Steam-driven phosphoric acid system cleaning fluid preparation device with temperature control linkage function

A steam-driven, cleaning fluid technology, applied in transportation and packaging, mixer accessories, dissolution, etc., can solve the problems of high labor intensity, long maintenance time, low production efficiency, etc., to reduce labor intensity, reduce production costs, The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

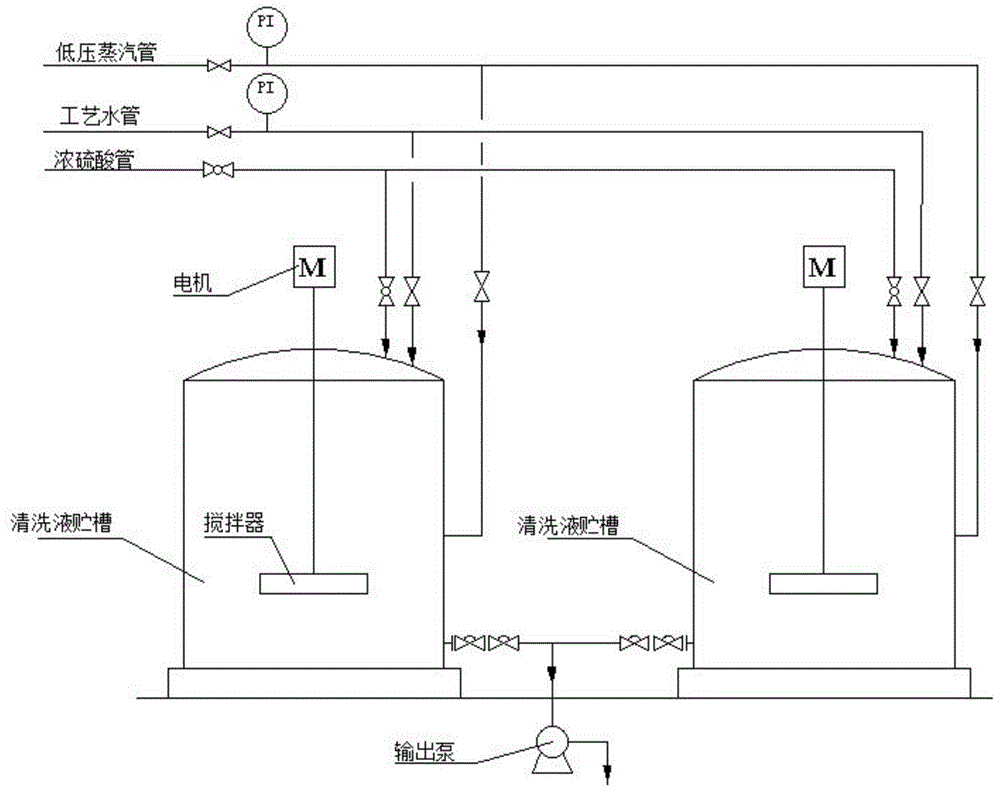

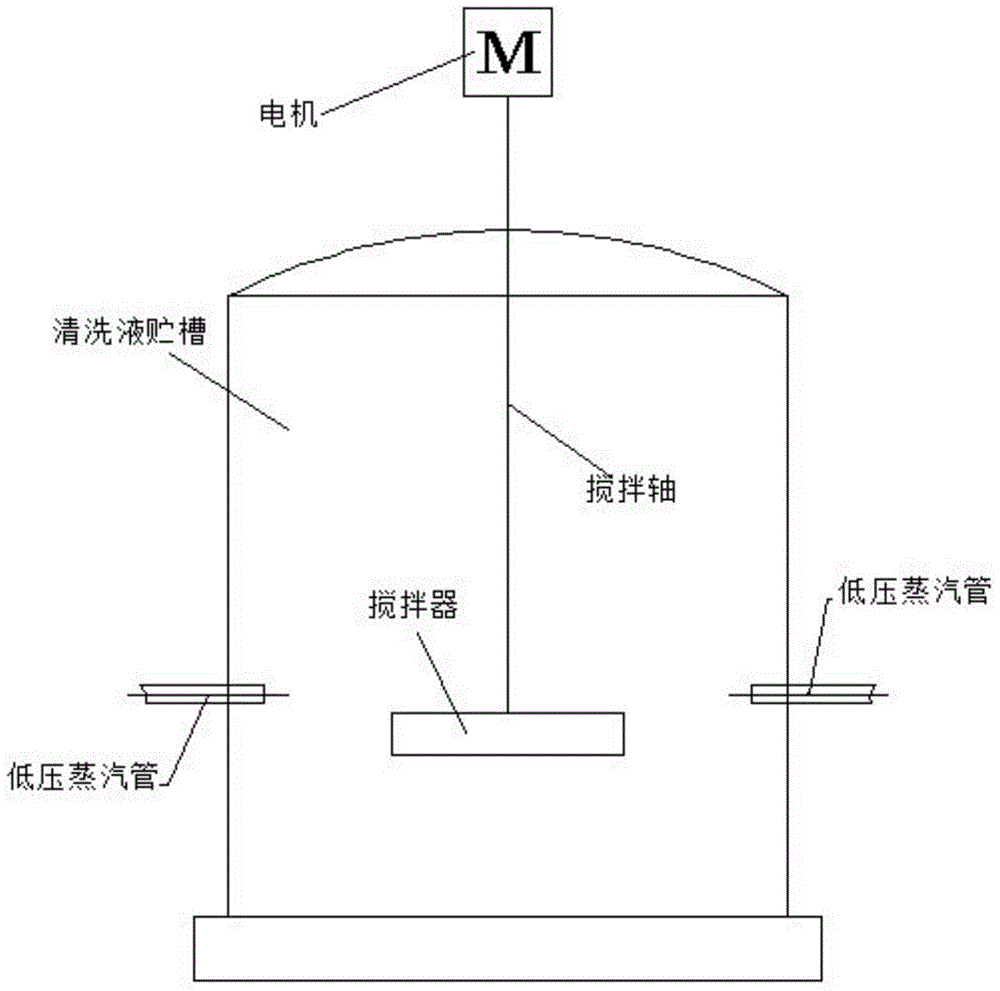

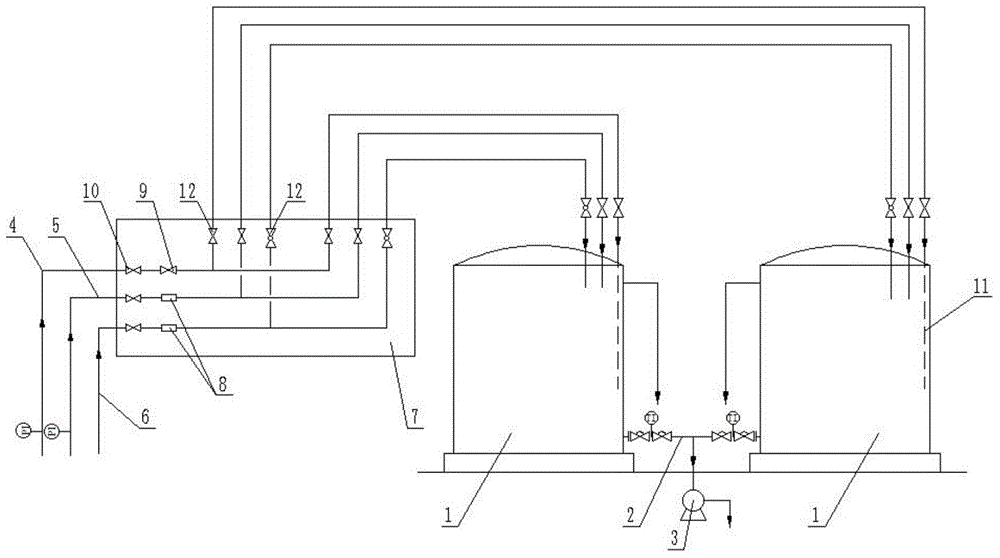

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: When only a single storage tank 1 needs to be prepared:

[0045] Close the control valve 12 on the low-pressure steam pipe 4, the process water pipe 5 and the concentrated sulfuric acid pipe 6 connected to one of the two storage tanks 1. At this time, only one of the two storage tanks 1 can be used for infusion preparation. The main valve 10 on the low-pressure steam pipe 4, the process water pipe 5 and the concentrated sulfuric acid pipe 6, the concentrated sulfuric acid and the process water are input into the storage tank 1 together. During the transportation, the low-pressure steam pipe 4 transports the steam to the tail section of the steam pipe 11. The tail section 11 of the steam pipe is inserted into the storage tank 1. Since the four steam pipe tail sections 11 are evenly distributed along the circumference of the storage tank 1, and the angle between the elbow 103 and the tangent line of the circumference is 18°, the steam is transported to After...

Embodiment 2

[0046] Embodiment 2: When it is necessary to prepare two storage tanks 1 at the same time:

[0047]Simultaneously open all operating valves 12 on the operating platform 7, open the main valve 10 on the low-pressure steam pipe 4, the process water pipe 5 and the concentrated sulfuric acid pipe 6, the concentrated sulfuric acid and the process water are input in the two storage tanks 1 together, and are transported During the process, the low-pressure steam pipe 4 transports the steam to the tail section 11 of the steam pipe. The angle between the tangents of the circumference is 18°. After the steam is transported into the storage tank 1, it will form a swirling flow after being output through the elbow 103, and the process water and concentrated sulfuric acid in the storage tank 1 will be stirred and kept warm. During the preparation process, the flow meter 8 and the pneumatic valve 9 installed on the operation platform 7 can be used to monitor the process water, concentrated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com