Device and method for detecting geometric errors of single-axis motions of machine tool

A technology of geometric error and detection equipment, which is applied in the direction of measuring devices, instruments, and optical devices, etc., can solve problems such as the inability to meet the processing accuracy of CNC machine tools, the inability of CNC machine tools to effectively identify geometric errors, and the identification accuracy not meeting the requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

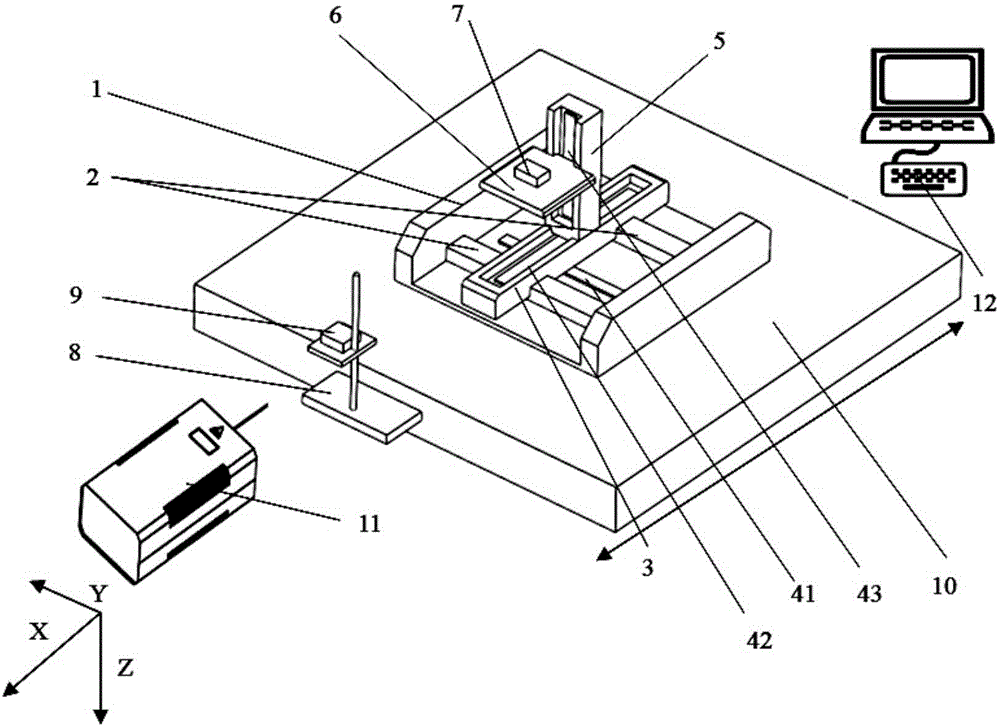

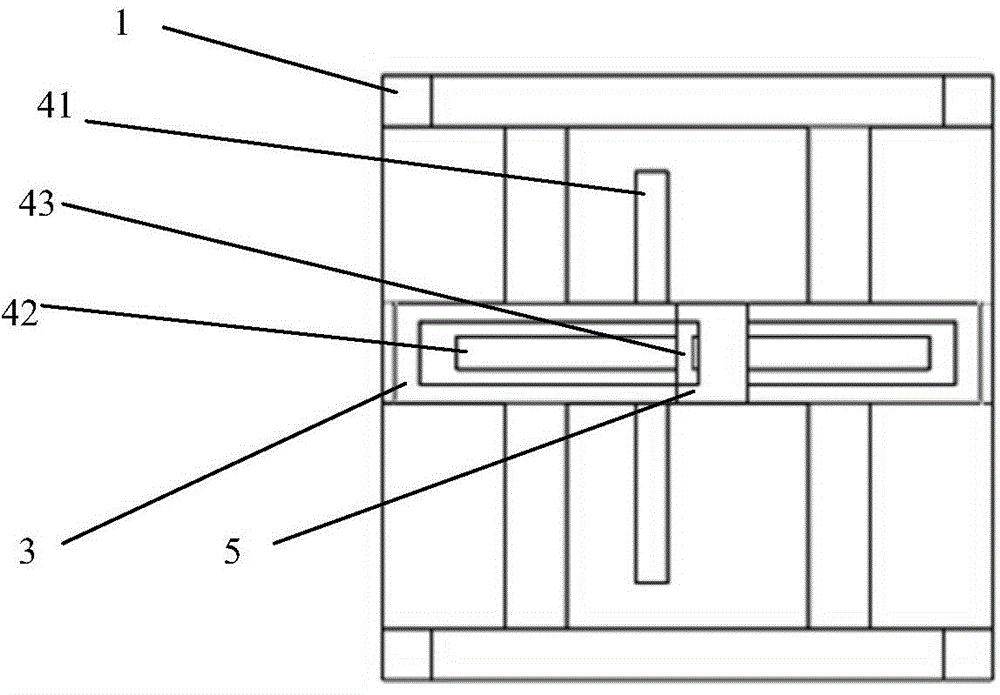

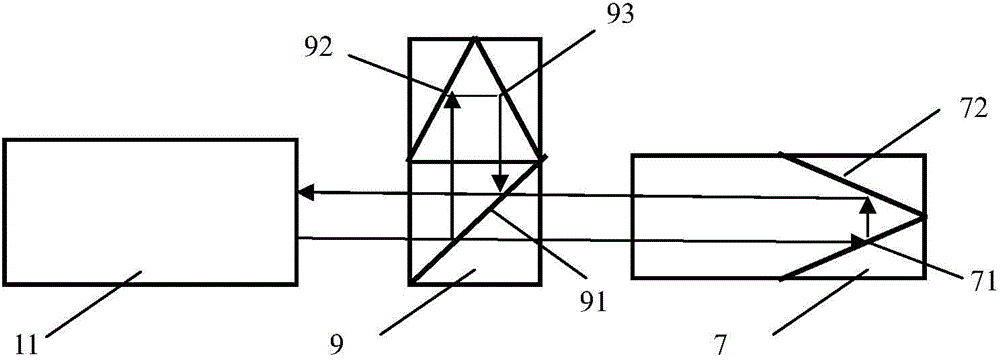

[0066] refer to Figure 1 ~ Figure 3 , a geometric error detection device for single-axis motion of a machine tool, including a processor 12, a laser interferometer 11, an interference mirror group 9, a mirror group 7, a bracket 8 for installing the interference mirror group 9, and a The fixed platform 1 on the single axis 10, the lower part of the fixed platform 1 is provided with a sliding guide rail 2 horizontally, and the sliding guide rail 2 is provided with a Y guide rail 3 which is perpendicular to the slide guide rail 2 and can slide along the slide guide rail 2, and on the Y guide rail 3 An X-guiding rail 5 that is perpendicular to the Y-guiding rail 3 and can slide along the Y-guiding rail 3 is provided, and a Z-directing sliding platform 6 that is perpendicular to the X-guiding rail 5 and can slide along the X-guiding rail 5 is provided on the X-guiding rail 5; And the mirror group 7 can move along the X-axis direction, the Y-axis direction and the Z-axis direction ...

Embodiment 2

[0074] The detection method of the detection device for the geometric error of the single-axis motion of the machine tool described in Embodiment 1 includes:

[0075] S1, refer to Figure 4 , taking the direction of the sliding guide rail 2 as the X axis, the direction of the X guide rail 5 as the Y axis, and the direction of the Y guide rail 3 as the Z axis, after the spatial coordinate system is established, the origin of the spatial coordinate system is selected, and the single axis of the machine tool is driven 10 moves along the X-axis direction; here, the origin of the space coordinate system is generally selected as the intersection of the sliding guide rail 2, the X-guiding rail 5 and the Y-guiding rail 3.

[0076] S2. By adjusting the Y guide rail 3 and the Z sliding platform 6, the reflector group 7 is located in three different positions, and at the same time, at each position, the machine tool is driven to move along the X axis so that the reflector group 7 moves l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com