Interference measurement method for refractive index of lens

A technology of interferometric measurement and refractive index, which is applied in the field of optical measurement to achieve the effect of fast measurement speed and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

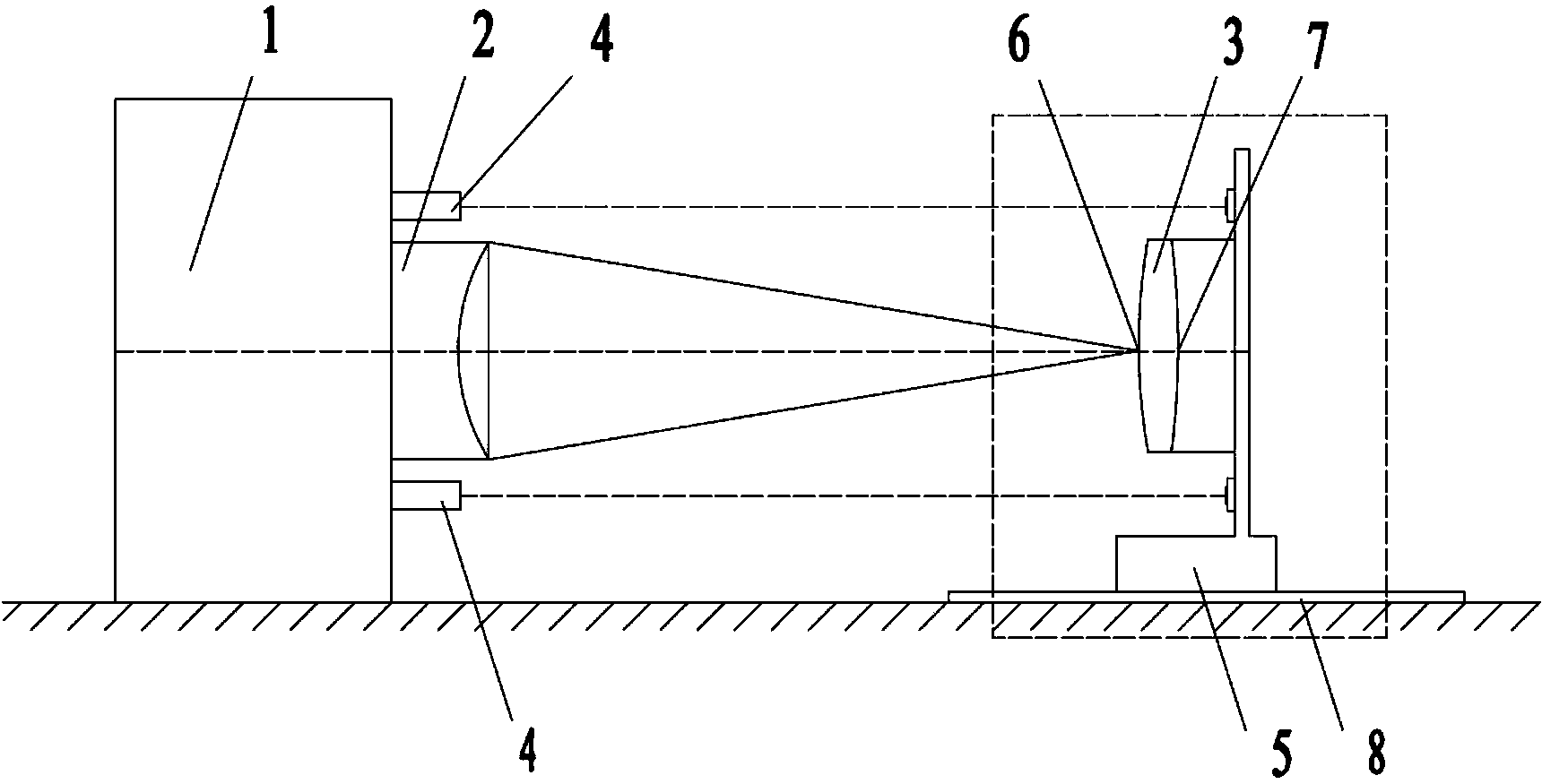

[0048] Such as figure 1 , figure 2 As shown, the concave lens refractive index interferometry method, the measurement steps are:

[0049] First, the concave lens to be measured is installed on the five-dimensional adjustment frame 5, and then the five-dimensional adjustment frame 5 is installed on the guide rail 8, and the two-way distance measuring interferometer 4 is symmetrically installed between the five-dimensional adjustment frame 5 and the interferometer 1 , adjust the measurement beam of the ranging interferometer 4 to be parallel to the guide rail 8 . The relevant parameters are known, which mainly include the radius of curvature r=423.684mm of the front surface 6 of the concave lens to be measured, the refractive index of air n 0 =1 and the center thickness of the measured concave lens 3 is d=30.6mm.

[0050] Then, turn on the interferometer 1, adjust the measured concave lens 3 to be coaxial with the standard objective lens 2, and adjust the standard objective ...

