Heat transfer pipe for fin-and-tube type heat exchanger, and fin-and-tube type heat exchanger

A technology of finned tube type and heat exchanger, which is applied in the direction of indirect heat exchanger, heat exchanger type, evaporator/condenser, etc., can solve the problem of triangular heat transfer tube thermal conductivity without any research, and it is difficult to form the target triangular shape Holes, metal flow, etc., to achieve the effect of lightweight manufacturing cost, increased area, and improved thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0050] Hereinafter, representative examples of the present invention will be shown to clarify the present invention more specifically, but the present invention is of course not limited in any way by the description of such examples.

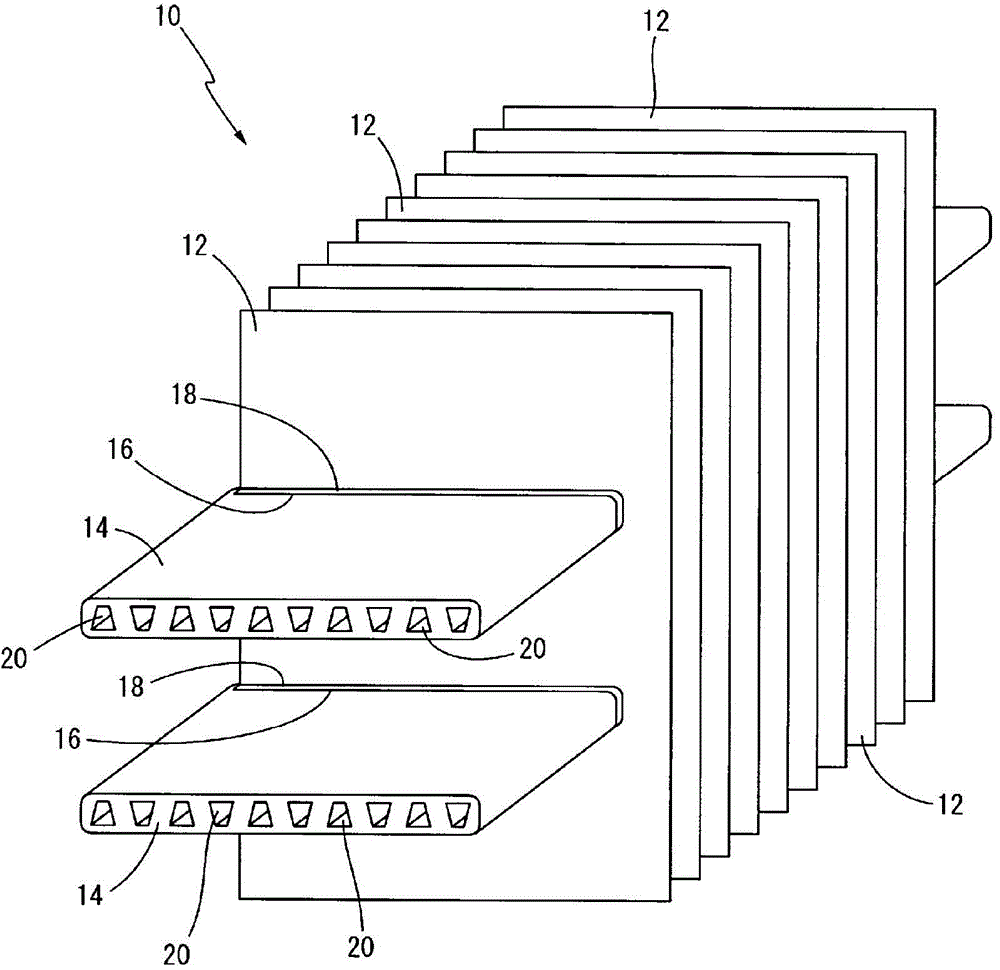

