Double vane shaft universal coupling

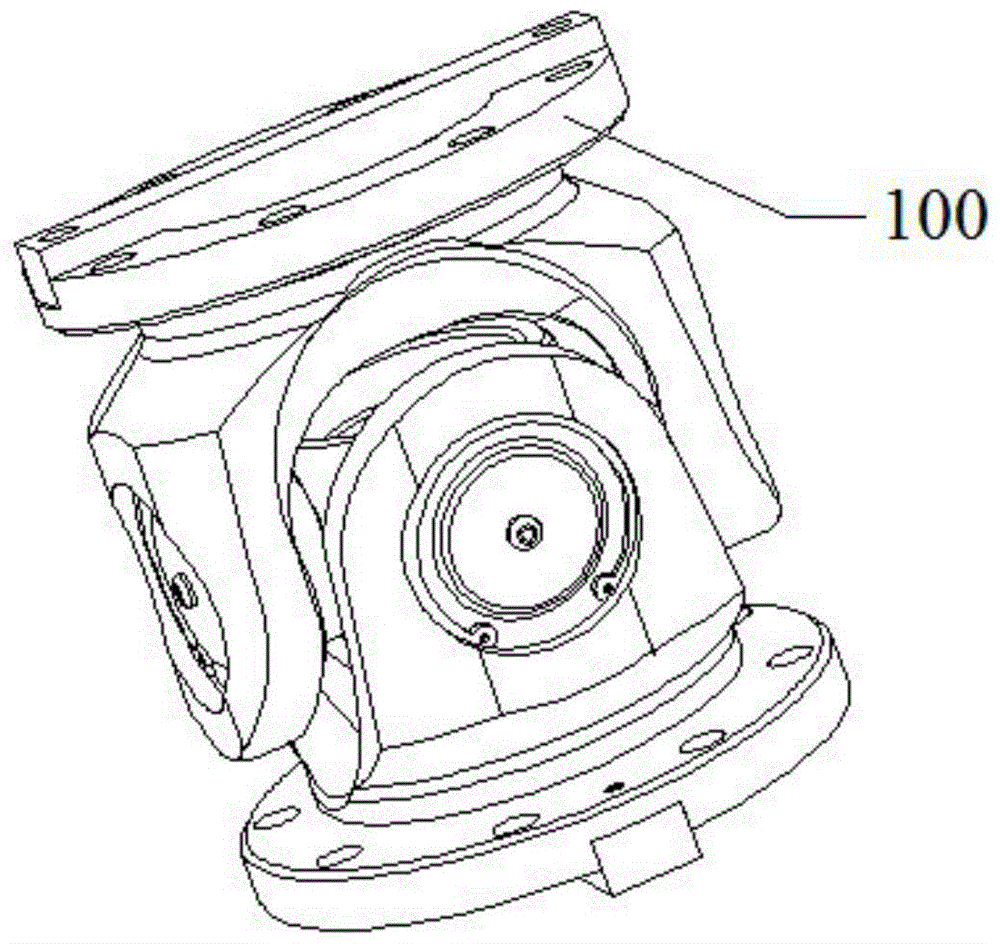

A universal coupling and shaft-type technology, which is applied in the direction of couplings, elastic couplings, mechanical equipment, etc., can solve the problems of reducing the strength of the flange yoke, breaking the cross shaft, and cracking the circlip, so as to avoid cracking or fall off, increase the carrying capacity, and improve the reliability of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

