Probe and testing device

A probe and electrical testing technology, applied in the field of probes and test equipment, can solve the problems of poor test signal, unstable pin body 1, inaccurate test, etc., to improve test efficiency and test accuracy, and to adjust easily Fast, accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

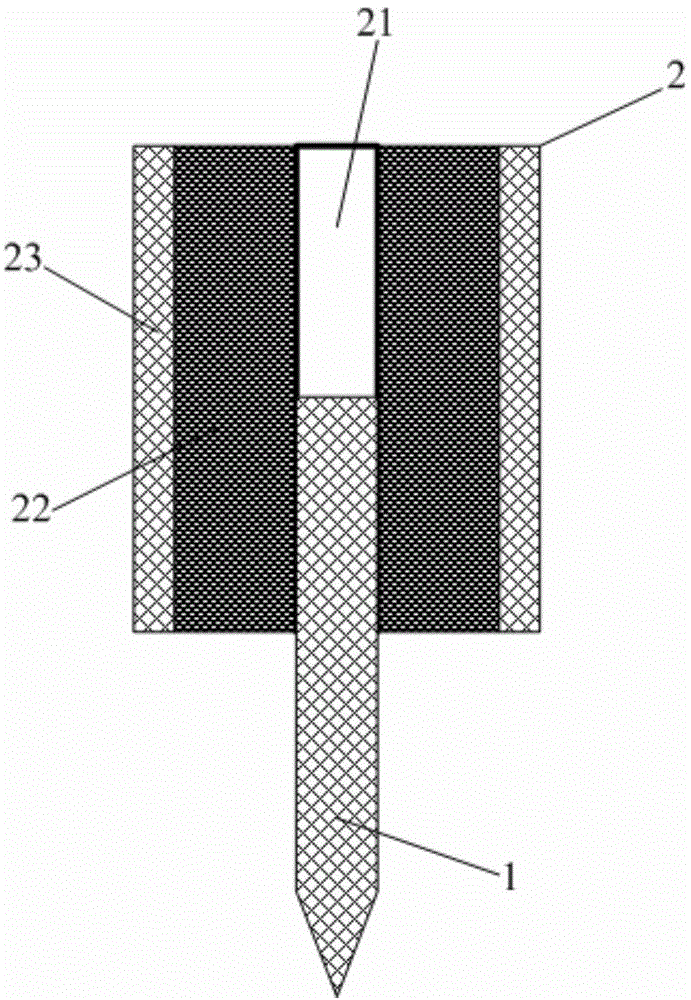

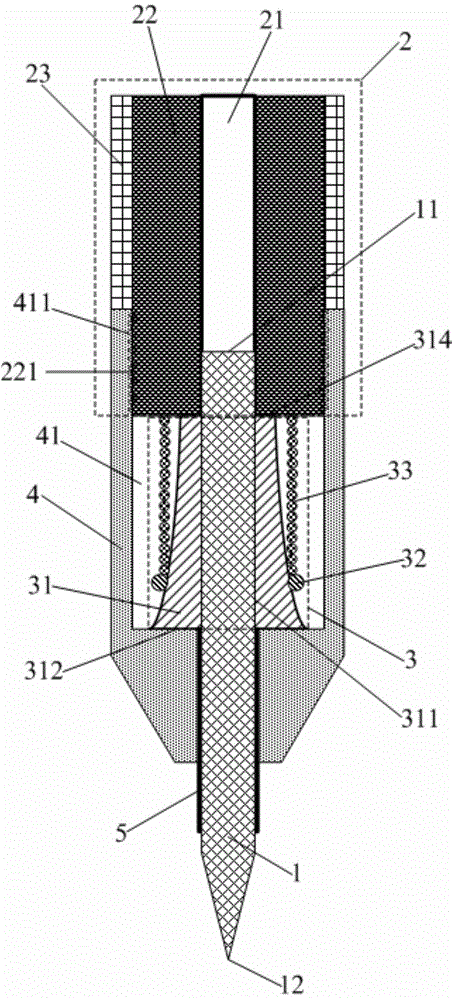

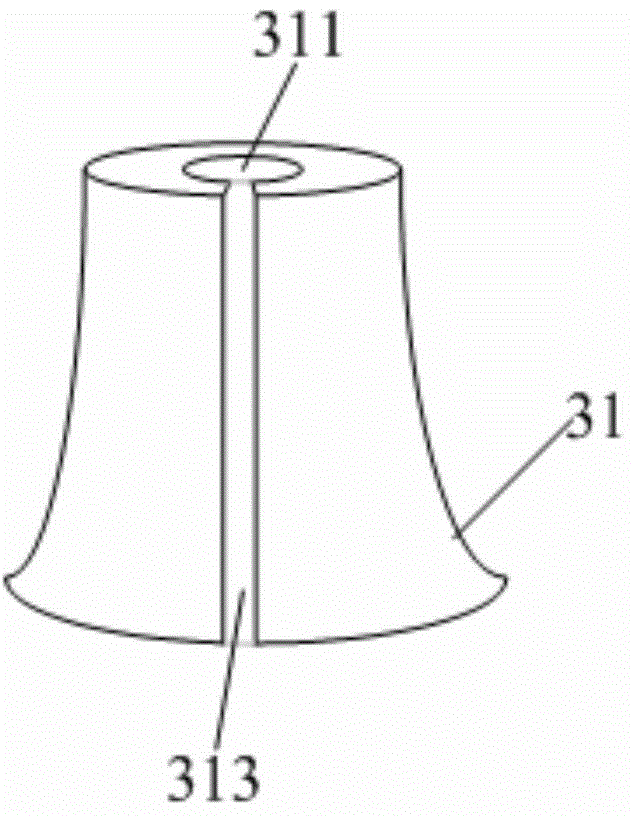

[0030] This embodiment provides a probe for electrical testing, such as Figure 2-5 As shown, it includes a needle body 1 and a signal wire 2. The signal wire 2 includes a wire core 21 and an insulating layer 22 wrapped around the wire core 21. The first end 11 of the needle body 1 is connected to the wire core 21, and the second end of the needle body 1 The end 12 is exposed for testing and also includes a clamping structure 3 for clamping the needle body 1 .

[0031] The setting of the clamping structure 3 can make the needle body 1 be firmly clamped, so that the needle body 1 is not easy to be unstable or run away during the test process, ensuring that the test signal can be introduced normally, thereby not only ensuring the signal test Accuracy, but also improve the efficiency of signal testing.

[0032] In this embodiment, the wire core 21 is a conductive hollow tube wrapped inside the insulating layer 22 , and the inner diameter of the hollow tube is equal to the diamet...

Embodiment 2

[0043] This embodiment provides a probe for electrical testing. The difference from Embodiment 1 is that the clamping structure in this embodiment only includes a cone and does not include a pressure ring and a spring. Wherein the structure of the frustum is the same as in Example 1.

[0044] Since the cone is made of rubber or plastic material and has a certain degree of elasticity, it can keep the needle body clamped so that the needle body is not easy to be unstable or run out of the needle.

[0045] Other structures and materials of the probe in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

[0046] Beneficial effects of embodiment 1-2: the probe in embodiment 1-2, by setting the clamping structure, the needle body can be firmly clamped, so that the needle body is not easy to be unstable or run out during the test phenomenon, to ensure that the test signal can be introduced normally, thereby not only ensuring the accuracy of the sig...

Embodiment 3

[0048] This embodiment provides a testing device, including the probe in any one of Embodiments 1-2.

[0049] By using the probe in any one of the embodiments 1-2, the testing efficiency and testing accuracy of the testing equipment are improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com