation and fireproof inner wall board

A technology for sound insulation, fire prevention and interior wall panels, applied in the field of interior wall panels, can solve the problems of easy cracking at joints, inaccurate installation and positioning, poor sound insulation effect, etc., to prevent cracking at joints, ensure accuracy, and improve sound insulation. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

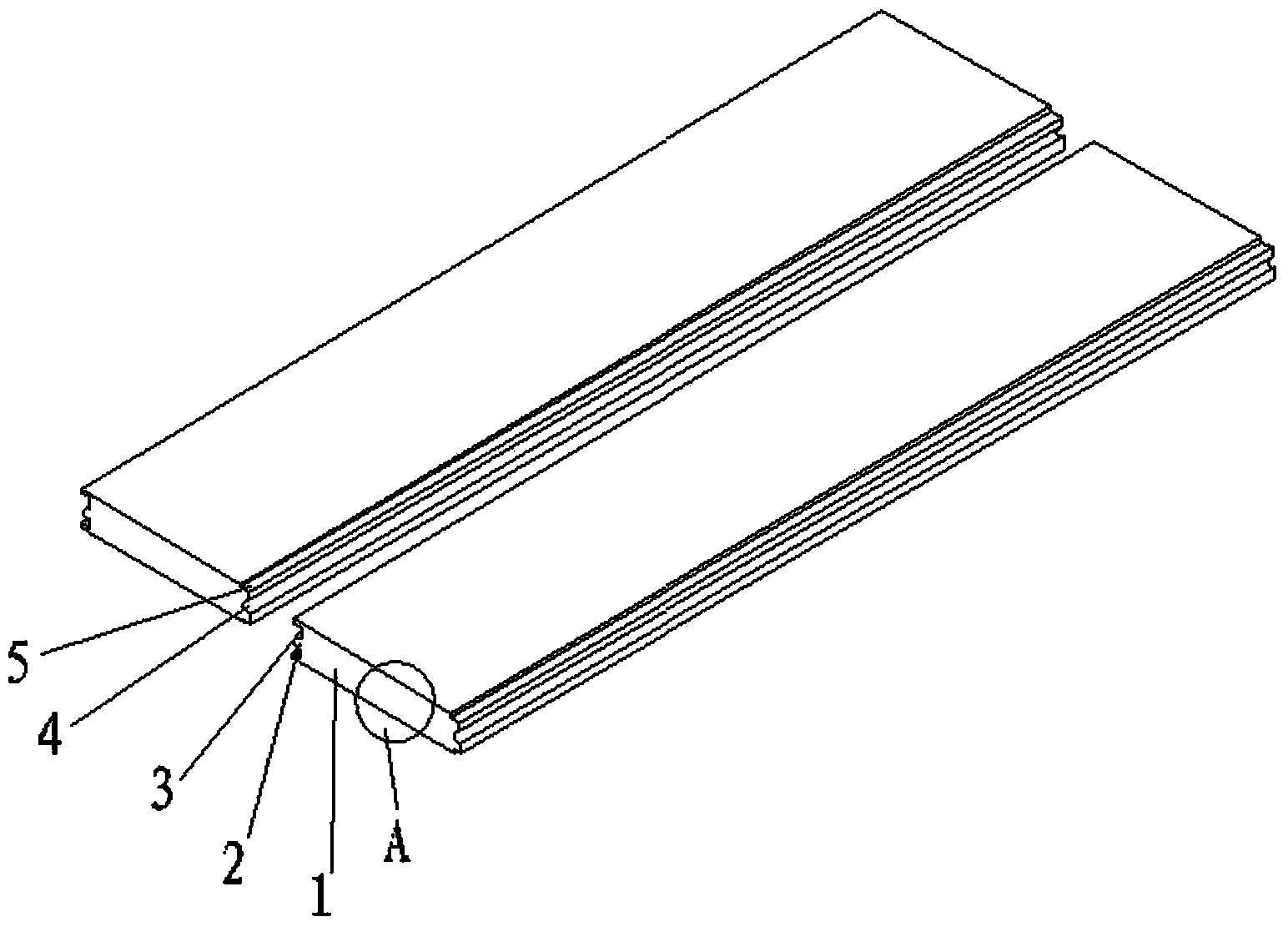

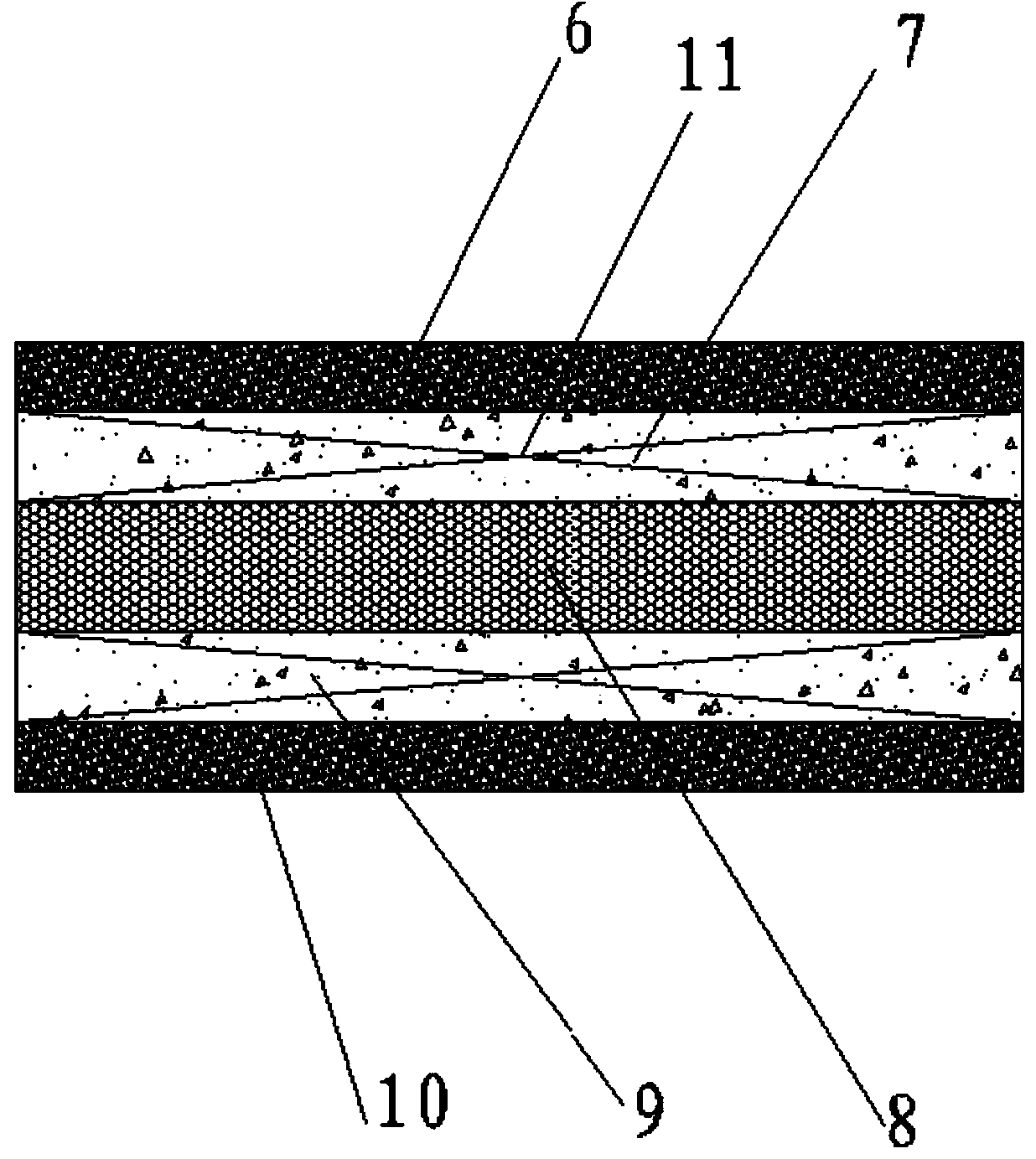

[0015] see figure 1 and figure 2 , as shown in the figure, a sound-proof and fire-proof inner wall panel, including a body 1, the body 1 is formed by bonding an upper sound-proof cement layer 7, a lightweight board 8, and a lower sound-proof cement layer 9 from top to bottom. The upper sound-insulating cement layer 7 and the lower sound-insulating cement layer 9 are formed by pouring lightweight perlite concrete. In order to strengthen its strength, a reinforcing rib 11 can be provided in the middle. The reinforcing rib 11 is composed of two steel bars of equal length cross-welded, and is fixedly installed in the upper and lower sound-proof cement layers 7 and 9, which can increase the toughness and strength of the main body 1. The lightweight board 8 is a foamed plastic board or a thin fiberboard.

[0016] The thickness of the main body 1 is 100mm to 150mm. The upper and lower surfaces of the main body 1 are coated with an upper fireproof coating 6 and a lower fireproof c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com