Preparation method of irregular cylindrical joint crack network model rock core test sample

A technology of columnar joints and fissure network, which is used in the preparation of test samples, soil material testing, material inspection products, etc. The mechanical properties of the jointed core and the inability to effectively reflect the mechanical properties of the columnar jointed rock mass have achieved the effects of simple materials, simple operation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A method for preparing an irregular columnar joint fissure network model core sample, comprising the following steps:

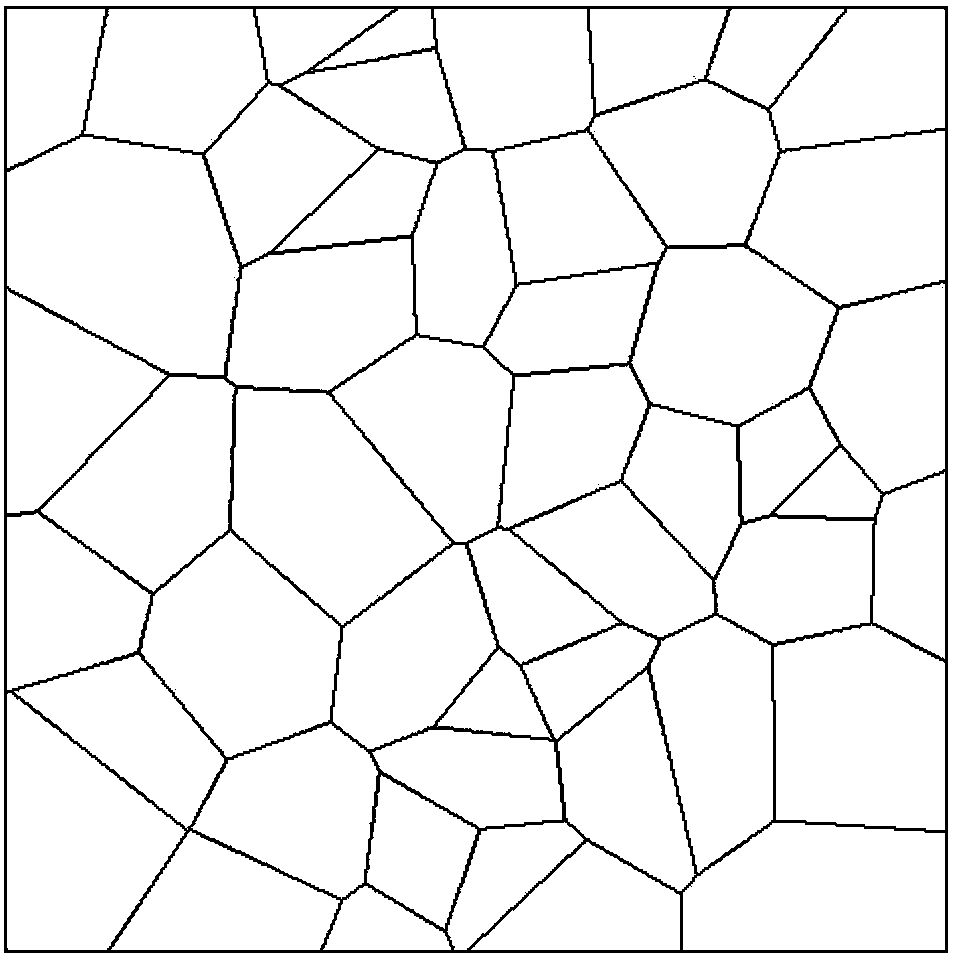

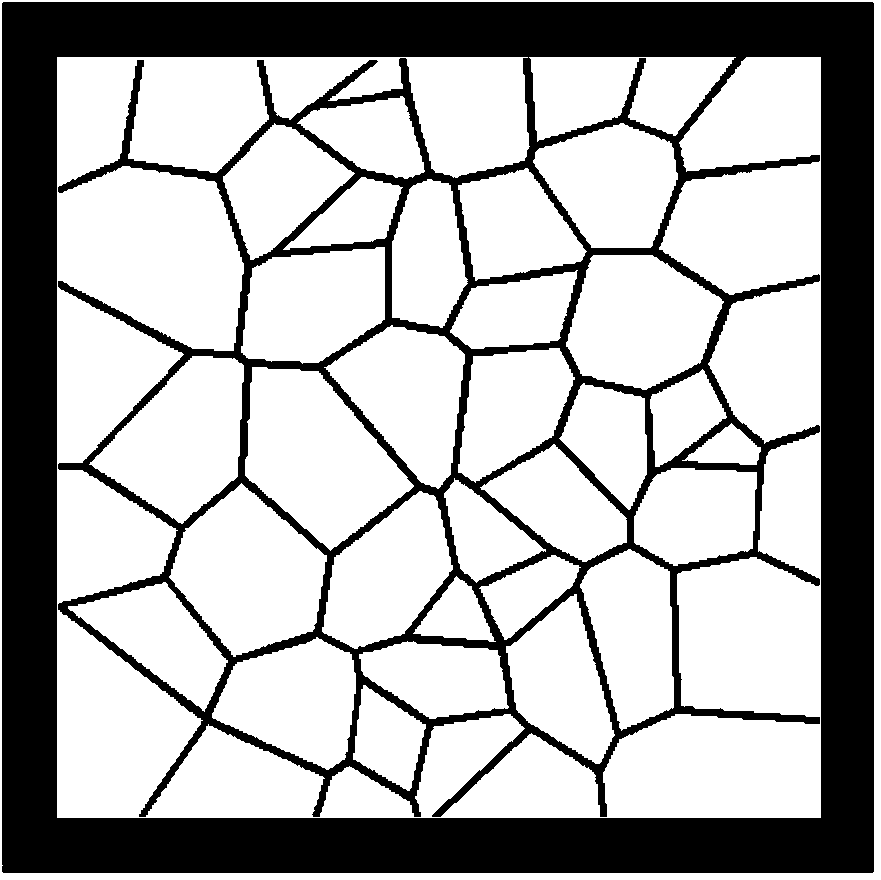

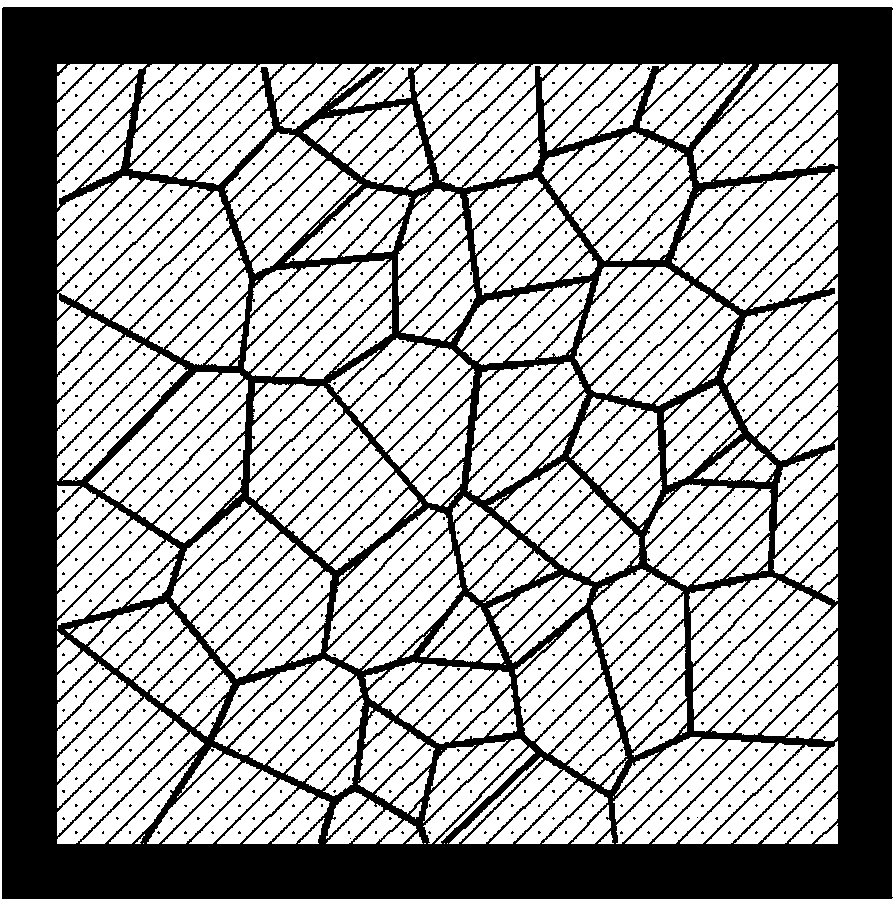

[0045] (1) Irregular voronoi graphics are generated by controlling the polygon radius and shape during the voronoi generation process. This shape is a regular quadrilateral with a side length of 70mm, such as figure 1 , expand the voronoi graph to generate a 3D random columnar joint fissure network with a height of 150mm, such as figure 2 .

[0046] (2) Use plexiglass blocks to cement together to form the 3D random columnar joint fissure network in step (1). The size of the joint fissure network shape that is generated in the step (1) obtains the size of the plexiglass block according to equal proportions, obtains the plexiglass block of fixed size by cutting large pieces of plexiglass, wherein the height of this plexiglass block is 150mm, and the thickness According to the joint fissure network in step (1), the plexiglass blocks are spliced toget...

Embodiment 2

[0056] A method for preparing an irregular columnar joint fissure network model core sample, comprising the following steps:

