A method for obtaining carbon black microscopic morphology enlarged entity by 3D printing

A technology of microscopic morphology and 3D printing, which is applied in the field of carbon black microscopic morphology into macroscopic entities, can solve problems that no one has raised, and achieve the effect of precise entity structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

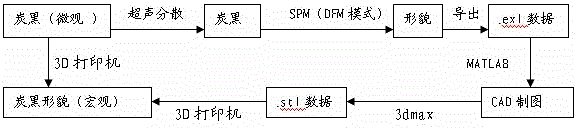

[0052]In this experiment, the carbon black was first dispersed by ultrasound, so that the carbon black particles reached the level of primary particles and aggregates, and the carbon black morphology was scanned with Hitachi E-sweep scanning probe to obtain the carbon black morphology map. Then use the software that comes with the scanning probe atomic force microscope to export the topography map, and the data is in .exl format. The .exl data is processed by MATLAB software and converted into a specific format. Then import the data into CAD, draw the shape of carbon black, and then convert it into a solid (.dwg file), and convert the data into a .stl format that can be recognized by the 3D printer through 3dmax. Finally, a magnified entity of the carbon black's microscopic topography is printed. The specific process is as figure 1 shown.

[0053] As an optional way, in the above method, the 3D printing is carried out at room temperature, and the material used is photosensi...

Embodiment 2

[0055] The microscopic morphology enlarged entities of carbon black were prepared according to the following steps:

[0056] 1) Disperse carbon black in absolute ethanol by ultrasonic (0.1mg carbon black, 200ml absolute ethanol), ultrasonic 20min;

[0057] 2) Drop the sonicated carbon black anhydrous ethanol solution on the clean mica sheet and dry it. Put the mica sheet into the sample chamber of the scanning probe microscope and scan it to obtain the microscopic topography of carbon black (nanoscale);

[0058] 3) Convert the microscopic morphology of carbon black from .xqd to .xqt, and then export the .exl data (256×256 points);

[0059] 4) Use MATLAB software to develop a program to process the .exl data:

[0060] clear

[0061] clc;

[0062] mm=xlsread('dat.xlsx');

[0063] mn=size(mm);

[0064] k=1;

[0065] for i=1:1:mn(1)

[0066] for j=1:1:mn(2)

[0067] xx(k,:)=[mm(1,j),mm(i,1),mm(i,j)];

[0068] k=k+1;

[0069] end

[0070] end

[0071] xlswrite('sj.xlsx...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com