Automatic sorting system for electric energy meters, and method

An automatic sorting system and electric energy meter technology, applied in sorting and other directions, can solve the problems of low reliability, wrong identification, and expensive robot vision solutions, so as to improve the grasping efficiency and grasping reliability, and reduce labor. Strength, the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

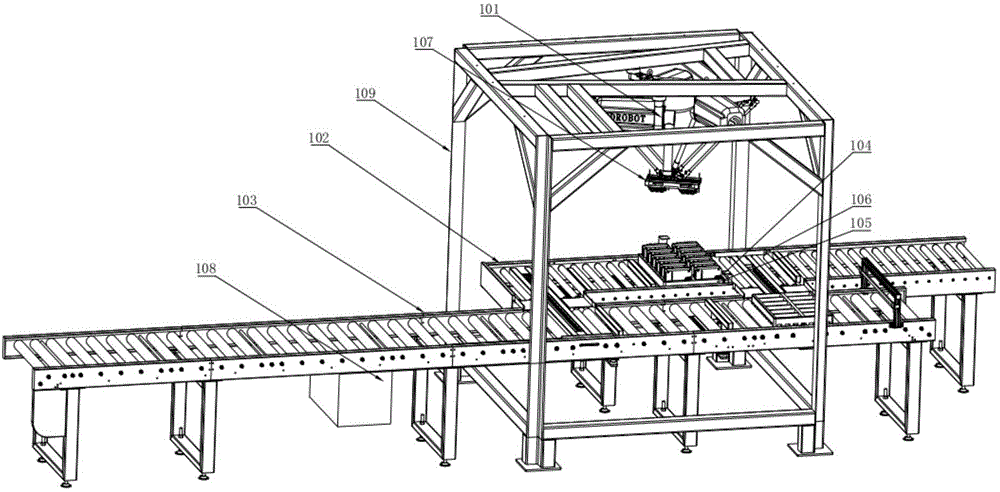

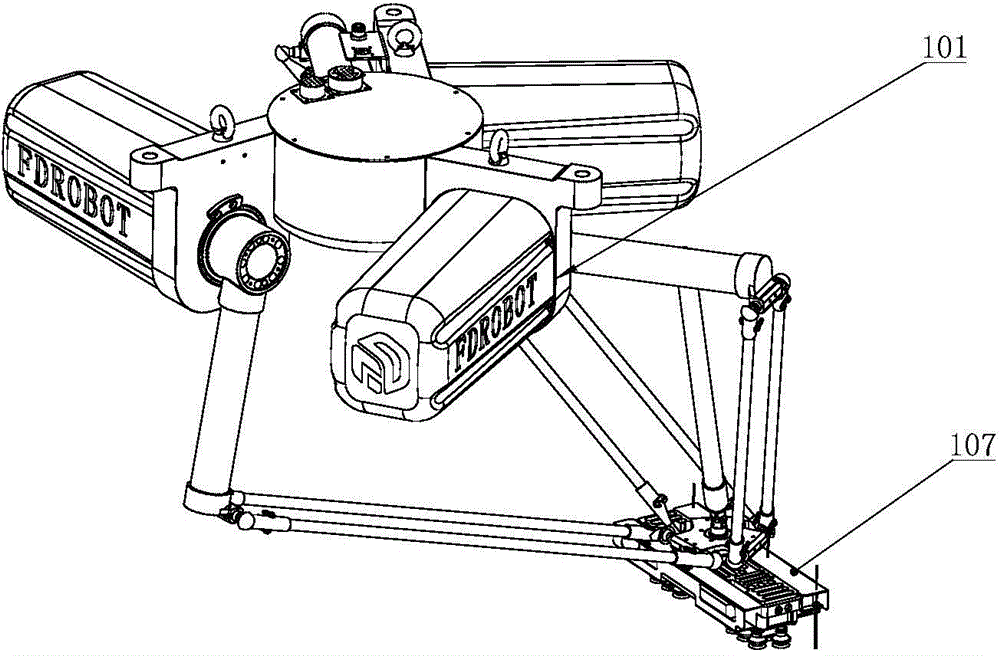

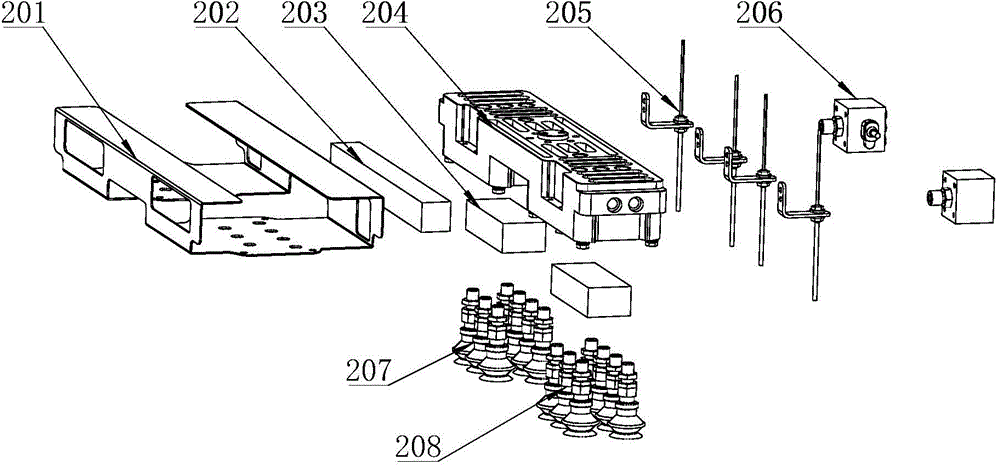

[0048] Such as Figure 1 to Figure 5 As shown: an automatic sorting system for electric energy meters provided by the present invention, including a full-case conveying line 102, an empty-case conveying line 103, a control system, a Delta robot 101 connected to the control system, a carton blocking device 104, and a carton clamping system. device, carton rejecting device 106, intelligent gripper 107 and frame 109;

[0049] The full-case conveying line 102 transports the electric energy meter box after unpacking to the electric energy meter sorting place;

[0050] The carton blocking device 104 is used to block the electric energy meter box;

[0051] The carton clamping device is used to clamp and fix the carton of the electric energy meter box;

[0052] The carton blocking device 104, the carton clamping device and the carton rejecting device 106 are fixed on the full-case conveying line 102;

[0053] The Delta robot first scans the packing state of the electric energy mete...

Embodiment 2

[0080] The difference between this embodiment and embodiment 1 is only:

[0081] The front and back detection sensors of the electric energy meter can be arranged on the intelligent gripper 107 to detect the front and back information of the electric energy meter and the packing position information of the electric energy meter. The detection of the positive and negative information of the electric energy meter and the packing position information of the electric energy meter is realized through the movement of the intelligent gripper 107 and the Delta robot 101 . The positive and negative detection of the electric energy meter is realized by detecting the opening direction of the head and the tail of the electric energy meter; when detecting the electric energy meter packed in a reverse direction of 180 degrees, the Delta robot 101 can rotate the electric energy meter around the Z axis through the fourth axis to turn the direction of the electric energy meter forward.

[0082...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com