Knife face abrasion detecting method and device

A detection device and knife surface technology, applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., to achieve the effect of convenient use and accurate measurement method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Further illustrate the present invention below in conjunction with accompanying drawing.

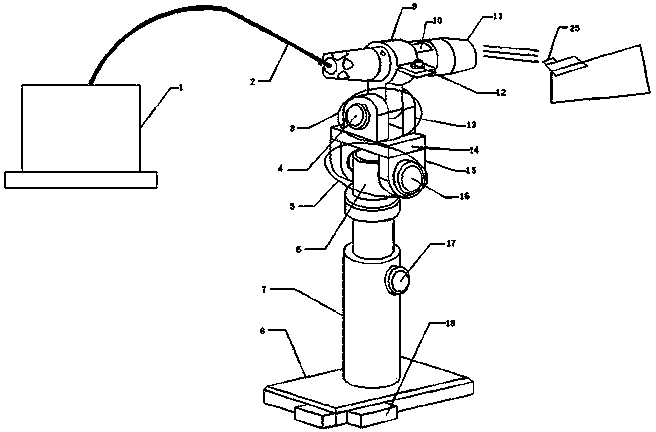

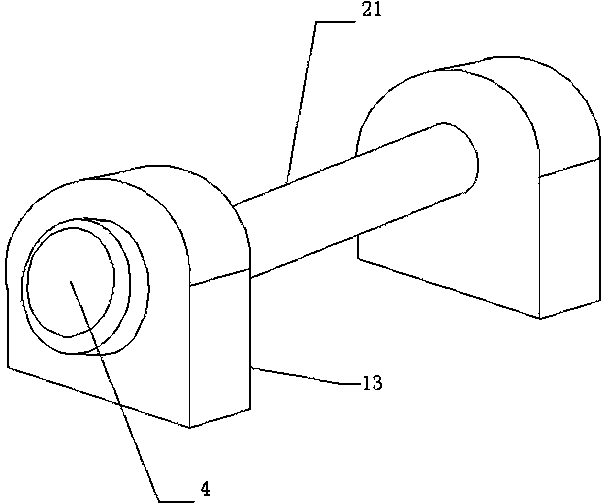

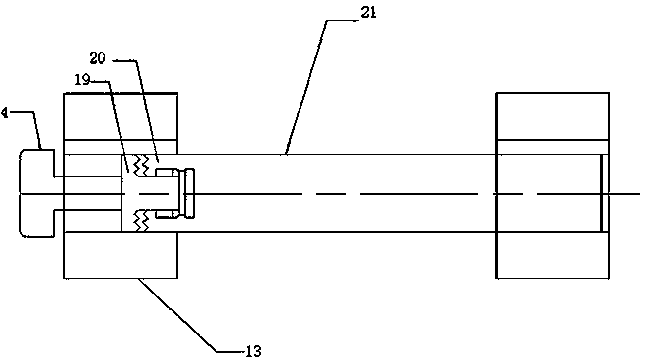

[0020] A knife surface wear detection device, including a computer 1, a USB connection line 2, a first lockable device 3, a first lockable button 4, a second lockable device 5, an inner rod 6, an outer cylinder 7, and a base 8. Microscope camera fixing ring 9, focusing knob 10, microscope camera 11, bolt 12, first support block 13, horizontal support platform 14, second support block 15, second lockable button 16, vertical knob 17, Positioning block 18, the first outer toothed disc 19, the first inner toothed disc 20, the first connecting rod 21, the second connecting rod 22, the second inner toothed disc 23, the second outer toothed disc 24 and the scale plate 25, the Described USB connection line 2 is installed on the rear end of microscope camera 11, and USB connection line 2 is connected to computer 1, and microscope camera 11 is installed in the microscope camera fixing ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com