A Nozzle Diaphragm Structure for Reducing the Exciting Force of Low-Frequency Air Flow in the Regulating Stage of Turbomachinery

A technology of airflow excitation force and nozzle baffle, which is applied in the direction of mechanical equipment, engine components, machines/engines, etc., can solve the problems of large airflow excitation force of moving blades and uneven airflow, so as to improve airflow force load and reduce The effect of changing amplitude and reliable technical support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] Before introducing the present invention, it is necessary to briefly introduce the structure of the conventional nozzle baffle and the mechanism of low-frequency exciting force generated by part of the inlet steam turbine machinery, which is helpful for the understanding of the present invention.

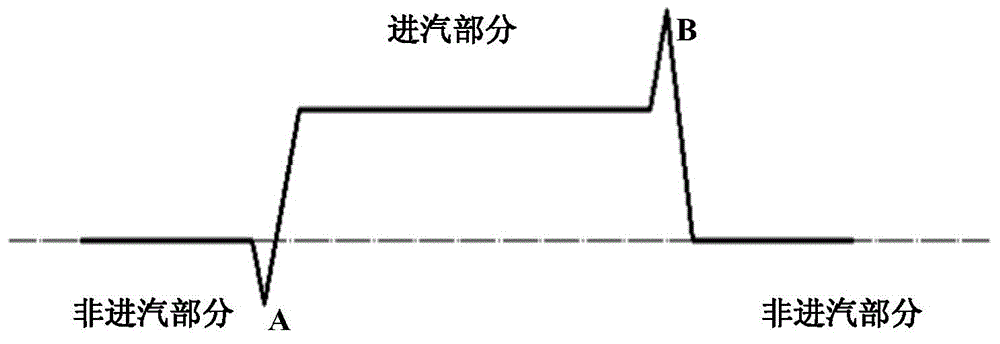

[0018] see figure 1 , is a schematic diagram of the structure of a conventional nozzle diaphragm. The interface between the non-steam inlet section and the steam inlet section is a straight line, and the airflow force on the moving blade completes the transition from the steam inlet section to the non-steam inlet section or from the non-steam inlet section to the steam inlet section in a relatively short period of time.

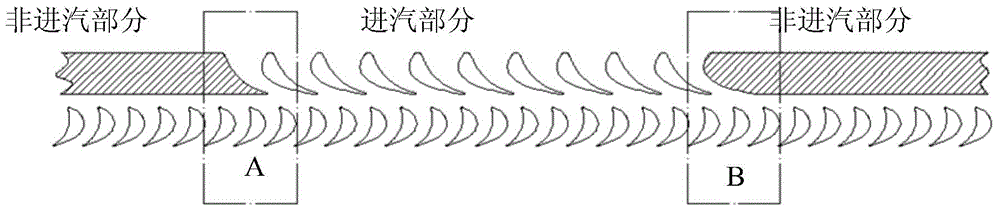

[0019] see figure 2 , is a schematic diagram of part of the inlet steam turbomachinery. The moving blade rotates in the circumferential directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com