[0057] (1) Irregular voronoi graphics are generated by controlling the polygon radius and shape during the voronoi generation process. This shape is a regular quadrilateral with a side length of 70mm, such as figure 1 , expand the voronoi graph to generate a 3D random columnar joint fissure network with a height of 150mm, such as figure 2 .

[0058] (2) Use plexiglass blocks to cement together to form the 3D random columnar joint fissure network in step (1). The size of the joint fissure network shape that is generated in the step (1) obtains the size of the plexiglass block according to equal proportions, obtains the plexiglass block of fixed size by cutting large pieces of plexiglass, wherein the height of this plexiglass block is 150mm, and the thickness According to the joint fissure network splicing plexiglass block in step (1), thereby the ple...

Embodiment 3

[0068] A method for preparing an irregular columnar joint fissure network model core sample, comprising the following steps:

[0069] (1) Irregular voronoi graphics are generated by controlling the polygon radius and shape during the voronoi generation process. This shape is a regular quadrilateral with a side length of 70mm, such as figure 1 , expand the voronoi graph to generate a 3D random columnar joint fissure network with a height of 150mm, such as figure 2 .

[0070] (2) Use plexiglass blocks to cement together to form the 3D random columnar joint fissure network in step (1). The size of the joint fissure network shape that is generated in the step (1) obtains the size of the plexiglass block according to equal proportions, obtains the plexiglass block of fixed size by cutting large pieces of plexiglass, wherein the height of this plexiglass block is 150mm, and the thickness According to the joint fissure network splicing plexiglass block in step (1), thereby the ple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com