Centrifugal fan for high-efficiency, low-noise, ultra-high specific speed motor

A high specific speed, centrifugal fan technology, used in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of inability to meet the requirements of motor performance indicators, inability to meet motor performance requirements, inconvenient installation and maintenance, etc. Compact, error-free, excellent aerodynamic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

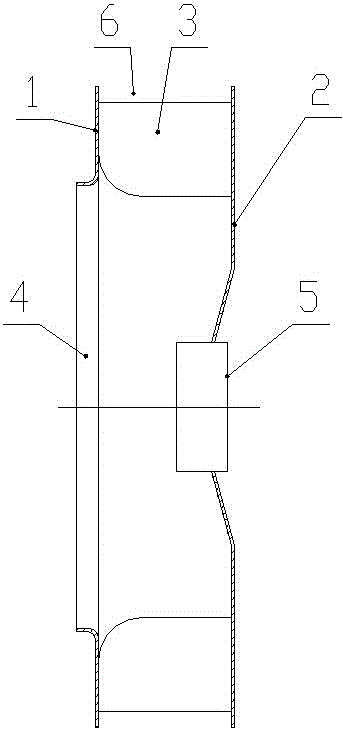

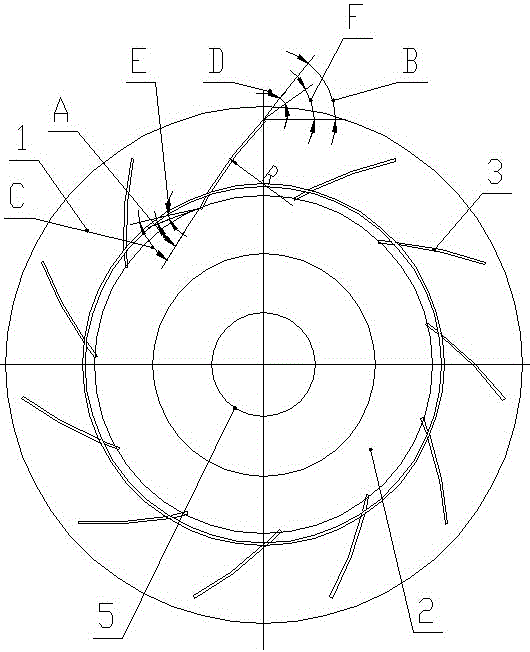

[0013] like figure 1 and figure 2 As shown, the centrifugal fan for a high-efficiency, low-noise, and extra-high specific speed motor of the present invention includes a front cover 1, a rear cover 2 and a fan blade 3, and the front cover 1 and the rear cover 2 are correspondingly provided with slot holes in the front and rear. , a number of slot holes are arranged correspondingly and evenly along the circumferential direction of the front cover 1 and the rear cover 2, and the fan blades 3 are arranged between the corresponding slots of the front cover 1 and the rear cover 2. The middle of the front cover 1 It is the air inlet 4, the outer peripheral edge between the front cover 1 and the rear cover 2 is the air outlet 6, and the middle of the rear cover 2 is provided with a shaft sleeve 5; the single arc airfoil radius R of the fan blade 3 is 250-300mm , the fan blade 3 inlet installation angle A is 20-25°, the fan blade 3 outlet installation angle B is 15-20°, the airflow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com