Lead structure of triangular iron roll core transformer

A technology of transformer and coiled iron core, which is applied in the field of lead wire structure of triangular coiled iron core transformer, which can solve the problems of large difference in copper bar length and excessive DC resistance unbalance rate of transformer winding, etc., so as to reduce consumption and improve DC resistance The effect of unbalance rate and saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

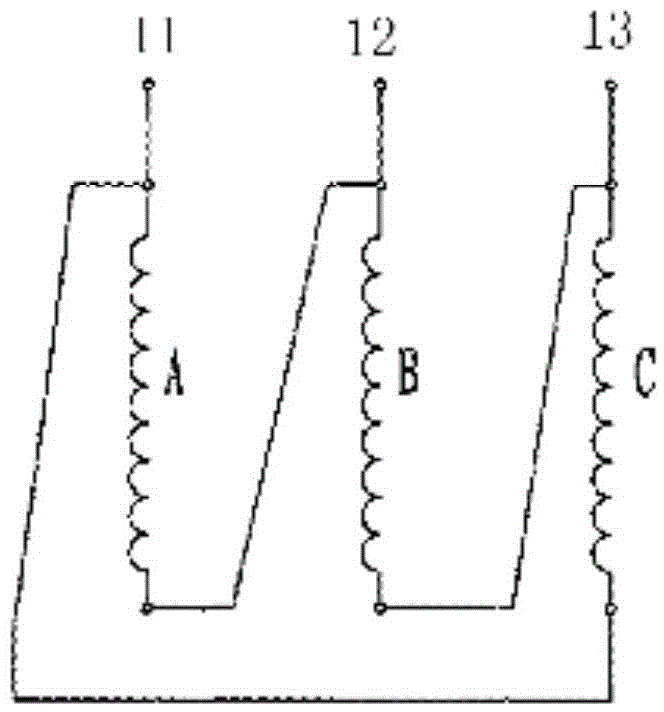

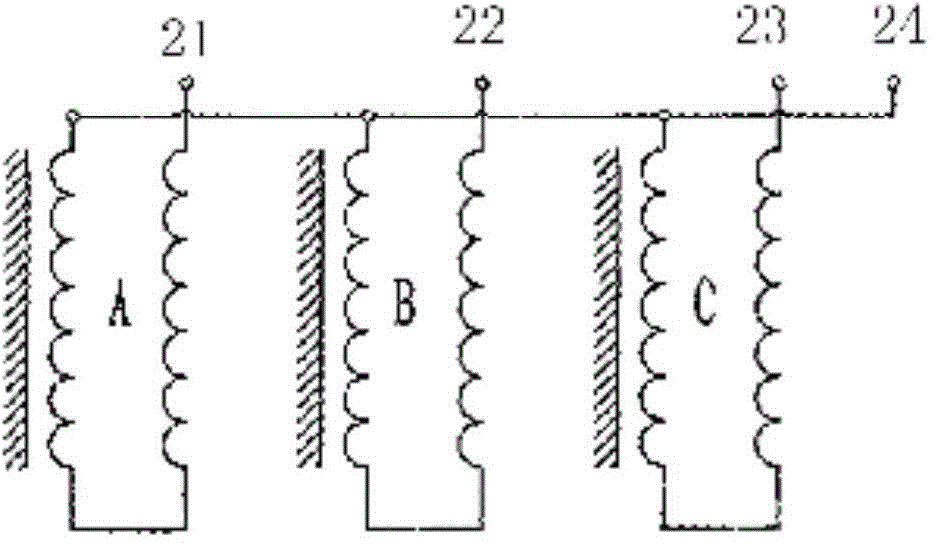

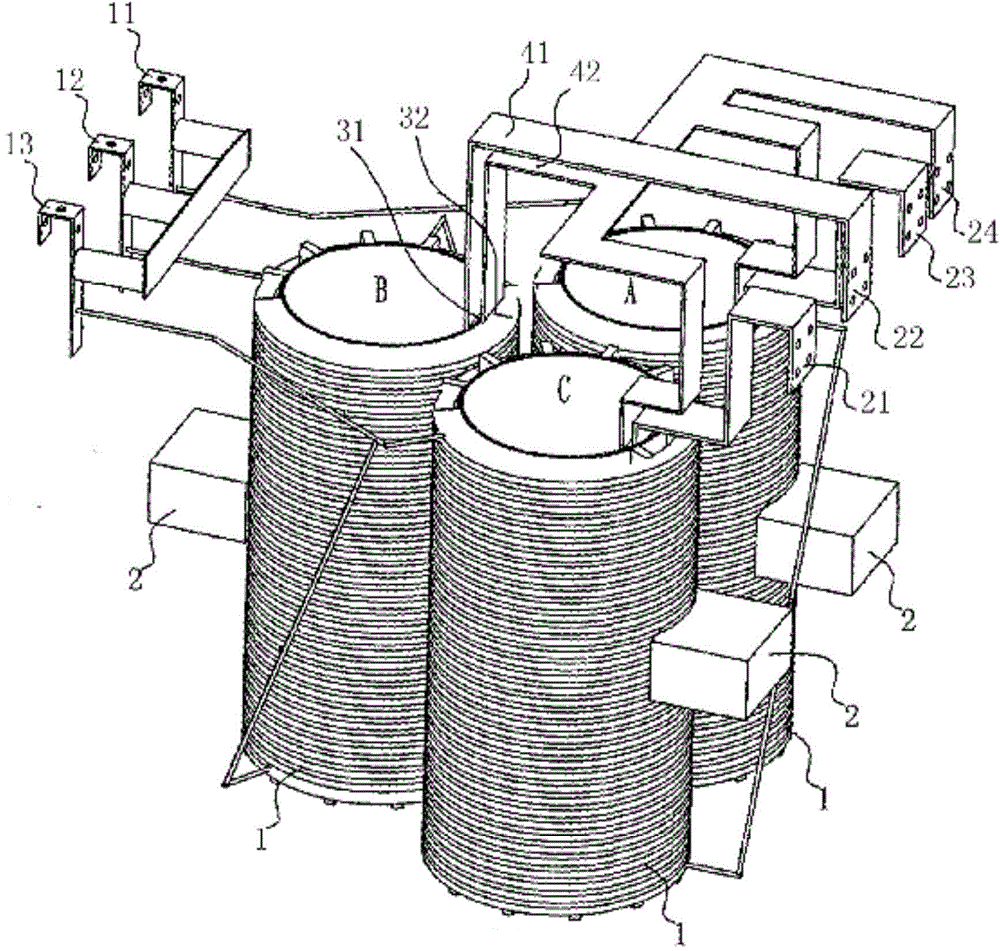

[0012] Such as figure 1 , 2 , 3, a lead wire structure of a triangular wound iron core transformer, the three-phase windings A, B, and C of the transformer are respectively composed of primary windings and secondary windings, and the transformer is facing the one-phase winding B One end of the transformer is provided with the primary winding terminals 11, 12, 13, and the secondary winding terminals 21, 22, 23, 24. The phase-to-phase taps of the windings A, B, and C of each phase are connected, and the lead wire taps of the windings A, B, and C of each phase are respectively connected to the corresponding terminals through copper bars, and are adjacent to the primary winding terminals 11, The two secondary winding lead taps 31, 32 of the winding B of 12, 13 are all arranged on the side of the phase winding away from the primary winding terminals 11, 12, 13, and the two secondary winding lead taps 31, 32 are connected to The connecting copper bars 41 and 42 of the correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com