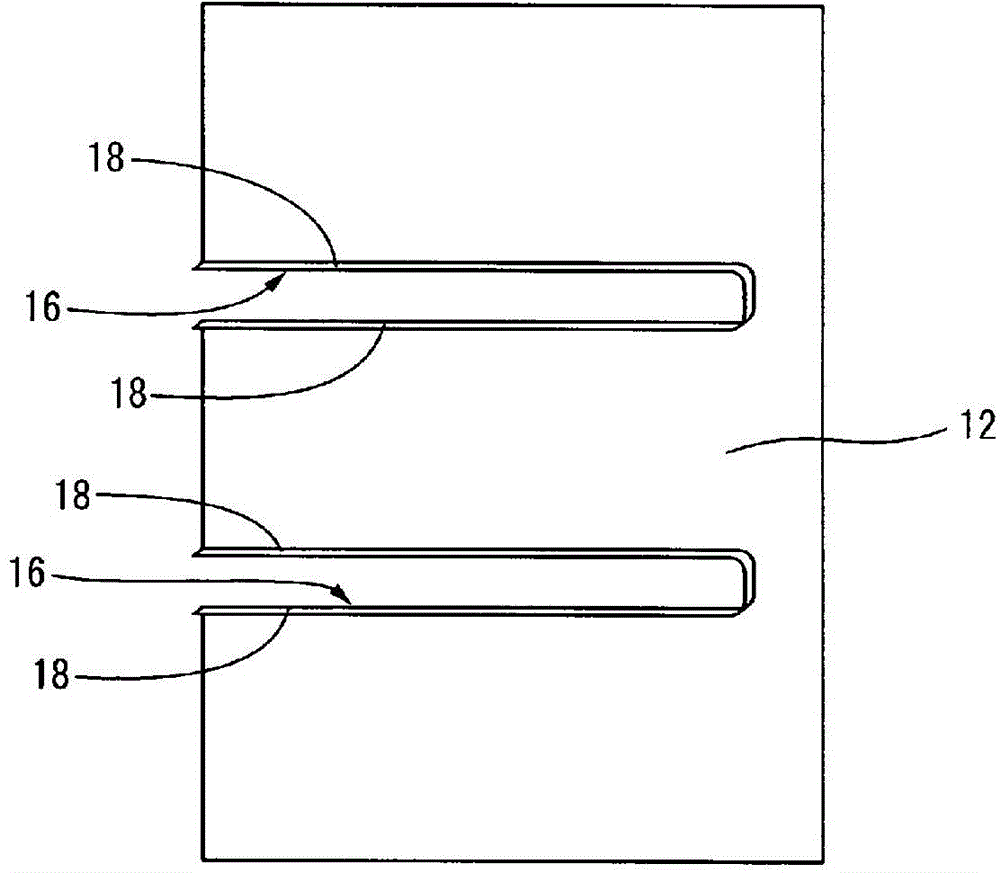

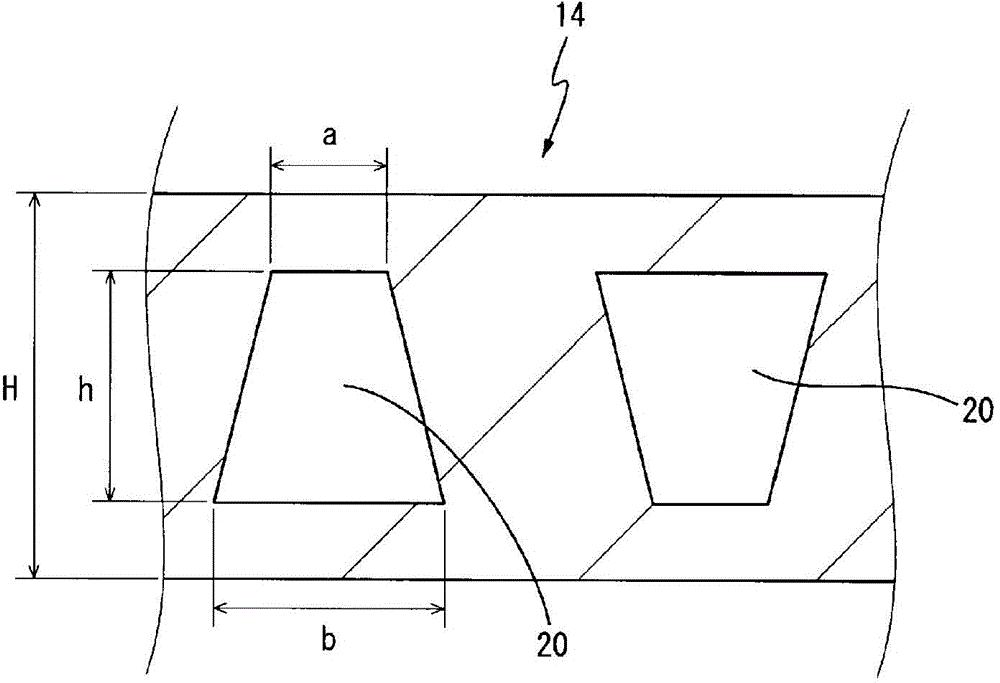

[0051] First, as a heat transfer tube for a finned tube heat exchanger according to the present invention, an aluminum alloy (Japanese Industrial Standard JISA3003) is extruded to prepare the following: Figure 5 An extruded flat porous tube 40 having a cross-sectional shape as shown in (a) with a width W of 16 mm, a thickness H of 1.9 mm, and a number of holes of 12 was used as heat transfer tube No. 1. The shape of the 12 holes 42 provided in this heat transfer tube No. 1 is an isosceles trapezoid with an upper base a of 0.6 mm, a lower base b of 1.2 mm, and a height h of 1.2 mm (0.63 times the thickness of the heat transfer tube). . In addition, various parameters such as the hydraulic diameter are shown in Table 1 below. In addition, in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com