Sizing mould for flower tea of golden camellia for electrostatic field drying

A technology of electrostatic field drying and mold shaping, applied in the direction of tea substitutes, etc., can solve the problems of golden camellia tea loss of color, low production efficiency, slow drying speed of cold air, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

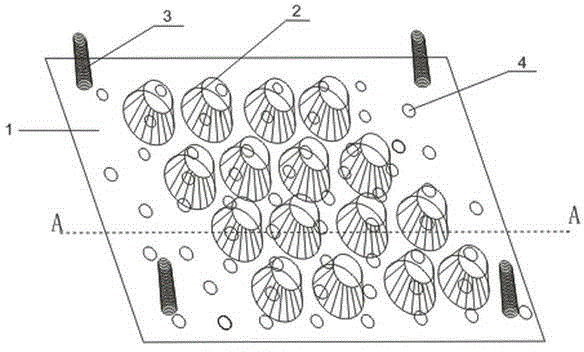

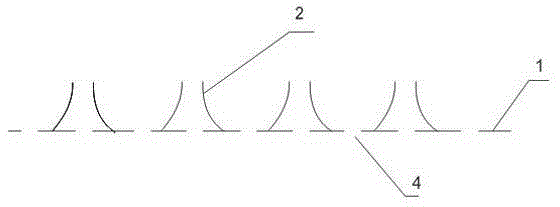

[0011] Such as figure 1 , image 3 As shown, the shaping mold of camellia japonica flower tea that can be used in an electrostatic field is composed of a tray 1, a shaping cylinder 2, and a pillar 3. The tray 1 is provided with a plurality of through holes 4, and the shaping cylinder 2 is welded on the upper surface of the tray. It is an ancient round bell-shaped structure, and the pillars 3 are welded around the pallet, so that multiple pallets (1) can be used in overlapping combinations. The above-mentioned pallets, pillars, and shaping cylinders are made of metal materials that can be used for electrostatic field drying.

Embodiment 2

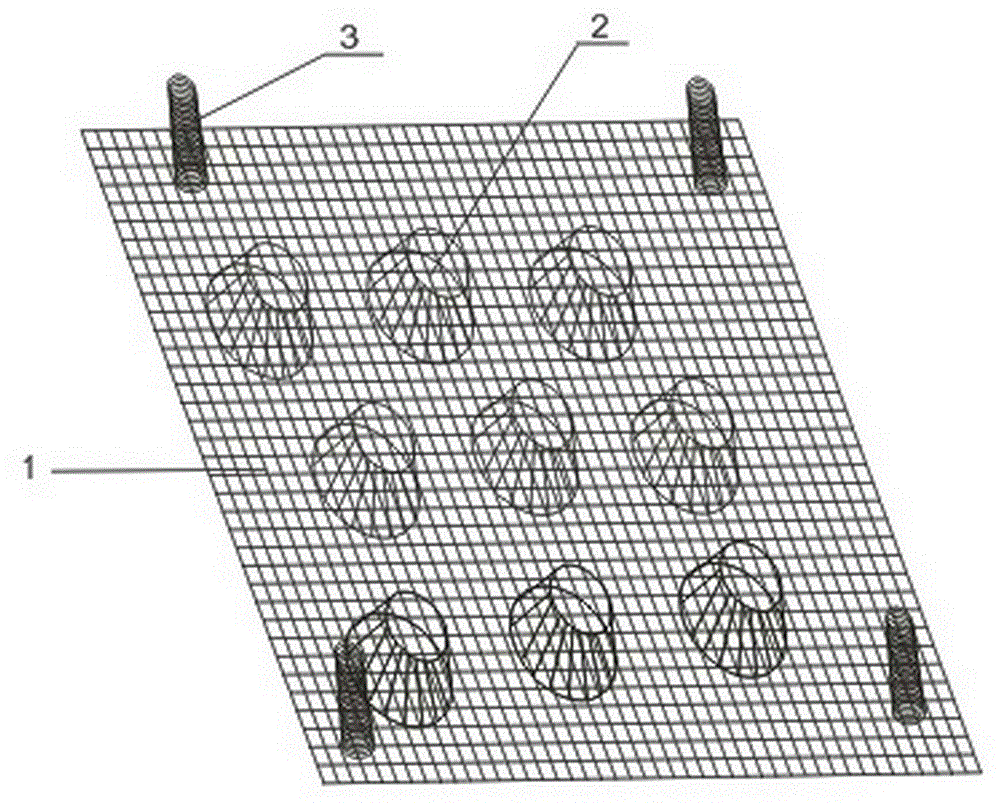

[0013] Such as figure 2 The golden camellia flower tea shaping mold that can be used in an electrostatic field is composed of a supporting net 1, a shaping cylinder 2, and a pillar 3. The shaping cylinder is welded on the upper surface of the supporting mesh 1. The shaping cylinder 2 is an ancient round bell-shaped structure, and the pillars are welded on the Around the supporting net, multiple supporting nets (1) can be overlapped and combined for use, and the above-mentioned supporting net, pillars, and shaping cylinder materials are selected from metal materials that can be used for electrostatic field drying.

[0014] When the present invention is applied, the flower buds of Camellia japonica can be placed downwards in the shaping tube 2, the petals are attached to the outside of the shaping tube 2, and the shaping tube 2 supports the flowers of Camellia japonica, so as to prevent the deformation of the petals of the flowers and keep the shape of the flowers intact beaut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com