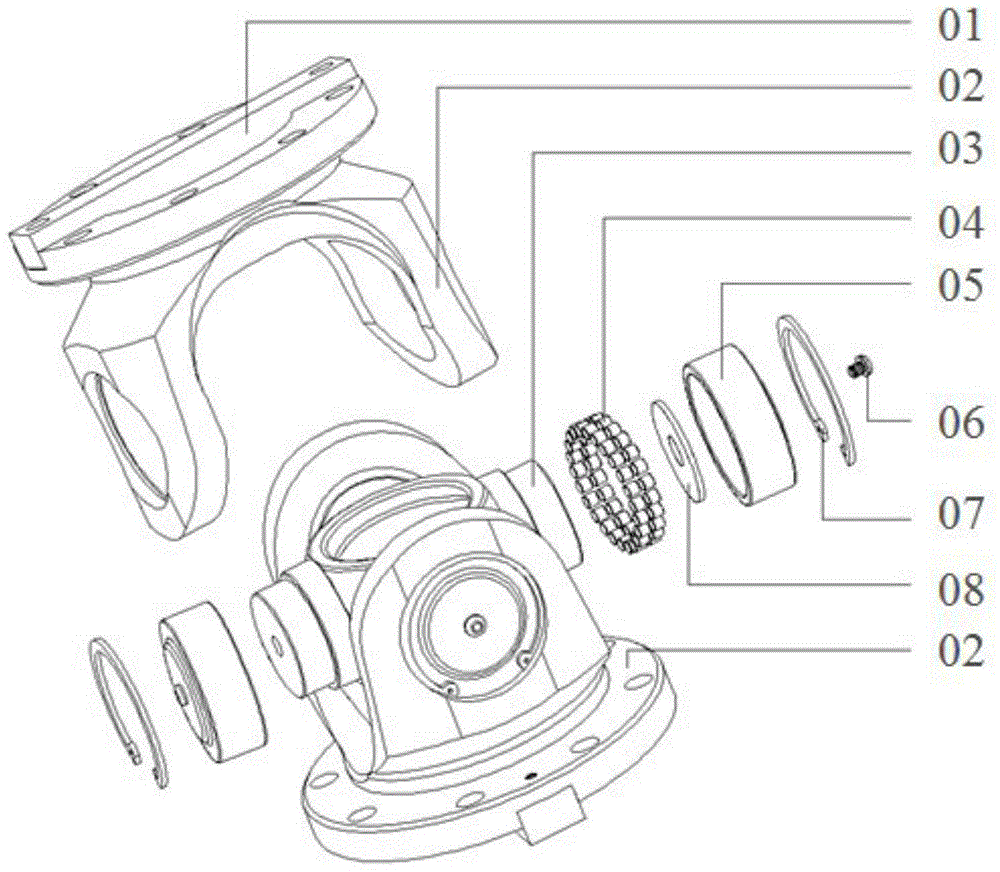

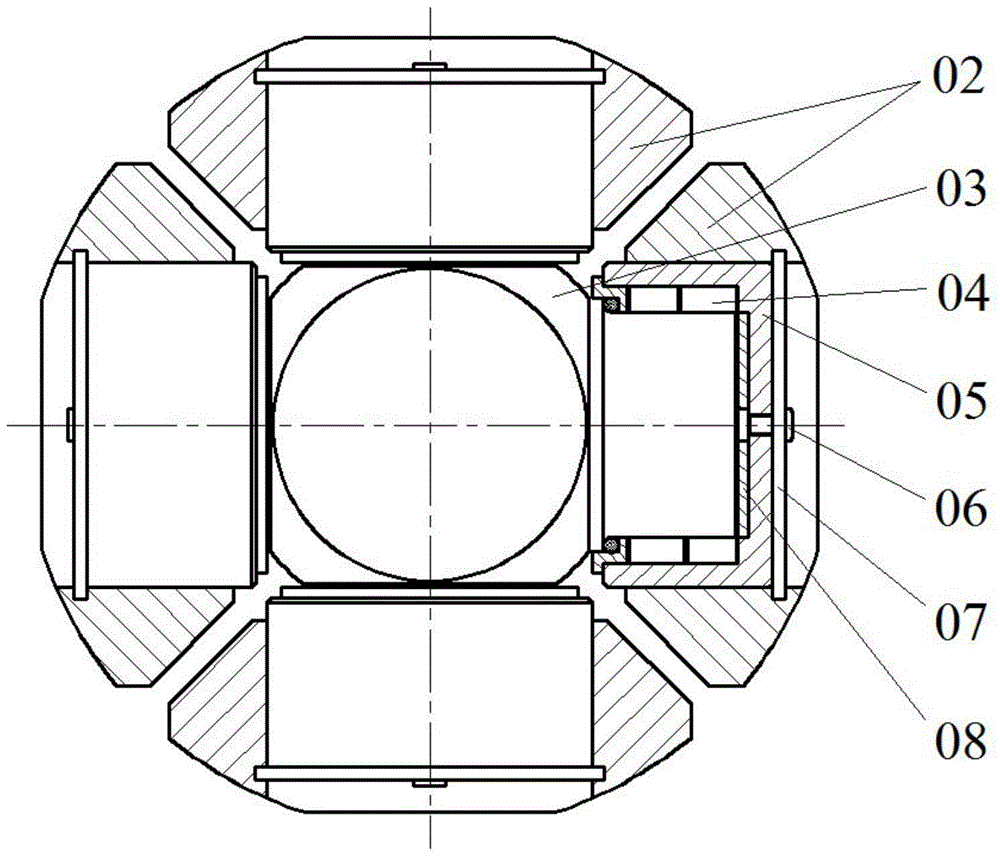

[0038] Such as Figure 4 - As shown in -6, the double-leaf shaft type universal coupling of the present invention is composed of two opposite and 90° cross-mounted double-leaf shaft forks 2 installed in the housing 3; Figure 7 Among them, the shape of the double-leaf shaft fork 2 is saddle-shaped, the lower base is a flange 2-6, and the flange 2-6 is provided with an end face key 1 for strengthening and fixing; the upper part is two coaxial The outwardly protruding shaft head 2-1; the shaft shoulder 2-5 is provided with a sealing ring 6 as dust protection. Figure 8 Among them, the housing 3 is a hollow waist drum shape, and a through hole is opened in the axial center, so that the shaft head 2-1 of the double-leaf shaft fork 2 can be inserted into the cavity of the drum-shaped body for installation; the circumferential wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com