Reactor core of medical isotope production reactor

An isotope and core technology, applied in the core field of medical isotope production reactors, can solve the problems of unfavorable solution sealing and containment, unusable material liquid, etc., and achieve the effect of avoiding accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0018] Take the 200kW designed core as an example:

[0019] 1. Core description

[0020] The specific parameters of the core are as follows:

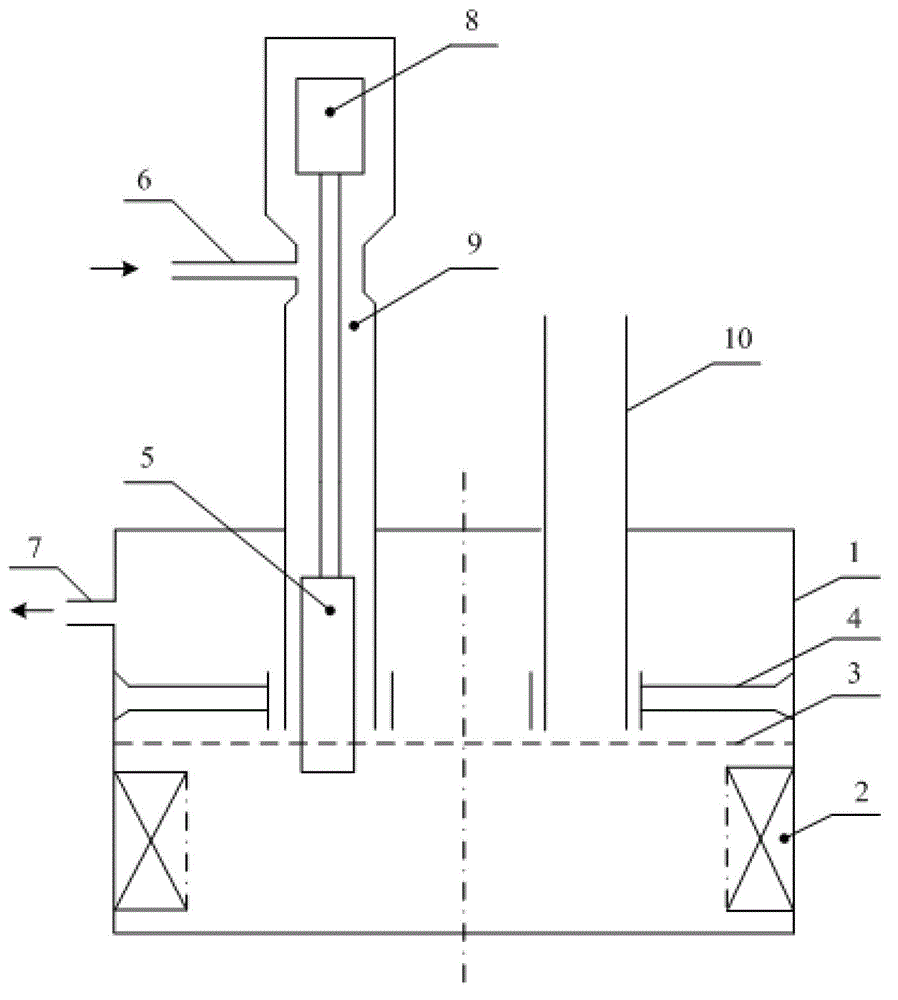

[0021] 1). Stacking container 1. The size of the cylinder is φ720×10mm, and the flat bottom stacking container is made of 304L or 316L stainless steel;

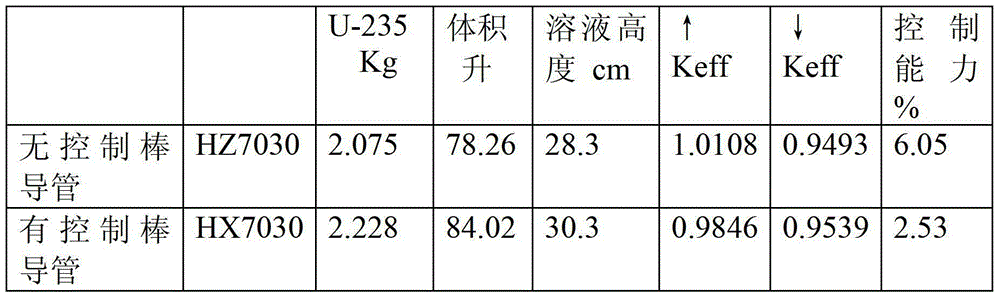

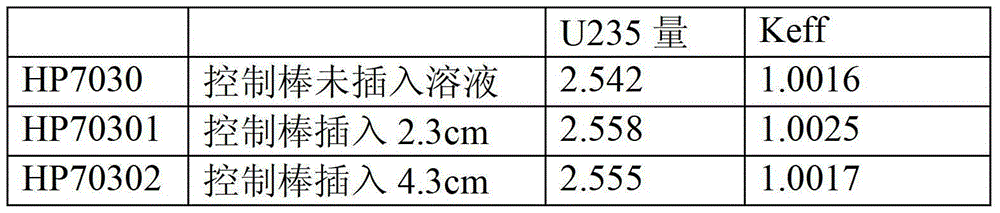

[0022] 2).With control rod catheter

[0023] There are 6 control rod conduits 10 in total, the size is φ37×1.5mm, and the material is 304L or 316L. The size of the control rod 5 is φ32mm, the material of the control rod 5 is 304L or 316L stainless steel, and the material of the follower is graphite, and they are evenly arranged on the circumference of φ190mm superior;

[0024] 3).No control rod catheter

[0025] There are 6 control rods 5, the size of the control rods 5 is φ32mm, the material of the control rods 5 is 304L or 316L stainless steel, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com