A kind of color development method of hydrogen-containing hypophosphite

A technology of hydrogen hypophosphite and phosphate, which is applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions, which can solve the problem of low selectivity and low sensitivity of chromogenic agents , Weak color rendering and other problems, achieve the effect of high color sensitivity, fast and clear color rendering, and reduce workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

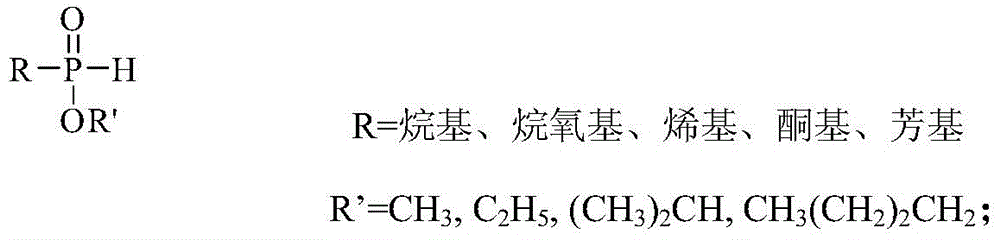

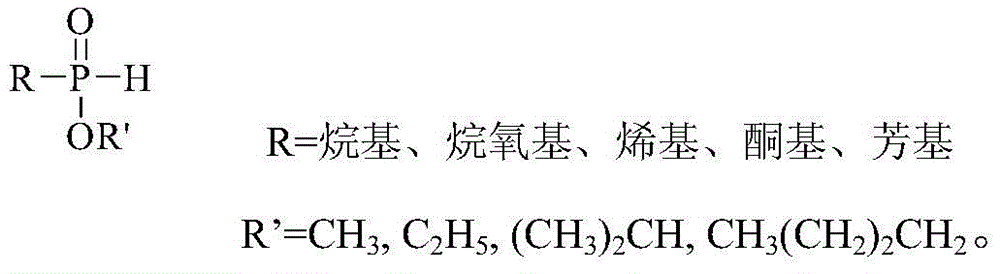

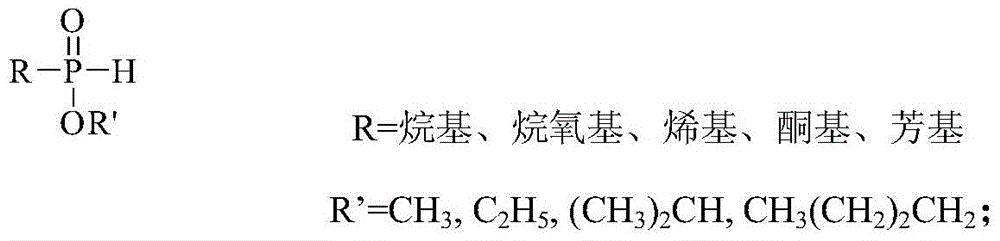

[0016] The selective color development method is as follows: after soaking the silica gel sheet in the color developer, after drying and iodine fumigation, the hydrogen-containing hypophosphite shows a clear dark blue, the phosphate shows a weak light blue, and the remaining ketones, Acids, amines, and carboxylic acid esters do not show color;

[0017]

[0018] The method steps are as follows:

[0019] 1) Color developer soaking: The color developer of this method includes 1-6 g of phosphomolybdic acid or cerium ammonium molybdate or ammonium molybdate, dissolved in 5-10 mL of distilled water, and added with 2-10 mL of concentrated hydrochloric acid or perchloric acid Or concentrated sulfuric acid, dilute to 100mL with acetone, water or ethanol, infiltrate the expanded silica gel sheet, and take it out after infiltration;

[0020] 2) Drying: the soaked sheet is blown dry with a hot air blower and heated to 100-150°C. As the temperature increases, the silica sheet changes f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com