Embodiment 2

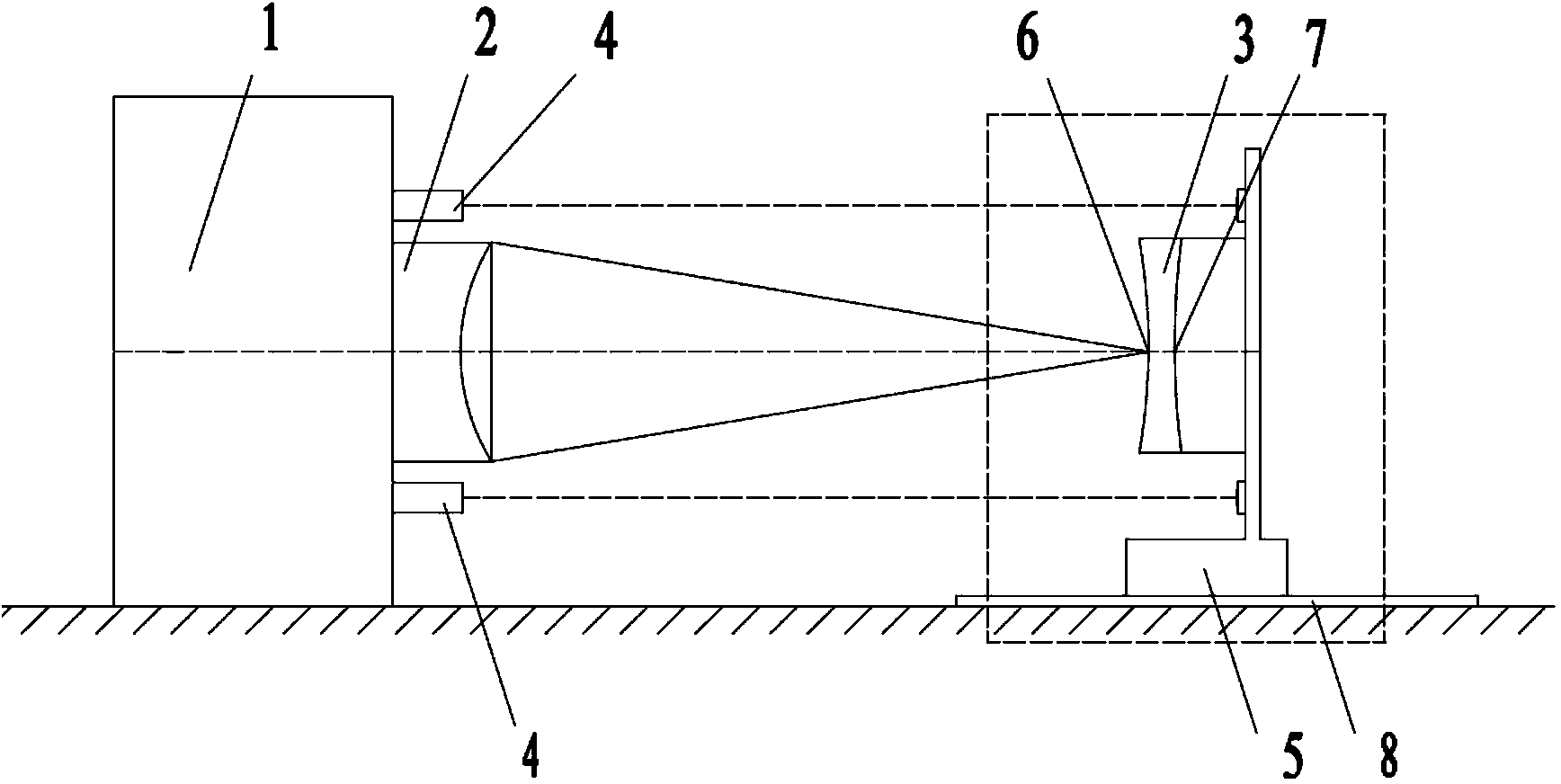

[0058] Such as figure 1 , Figure 4 As shown, the plane lens refractive index interferometry method, the measurement steps are:

[0059] First, install the measured plane lens on the five-dimensional adjustment frame 5, then install the five-dimensional adjustment frame 5 on the guide rail 8, and install two-way distance measuring interferometers symmetrically between the five-dimensional adjustment frame 5 and the interferometer 1 4. Adjust the measurement beam of the ranging interferometer 4 to be parallel to the guide rail. The relevant parameters are known, which mainly include the refractive index of air n 0 =1 and the center thickness of the measured plane lens 3 d=17.04mm.

[0060] Then, open the interferometer 1; Adjust the measured plane lens 3 to be coaxial with the standard objective lens 2, and adjust the standard objective lens 2 and the measured plane lens 3 to be perpendicular to the incident parallel light beam; known standard objective lens 2 aperture D=100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com