A circuit breaker operating mechanism energy storage tripping mechanism

A technology of an operating mechanism and a tripping mechanism, which is applied in the protection switch operation/release mechanism and other directions, can solve the problems of high production cost, inconvenient manufacturing, and high machining accuracy of the energy storage mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

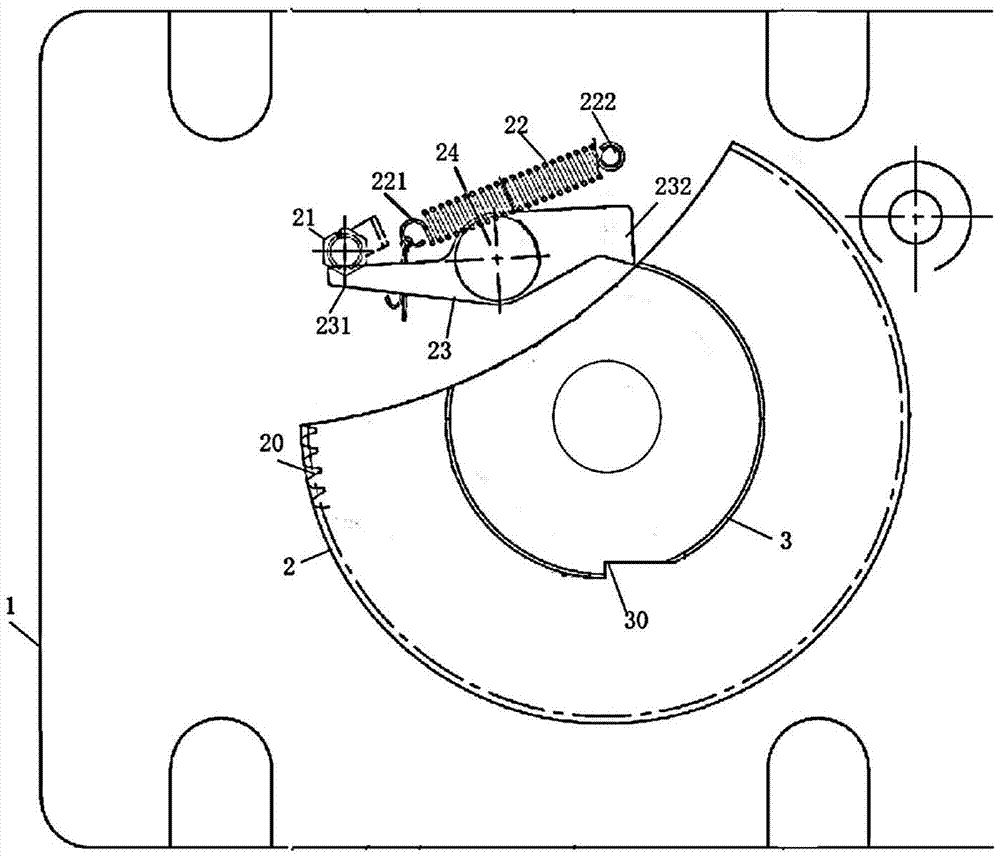

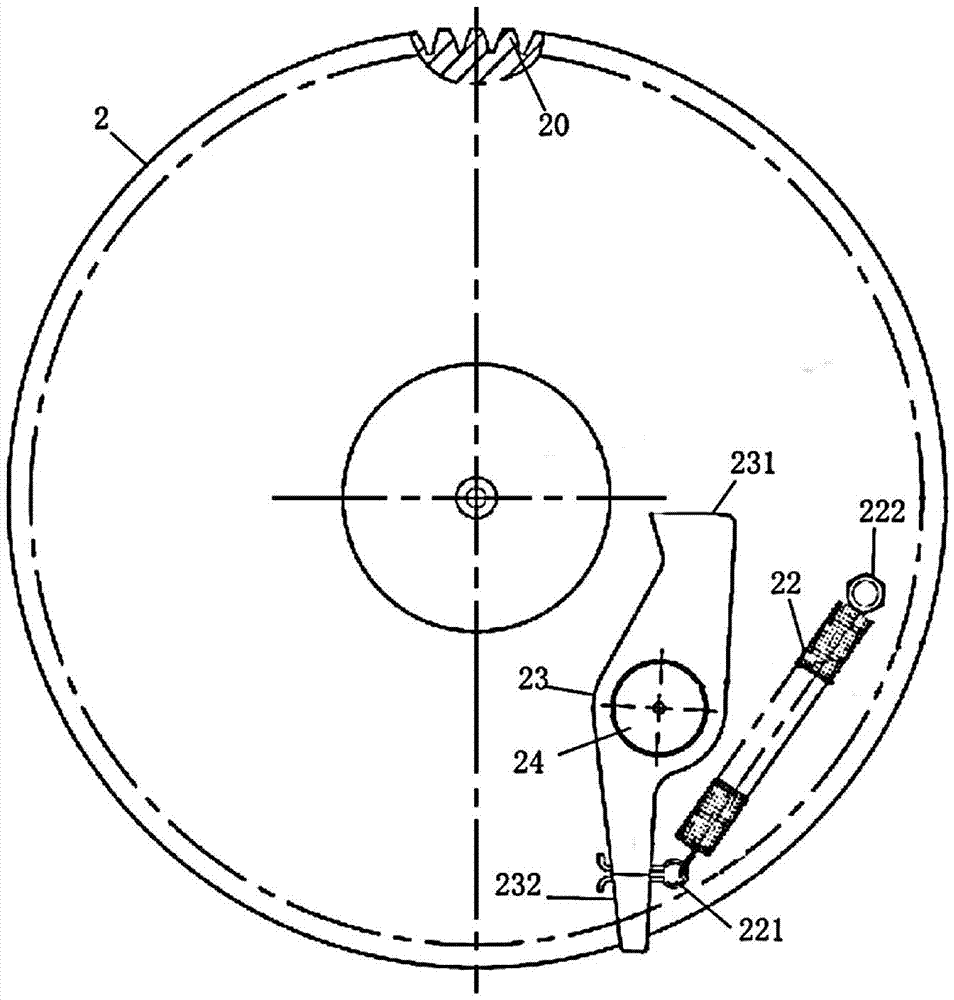

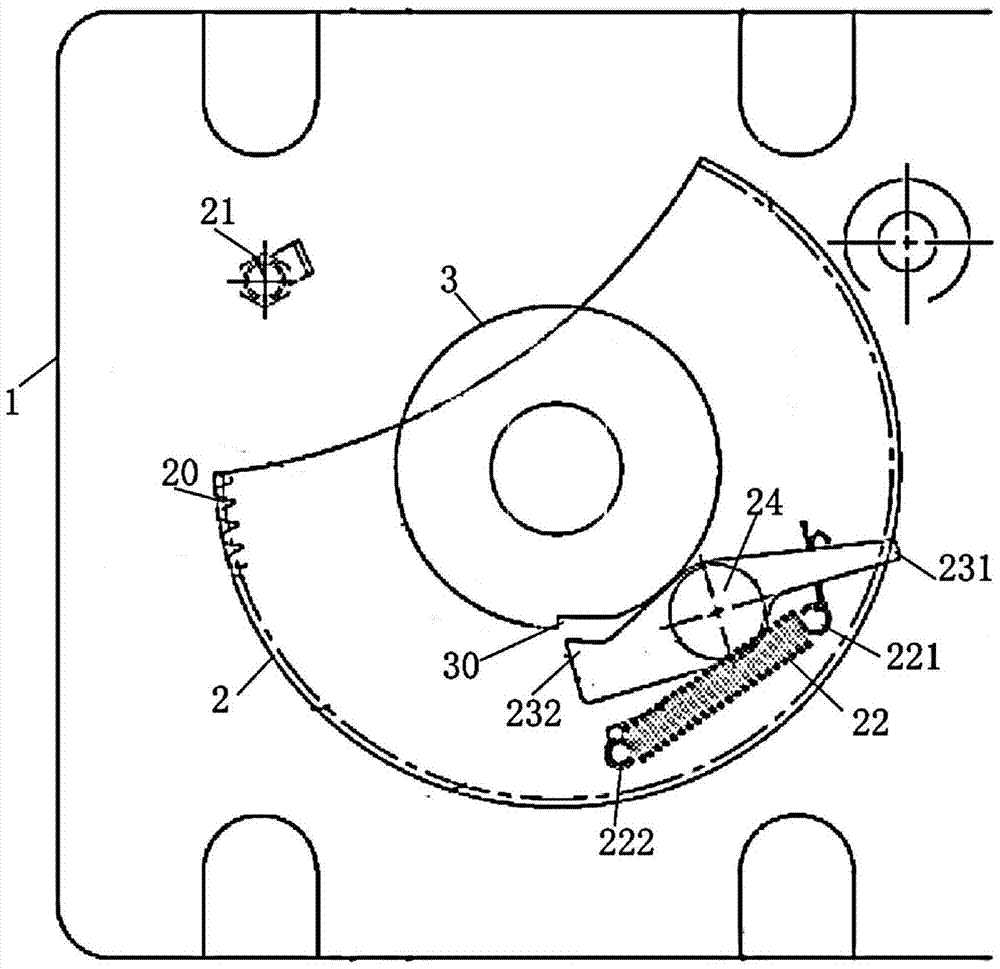

[0016] An embodiment of a circuit breaker operating mechanism energy storage tripping mechanism of the present invention: as Figure 1-6 As shown, it includes a fixed base 1, the fixed base 1 is provided with a motor and a power input shaft and an energy storage shaft 4 connected to the output end of the motor, the power input shaft transmits torque to the energy storage shaft 4, and the energy storage shaft The end of 4 is provided with the energy storage crank arm 5 that is connected with the energy storage spring and is used for energy storage, and the power input shaft and the energy storage shaft 4 are coaxial and are assembled on the fixed base 1 around its axis, and the power input shaft and the energy storage shaft 4 are coaxial. The energy storage shaft 4 is perpendicular to the fixed base 1, and the power input shaft is coaxially fixed with a rotating disk 2. The outer peripheral edge of the rotating disk 2 is provided with gear teeth 20 for transmission connection wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com